Produktindhold

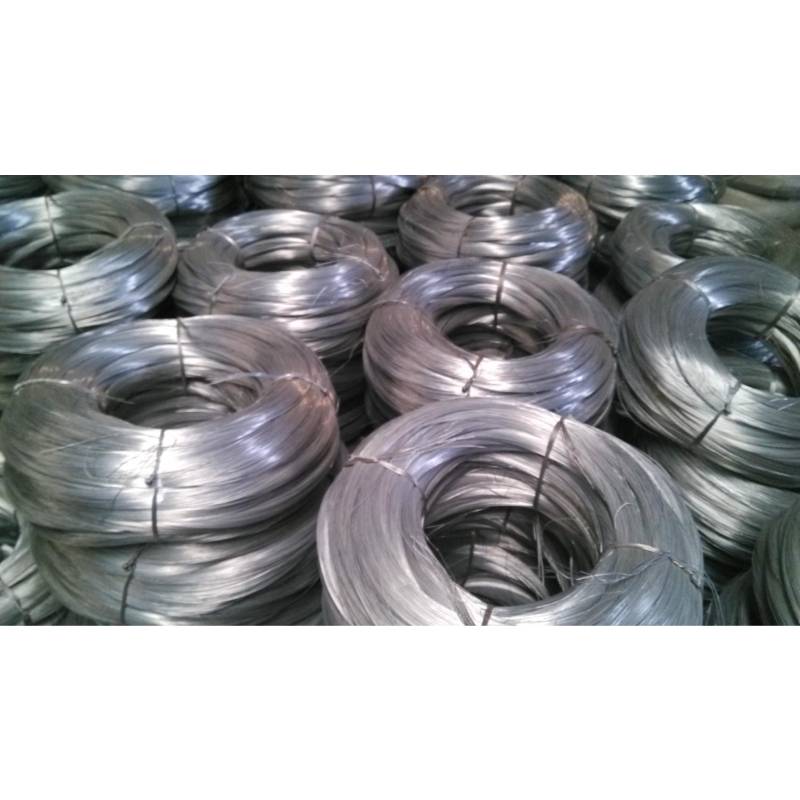

Galvaniseret tråd

1. Type: Elektro- eller varmgalvaniseret

2.MOQ: 3tons

3. Hovedeksportområde: Vesteuropa, Amerika, Mellemøsten

We can supply super quality Electro Galvanized Iron Wire/ Hot Dipped Galvanized Wire processed with low/hign carbon steel wire, through drawing and electro Galvanized.

Our Shijiazhuang tangchao metal products co.LTD produces Galvanized Wire from choiced low/high carbon steel wire,

through the strict process of wire drawing-annealing-acid washing-water clearing-drying-galvanizing coiling,

in this way, excellent flexibility and tensile strength could be guaranteed.

Electro/Hot Dipped Galvanized Wire Technical/Mechanical Characters:

ASTM Standard: A641/A641M-98

Material: SAE1006/1008,Q195/235 SAE1050/1065

Standard wire gauge BWG6 to BWG25.

Zinc coating: 8-25g/sqm for Electro Galvanized Wire; 60g - 220g/sqm for Hot Dipped Galvanized Wire

Heavy coating: >200grams/sq.m or according to our customers' requirement >250grams/sq.m

T.S.: 300/550Mpa, 350/450Mpa, 450-550Mpa, 600-800Mpa, 700-900Mpa 1100-1300Mpa, 1300-1700Mpa etc.

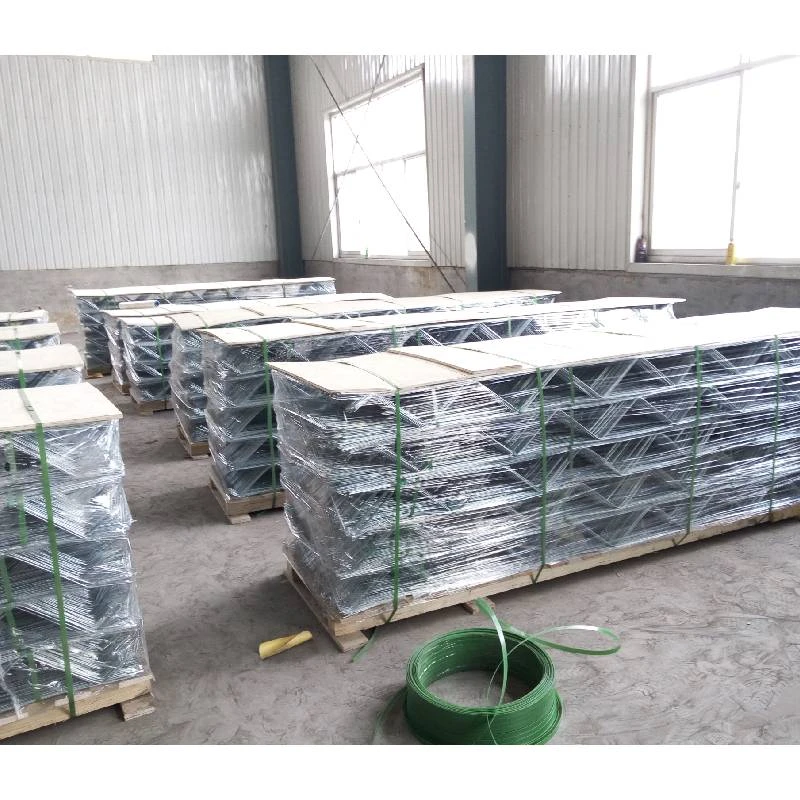

Packing: 1kg-1000kgs/coil

Application: This kind of wire is extensively used in construction, handicrafts, woven wire mesh, express way fencing mesh, packaging of products and other daily uses.

Produktapplikationsscenarier

Galvaniseret jerntråd er meget udbredt i forskellige industrier, herunder byggeri, gartneri og fremstilling. I byggeriet bruges det almindeligvis til at binde armeringsstænger, konstruere hylder og fastgøre hegn. I havebrug kan det bruges til at skabe havestrukturer, understøtninger til planter og til at binde grene sammen. I fremstillingen kan det bruges til at væve trådnet, skabe trådprodukter eller som en komponent i andre metalstrukturer.

Produktproduktionsproces

Produktionsprocessen af galvaniseret jerntråd involverer typisk følgende trin:

1. Wire drawing: High-strength low-carbon steel wire is drawn through a wire drawing machine to achieve the desired diameter of the wire.

2. Pickling: The drawn wire is subjected to pickling to remove surface oxides and impurities, preparing the surface for the galvanizing process.

3. Galvanizing: The pickled wire is dipped into a molten zinc bath to coat the surface with a layer of zinc. This step provides corrosion resistance and durability to the wire.

4. Cooling: The galvanized wire is allowed to cool, solidifying the zinc coating and creating a uniform surface.

5. Winding: The cooled galvanized wire is wound into rolls for convenient storage and transportation.