Conteúdo do produto

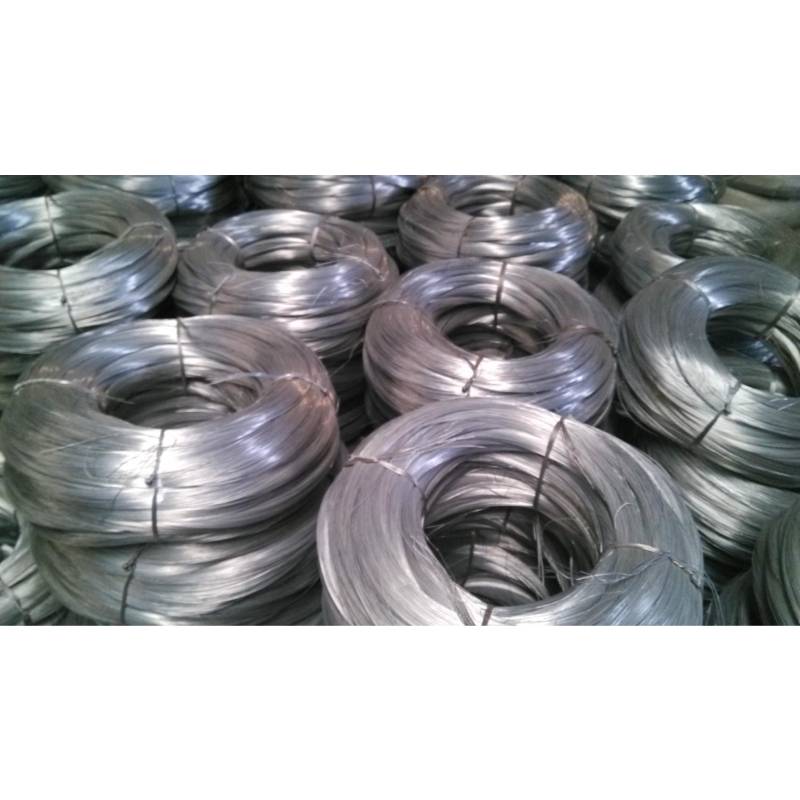

Arame galvanizado

1.Tipo: Eletro ou galvanizado por imersão a quente

2.MOQ: 3 toneladas

3.Principal área de exportação: Europa Ocidental, América, Oriente Médio

We can supply super quality Electro Galvanized Iron Wire/ Hot Dipped Galvanized Wire processed with low/hign carbon steel wire, through drawing and electro Galvanized.

Our Shijiazhuang tangchao metal products co.LTD produces Galvanized Wire from choiced low/high carbon steel wire,

through the strict process of wire drawing-annealing-acid washing-water clearing-drying-galvanizing coiling,

in this way, excellent flexibility and tensile strength could be guaranteed.

Electro/Hot Dipped Galvanized Wire Technical/Mechanical Characters:

ASTM Standard: A641/A641M-98

Material: SAE1006/1008,Q195/235 SAE1050/1065

Standard wire gauge BWG6 to BWG25.

Zinc coating: 8-25g/sqm for Electro Galvanized Wire; 60g - 220g/sqm for Hot Dipped Galvanized Wire

Heavy coating: >200grams/sq.m or according to our customers' requirement >250grams/sq.m

T.S.: 300/550Mpa, 350/450Mpa, 450-550Mpa, 600-800Mpa, 700-900Mpa 1100-1300Mpa, 1300-1700Mpa etc.

Packing: 1kg-1000kgs/coil

Application: This kind of wire is extensively used in construction, handicrafts, woven wire mesh, express way fencing mesh, packaging of products and other daily uses.

