Indústrias de aplicação

In the construction industry, welded wire mesh grid panels are widely used for building exterior wall insulation, crack prevention, interior partitions, ceilings, floor heating systems, and both interior and exterior wall plastering. In the breeding industry, these wire grid panels serve well in constructing breeding fences, cages, and animal manure leakage boards. The chemical industry utilizes metal grid panels extensively in petrochemical, coal chemical, and fine chemical applications. In agriculture, wire grid walls are commonly used for fencing, greenhouses, and fruit tree enclosures.

Método de fabricação

O processo de fabricação do painel de grade de malha de arame soldado geralmente inclui as seguintes etapas:

- Preparação do fio: Selecione fio de aço com baixo teor de carbono de alta qualidade, endireite-o e corte-o no comprimento necessário.

- Soldagem em grade: Use equipamento de soldagem para soldar o fio em uma estrutura de grade para formar um painel de grade.

- Tratamento de superfície: Realize tratamento de superfície, como galvanoplastia ou galvanização por imersão a quente, no painel da grade conforme necessário para melhorar sua resistência à corrosão e aparência.

- Personalização de tamanho e forma: Corte o painel da grade no tamanho e formato desejados de acordo com as necessidades do cliente.

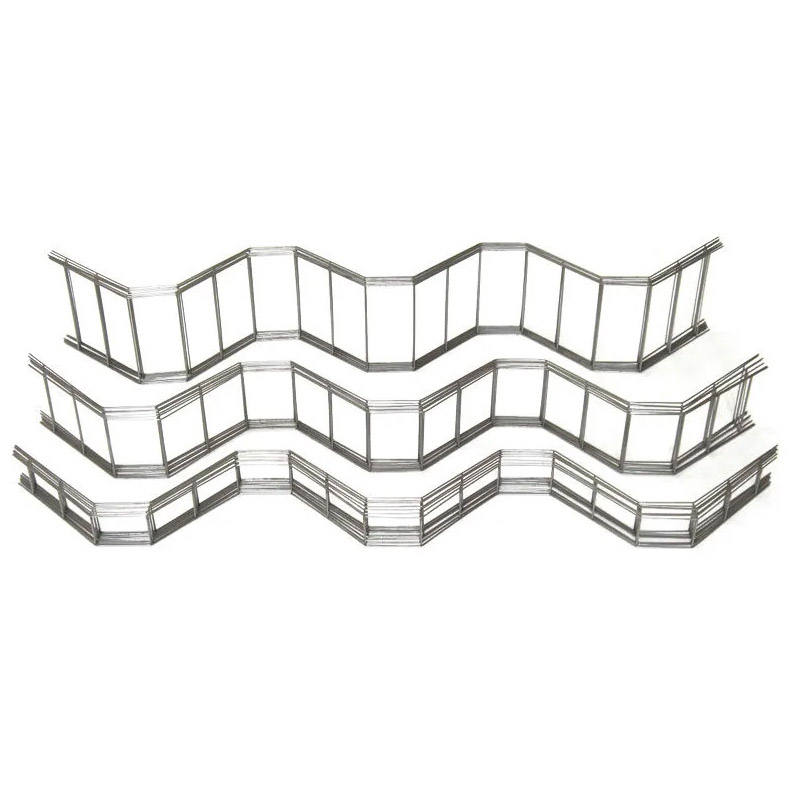

Introdução do produto

As the name suggests, Welded wire mesh Grid panel is a mesh made of high-quality low-carbon steel wire that has been straightened and cut and then welded by electric welding equipment. Welded wire mesh panel is widely used because of its simple structure, fast production, beautiful and practical, and easy to transport.

