Product Content

Filum Galvanized

1.Type: Electro vel Hot detritum galvanized

2.MOQ: 3tons

3. Praecipua Export Area: Europa occidentalis, America, Oriens Medius

We can supply super quality Electro Galvanized Iron Wire/ Hot Dipped Galvanized Wire processed with low/hign carbon steel wire, through drawing and electro Galvanized.

Our Shijiazhuang tangchao metal products co.LTD produces Galvanized Wire from choiced low/high carbon steel wire,

through the strict process of wire drawing-annealing-acid washing-water clearing-drying-galvanizing coiling,

in this way, excellent flexibility and tensile strength could be guaranteed.

Electro/Hot Dipped Galvanized Wire Technical/Mechanical Characters:

ASTM Standard: A641/A641M-98

Material: SAE1006/1008,Q195/235 SAE1050/1065

Standard wire gauge BWG6 to BWG25.

Zinc coating: 8-25g/sqm for Electro Galvanized Wire; 60g - 220g/sqm for Hot Dipped Galvanized Wire

Heavy coating: >200grams/sq.m or according to our customers' requirement >250grams/sq.m

T.S.: 300/550Mpa, 350/450Mpa, 450-550Mpa, 600-800Mpa, 700-900Mpa 1100-1300Mpa, 1300-1700Mpa etc.

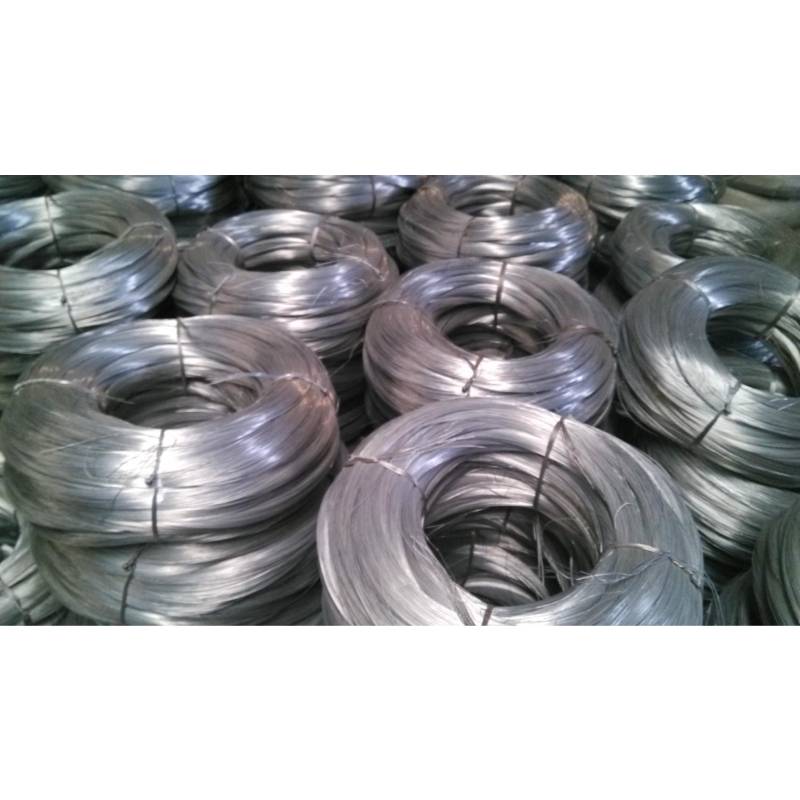

Packing: 1kg-1000kgs/coil

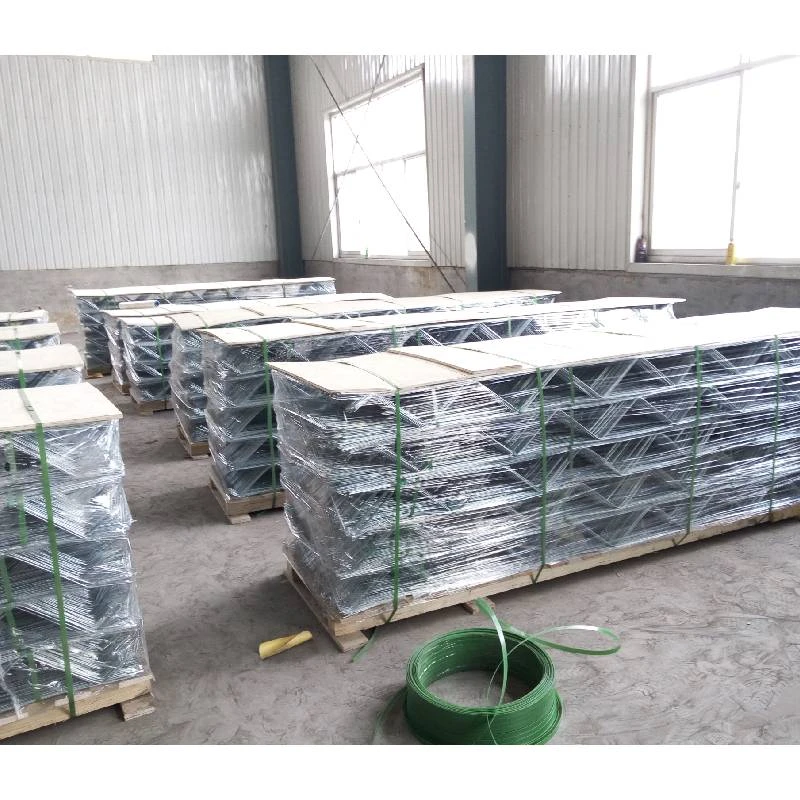

Application: This kind of wire is extensively used in construction, handicrafts, woven wire mesh, express way fencing mesh, packaging of products and other daily uses.

Product Application missiones

Filum ferreum Galvanisatum late in variis industriis, in constructione, in hortis, et in fabricandis, adhibetur. In constructione, vulgo ad vecturas subsidii ligandas, crustas construendas et sepes muniendas. In horticultura adhiberi potest ad structuras horti conficiendas, sustentationes ad plantas, et ad colligandas ramos. In fabricandis, adhiberi potest ad reticulum filum texendum, fructus filum creandum, vel ad component in aliis structuris metallicis.

Productio Processus

Processus productionis filum ferreum galvanizatum typice involvit sequentes gradus:

1. Wire drawing: High-strength low-carbon steel wire is drawn through a wire drawing machine to achieve the desired diameter of the wire.

2. Pickling: The drawn wire is subjected to pickling to remove surface oxides and impurities, preparing the surface for the galvanizing process.

3. Galvanizing: The pickled wire is dipped into a molten zinc bath to coat the surface with a layer of zinc. This step provides corrosion resistance and durability to the wire.

4. Cooling: The galvanized wire is allowed to cool, solidifying the zinc coating and creating a uniform surface.

5. Winding: The cooled galvanized wire is wound into rolls for convenient storage and transportation.