Cenários de aplicação de produto

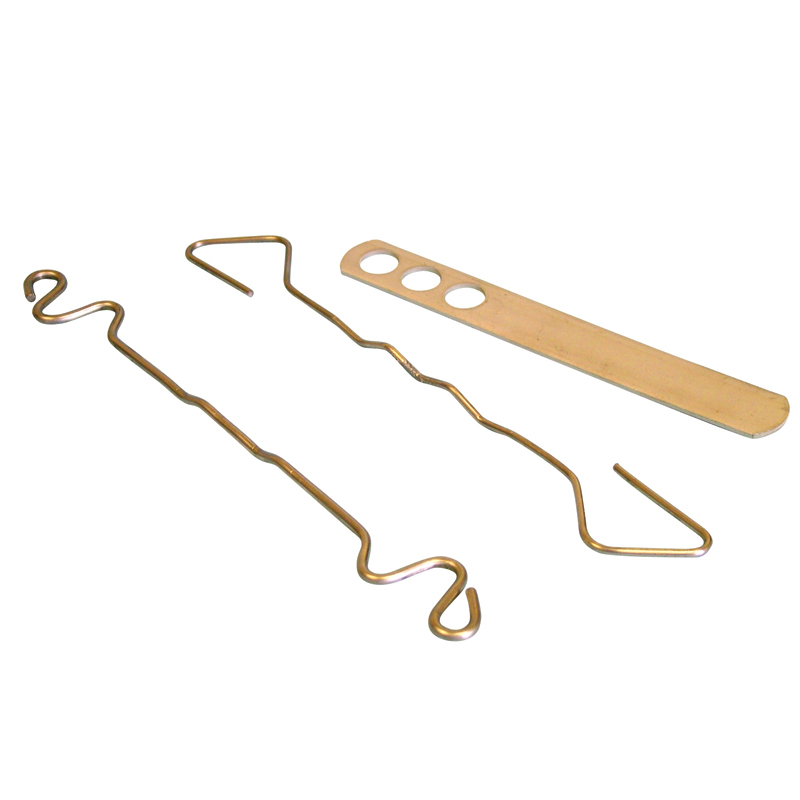

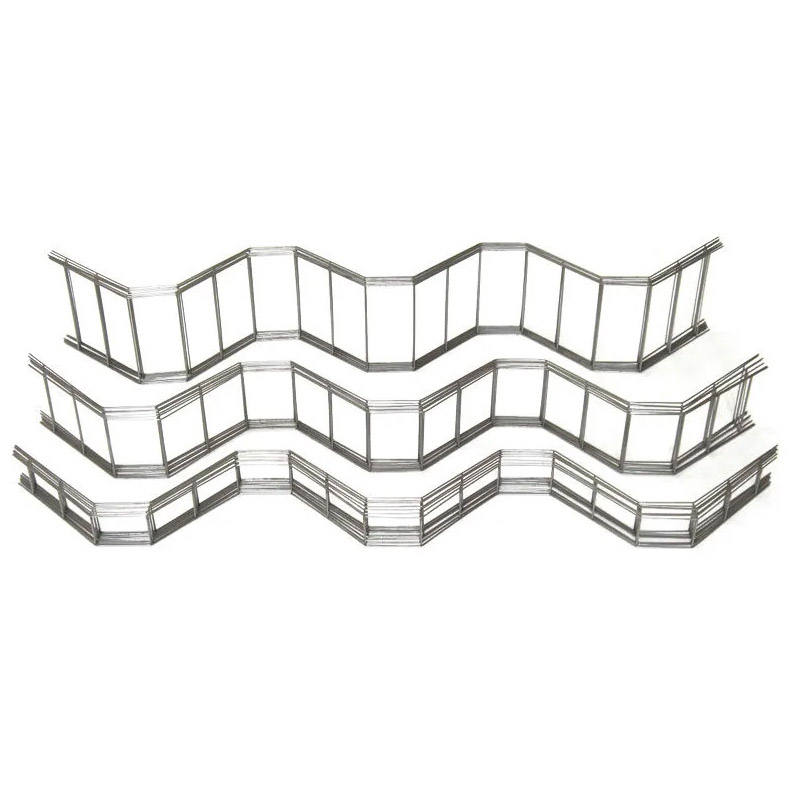

Galvanized iron wire is widely used in various industries, including construction, horticulture, and manufacturing. In construction, galvanized steel wire is commonly used for binding reinforcement bars, constructing shelves, and fixing fences due to its excellent corrosion resistance. In horticulture, galvanized tie wire can be used for creating garden structures, supports for plants, and binding branches securely. In manufacturing, hot-dipped galvanized wire is popular for weaving wire meshes, creating wire products, or serving as a durable component in other metal structures. If you are looking for galvanized wire for sale, our products come with guaranteed quality and competitive galvanized wire prices.

Processo de produção do produto

O processo de produção de fio de ferro galvanizado normalmente envolve as seguintes etapas:

1. Wire drawing: High-strength low-carbon steel wire is drawn through a wire drawing machine to achieve the desired diameter of the wire.

2. Pickling: The drawn wire is subjected to pickling to remove surface oxides and impurities, preparing the surface for the galvanizing process.

3. Galvanizing: The pickled wire is dipped into a molten zinc bath to coat the surface with a layer of zinc. This step provides corrosion resistance and durability to the wire.

4. Cooling: The galvanized wire is allowed to cool, solidifying the zinc coating and creating a uniform surface.

5. Winding: The cooled galvanized wire is wound into rolls for convenient storage and transportation.

Where Is Galvanized Iron Wire Used?

Among the many wire products available today, galvanized iron wire stands out for its adaptability, strength, and corrosion resistance. Thanks to its zinc coating, this wire is designed to perform reliably in challenging environments, making it a go-to material across construction, agriculture, and manufacturing industries. When exploring practical galvanized iron wire uses, one quickly discovers its far-reaching value.

In the construction sector, galvanized iron wire is frequently used for tying reinforcement bars, installing fences, and forming structural frameworks. It offers a high level of durability in wet or chemically aggressive environments, making it ideal for outdoor and underground applications. Variants like galvanized tie wire are especially favored on construction sites for their excellent binding capacity and rust resistance.

