Spiraltrådsfjeder

What Are The Three Types Of Coil Springs?

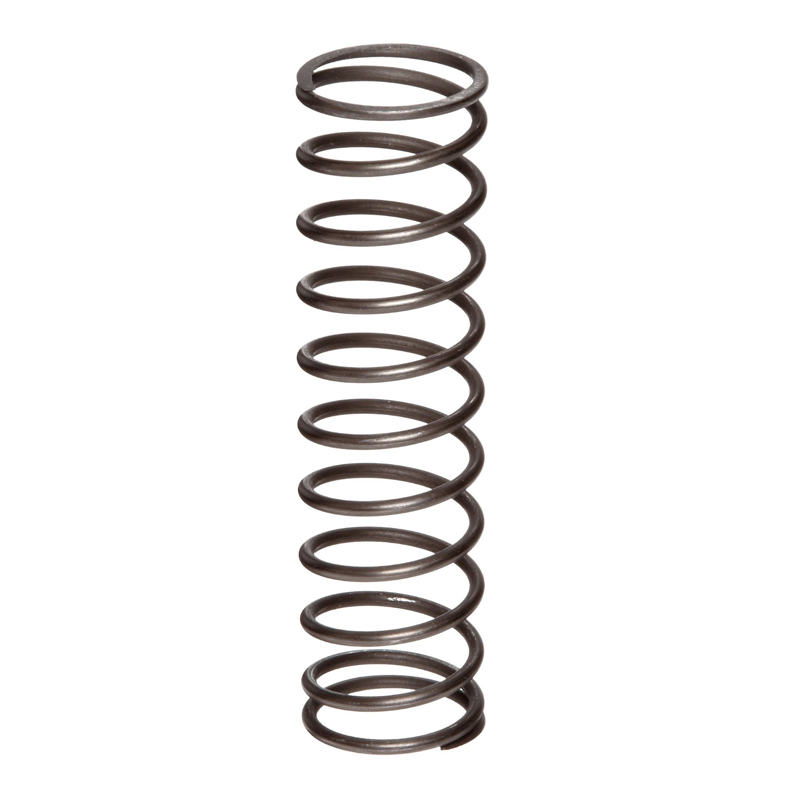

Coil wire springs are essential components in various mechanical systems, providing flexibility, resilience, and support. These springs are designed to store and release energy, making them crucial in applications ranging from automotive to industrial machinery. Understanding the different types of coil springs is vital for engineers, designers, and hobbyists alike. In this article, we will explore the three primary types of coil springs: compression springs, extension springs, and torsion springs.

Kompressionsfjedre

Compression springs are perhaps the most common type of coil wire spring. They are designed to resist axial loads and are typically wound in a helical shape. When a force is applied to compress the spring, it shortens in length while storing potential energy. Once the force is removed, the spring returns to its original length, releasing the stored energy.These springs are widely used in various applications, including automotive suspensions, mattresses, and industrial machinery. The design of compression springs can vary significantly, with factors such as wire diameter, coil diameter, and the number of active coils influencing their performance. Engineers often select compression springs based on their load requirements and the space available in the application.

Forlængerfjedre

Extension springs, as the name suggests, are designed to operate under tension. Unlike compression springs, which are compressed, extension springs are stretched when a load is applied. They are typically coiled with a gap between the coils, allowing them to elongate when force is applied. Once the force is removed, the spring returns to its original length, similar to compression springs.

These coil wire springs are commonly used in applications where a pulling force is required, such as in garage doors, trampolines, and various machinery. Extension springs are often equipped with hooks or loops at either end to facilitate attachment to other components. The design of extension springs can also vary, with different wire diameters and coil configurations tailored to specific load requirements.

Torsionsfjedre

Torsion springs are unique among coil wire springs as they are designed to work by twisting rather than compressing or extending. These springs store energy when twisted and release it when the force is removed. Torsion springs are typically wound in a helical shape, but their coils are designed to rotate around a central axis.These springs are commonly found in applications such as clothespins, hinges, and various mechanical devices where rotational force is needed. The design of torsion springs is critical, as the amount of torque they can provide depends on factors such as wire diameter, coil diameter, and the number of coils. Engineers must carefully consider these factors to ensure the spring meets the specific requirements of the application.

Coil wire springs play a vital role in countless applications across various industries. Understanding the three primary types—compression springs, extension springs, and torsion springs—allows engineers and designers to select the appropriate spring for their specific needs. Each type of coil spring has unique characteristics and applications, making them indispensable in the world of mechanical design. Whether you are working on a complex machinery project or a simple household item, knowing the differences between these coil springs can help you make informed decisions and ensure optimal performance.

What Are Coil Springs Used For?

Coil springs are an essential component in various mechanical systems, providing flexibility, support, and energy storage. These helical-shaped metal wires are designed to compress and expand, making them ideal for a wide range of applications across different industries. Understanding the uses of coil wire springs can help in appreciating their significance in everyday life and industrial applications.

Automotive Applications

One of the most common uses of coil springs is in the automotive industry. They are integral to the suspension systems of vehicles, where they absorb shocks and vibrations from the road. This function enhances ride comfort and stability, allowing for smoother handling and improved safety. Coil springs are also used in the clutch and brake systems, where they help maintain the necessary tension and ensure proper operation. The durability and resilience of coil wire springs make them suitable for withstanding the rigors of daily driving.

Industrial Machinery

In industrial settings, coil springs play a crucial role in machinery and equipment. They are often used in assembly lines, conveyor systems, and various types of machinery to provide tension and support. For instance, coil springs can be found in presses, where they help maintain pressure on materials being processed. Their ability to store and release energy makes them ideal for applications that require repeated motion or force, such as in pneumatic and hydraulic systems.

Consumer Products

Coil springs are also prevalent in consumer products, enhancing functionality and user experience. Items such as mattresses, office chairs, and even toys often incorporate coil springs to provide comfort and support. In mattresses, for example, coil springs help distribute weight evenly, improving sleep quality. In office chairs, they allow for adjustable seating, providing ergonomic support for users. The versatility of coil wire springs makes them a popular choice in product design, where they can be tailored to meet specific needs.

Aerospace and Defense

In the aerospace and defense sectors, coil springs are used in various applications, including landing gear systems, control surfaces, and safety mechanisms. Their lightweight yet strong construction is ideal for aircraft, where every ounce counts. Coil springs help absorb the impact during landing and provide necessary tension in control systems, ensuring that aircraft operate safely and efficiently. The reliability of coil wire springs in high-stress environments makes them indispensable in these critical industries.

Medical Devices

The medical field also benefits from the use of coil springs. They are found in various medical devices, including surgical instruments, prosthetics, and diagnostic equipment. In prosthetics, coil springs can provide the necessary flexibility and support, mimicking natural movement. In surgical instruments, they help maintain precision and control, ensuring that procedures are performed safely and effectively. The adaptability of coil wire springs allows for innovative designs in medical technology, improving patient outcomes.

Coil wire springs are a fundamental component in numerous applications, ranging from automotive and industrial machinery to consumer products and medical devices. Their ability to absorb shock, provide tension, and store energy makes them invaluable in enhancing performance and functionality. As technology continues to advance, the role of coil springs is likely to expand, leading to new innovations and applications. Understanding what coil springs are used for not only highlights their importance in various industries but also underscores the engineering principles that drive their design and application. Whether in a car, a piece of machinery, or a medical device, coil springs are a testament to the ingenuity of modern engineering.