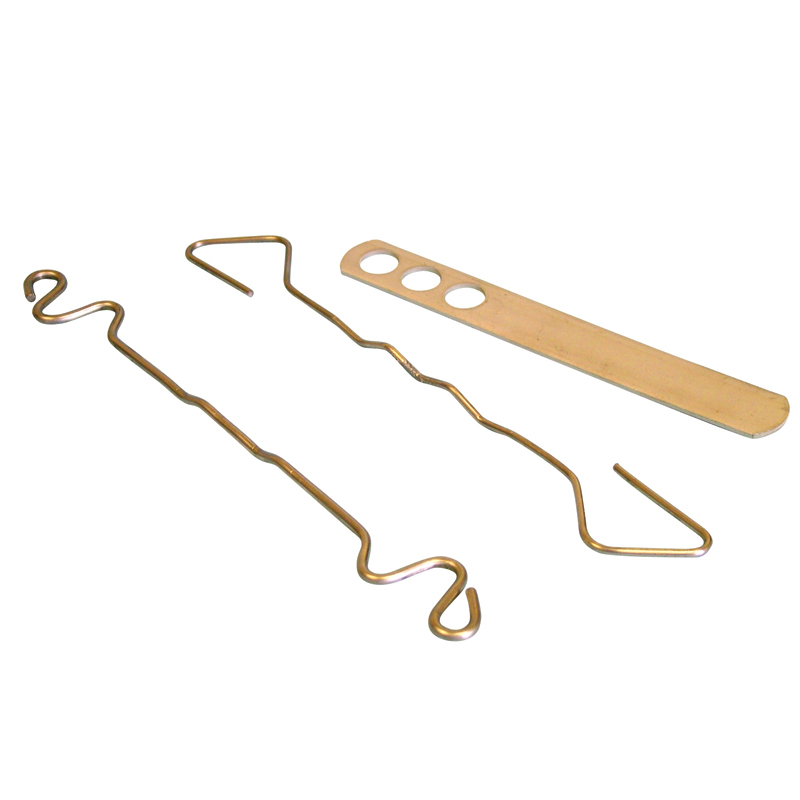

Espaçador de cobra de arame de concreto

|

Specification Of Welded Wire Mesh Panel |

|||

|

Abertura |

Wire diameter |

||

|

Polegada |

milímetros |

BWG |

milímetros |

|

1" × 1" |

25mm x 25mm |

14# - 11# |

2.0mm - 3mm |

|

2" × 1" |

50mm x 25mm |

14# - 8# |

2.0mm - 4mm |

|

2" × 2" |

50mm x 50mm |

14# - 8# |

2.0mm - 4mm |

|

3" × 2" |

75mm x 50mm |

14# - 6# |

2.0mm - 5mm |

|

3" × 3" |

75mm x 75mm |

14# - 6# |

2.0mm - 5mm |

|

4" × 2" |

100mm x 50mm |

14# - 4# |

2.0mm - 6mm |

|

4" × 4" |

100mm x 100mm |

14# - 4# |

2.0mm - 6mm |

|

5" × 5" |

125 mm x 125 mm |

14# - 4# |

2.0mm - 6mm |

|

6" × 6" |

150 mm x 150 mm |

14# - 4# |

2.0mm - 6mm |

|

Material: Low carbon steel wire |

|||

|

Surface treatment: Electro Galvanized, Hot dipped galvanized, PVC coated, Powder revestido |

|||

|

Observação: Special size and specifications can be made according to customers requires. |

|||

We can do any size and shape wire mesh grids panel according clients’ need .

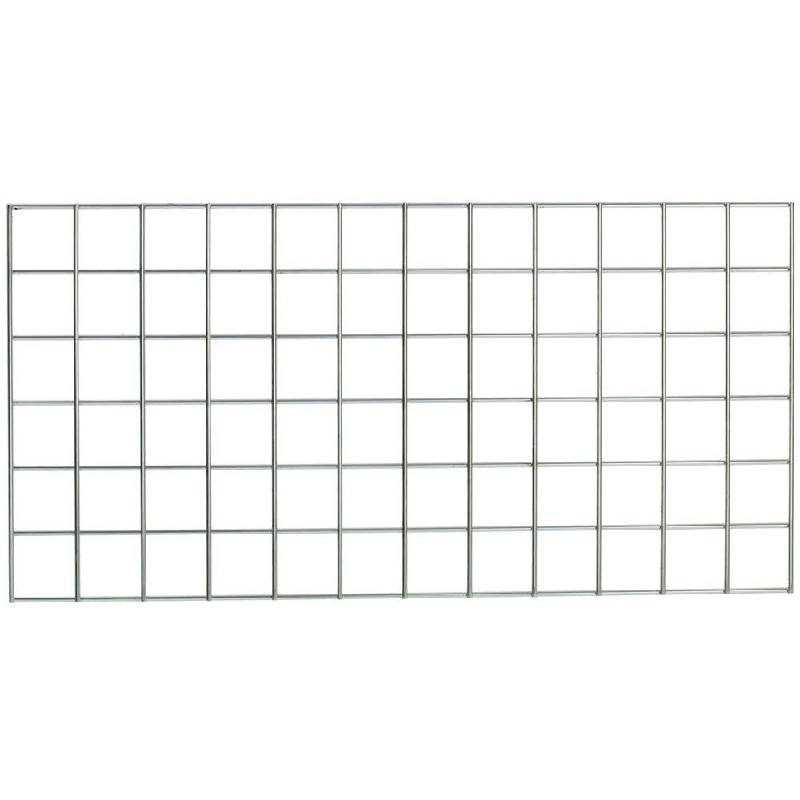

What Is the Use of a Grid Wall?

A grid wall isn’t just a decorative piece—it’s a highly functional and versatile display system widely used across retail, exhibition, and interior organization settings. At Shijiazhuang TangChao Metal Products Co., Ltd., we manufacture durable, high-quality metal grid wall solutions that meet global standards, supporting clients from boutique shops in Japan to exhibitions in the UAE.

Retail Display Efficiency:

In retail environments, wire grid walls are often used to showcase merchandise such as apparel, accessories, tools, or electronics. With the right grid wall accessories, retailers can easily reconfigure their layouts using hooks, shelves, and baskets. The modularity allows quick seasonal updates without the cost of permanent fixtures. For clothing stores, a grid wall clothing display can hold hangers or racks, making it a clean and modern way to organize garments by size, style, or brand.