In agriculture and horticulture, this wire supports a wide range of uses—from building trellises and garden enclosures to livestock fencing and crop supports. Soft galvanized wire is often preferred for its easy handling and flexibility, while still offering long-term weather resistance. Farmers and landscapers rely on it for low-maintenance, high-strength solutions that stand up to the elements.

Manufacturing applications also benefit greatly from galvanized iron wire. It is a preferred choice for making galvanized wire mesh, wire forms, cage structures, and packaging ties. The wire’s uniform surface and mechanical strength allow it to be efficiently processed in automated machinery.

At Shijiazhuang TangChao Metal Products Co., Ltd., we specialize in producing galvanized wire products that meet global quality expectations. Founded in 1998 and based in Hebei Province, our 7,000-square-meter facility uses advanced machinery imported from Germany, Korea, and Taiwan. This ensures precision, consistency, and durability in every coil we produce.

Exporting to over 15 countries—including the USA, Australia, Japan, and the EU—TangChao has built a reputation as a reliable supplier of hot dipped galvanized wire and other specialty forms. Whether for structural work or agricultural support, our wire is engineered to last.

Looking for galvanized wire for sale? At TangChao, we don’t just deliver wire—we deliver performance, backed by decades of expertise and commitment to quality.

How to Choose Iron Wire Manufacturers?

Finding the right galvanized iron wire manufacturers can be the key to project efficiency and product reliability. With a market full of generic suppliers, the real challenge lies in sourcing from a company that not only delivers wire—but also delivers trust, consistency, and long-term support.

Here are three critical elements that define a reliable manufacturer:

Production Capability and Technical Depth

Since 1998, Shijiazhuang TangChao Metal Products Co., Ltd. has established itself as a trusted wire manufacturer based in Hebei Province, China. With a 7,000-square-meter facility and a dedicated team of 30 technical professionals, we specialize in a wide range of products, from galvanized iron binding wire to advanced steel wire galvanized solutions. Our annual output exceeds 22 million RMB, reflecting both our scale and stability.

Advanced Equipment, Global Standards

TangChao imports production equipment from Germany, Korea, and Taiwan to ensure technological precision at every stage. Whether we are drawing, annealing, or hot-dip galvanizing, our processes are tightly controlled to meet international benchmarks. This ensures consistent quality, even across large-volume orders.

International Footprint and Service Support

TangChao is not only a domestic supplier—we’re a global exporter. Our galvanized wire products are widely used in the USA, EU, Australia, Japan, and the Middle East. As a galvanized iron wire manufacturer with over two decades of global service experience, we offer full customization, fast delivery, and multilingual support to clients worldwide.

Whether you're a construction contractor or an industrial buyer, working with the right supplier affects everything—from project safety to profit margins. Some galvanized wire suppliers may promise cheap prices, but lack in durability and consistency. At TangChao, we believe in balancing value with verified performance.

From galvanized binding wire to precision-formed coils, we deliver products that are built to perform and priced to compete. Partnering with a proven manufacturer like TangChao means getting more than just materials—you get a solution that grows with your needs.

What Sizes Does Galvanized Wire Come In?

When selecting galvanized wire, size matters—not just for fitting specifications but also for performance, handling, and safety. From thin, flexible strands used in gardening to thick, load-bearing gauges for heavy-duty construction, choosing the right wire diameter ensures optimal results.

At Shijiazhuang TangChao Metal Products Co., Ltd., we produce galvanized wire in a wide range of diameters to suit global needs. Our most popular offerings include:

•12 gauge galvanized steel wire: A strong, medium-thick wire ideal for fencing, structural framing, and forming cages.

•9 gauge galvanized wire: Used for heavy-duty agricultural applications and high-tension barriers.

•14 gauge galvanized wire: Preferred in horticulture and light-duty construction for its ease of bending and corrosion resistance.

•16 gauge galvanized tie wire: Lightweight but tough, often used for bundling or rebar tying in construction.

In metric sizes, 4mm galvanised wire and 2.5mm soft galvanized wire are also popular among customers who require European standard dimensions.

Wire thickness affects more than just application—it influences tensile strength, flexibility, and price. That’s why TangChao ensures every size complies with international specifications and is subject to strict quality checks.

With our precision manufacturing setup, we can deliver custom diameters to meet client-specific requirements. Our galvanized wire for sale ranges from ultra-fine to heavy gauge options, all produced with a smooth zinc coating that enhances both longevity and workability.

Whether you're sourcing 10 gauge galvanized steel wire for mesh production or 16 gauge galvanized steel wire for light-duty frameworks, TangChao offers dependable sizing, competitive galvanized wire price, and consistent quality.

Don't let mismatched sizes delay your projects. Choose a supplier that understands the importance of fit and function. With TangChao, every wire is crafted to specification—and built to last.