Storage and Home Organization:

Consumers increasingly use wire grid display panels at home, turning walls into stylish organizers for kitchens, craft rooms, or study spaces. Paired with clips and shelves, a large wire wall grid can hold tools, photos, or stationery—making it popular among DIY enthusiasts and home decorators. Some even convert a wire wall grid photo display into a mood board or vision wall.

Event and Exhibition Displays:

For trade shows, grid wall panels serve as lightweight, portable walls that hold marketing materials, samples, or products. Their durability—especially when made with precision from galvanized steel—ensures reliable support for repeated setups and disassemblies.

As a company established in 1998 with over two decades of experience, TangChao Metal exports to more than 15 countries and regions. Our wire grids for sale are produced using German- and Korean-imported equipment, ensuring excellent structural integrity and smooth finishes. Whether for retail, home, or commercial display, our metal grid walls are engineered for both form and function.

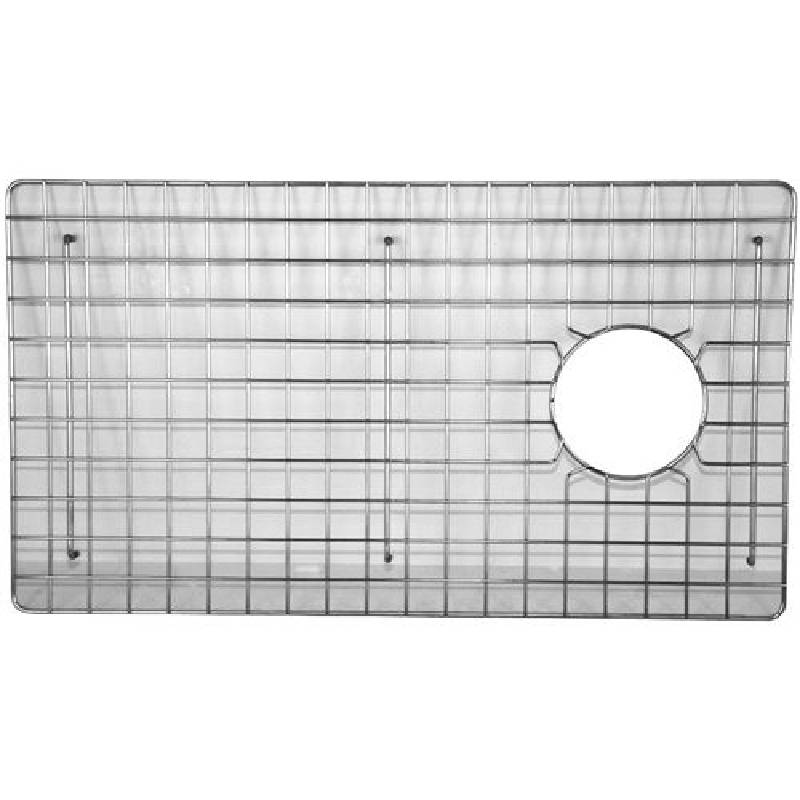

How to Make a Wire Grid Panel?

Creating a wire grid panel might seem simple, but achieving strength, consistency, and finish requires precise engineering and expert manufacturing processes. At Shijiazhuang TangChao Metal Products Co., Ltd., each panel undergoes a rigorous production cycle rooted in years of metalwork experience and enhanced by world-class machinery.

Step 1: Selecting the Material

The foundation of every wire grid wall panel begins with premium low-carbon steel wire. This material offers an optimal balance between flexibility and strength. Our factory sources only cost-effective, high-quality raw steel, ensuring the final metal wire grid is durable and corrosion-resistant.

Step 2: Precision Welding and Cutting

Using advanced machines imported from Germany and Korea, wires are fed into automated welding systems that fuse them at consistent intervals. The grid mesh spacing—whether for standard display or heavy duty metal grid panel use—is precisely set according to customer specifications. After welding, panels are trimmed to size with minimal tolerances.

Step 3: Surface Treatment

Surface finishing options vary based on intended application. Popular choices include powder coating in black or white, or hot-dip galvanizing for rust protection. Our black wire grid wall panel is especially favored in retail for its sleek, modern look, while galvanized options are preferred in outdoor or high-humidity environments.

Step 4: Quality Control and Packaging

Each wire wall grid panel is inspected for weld consistency, coating adhesion, and structural integrity. Our quality control team—part of a workforce including 30 technical experts—ensures every product meets international export standards before packaging and shipment.

Thanks to a 7,000-square-meter facility and an annual output of 22 million RMB, TangChao Metal maintains steady supply to markets like Europe, Australia, and North America. Whether you're a store owner, distributor, or designer looking for gridwall panels for sale, we offer tailored solutions that combine aesthetic flexibility with industrial-grade quality.