Application industries

In the construction industry, Welded wire mesh Grid panel is often used in building exterior wall insulation, building crack prevention, interior partition, ceiling ceiling, floor heating, interior and exterior wall plastering, etc. In the breeding industry, Welded wire mesh Grid panel is often used in breeding fences, breeding cages, breeding animal manure leakage boards, etc. In the chemical industry, Welded wire mesh Grid panel is often used in the petrochemical industry, coal chemical industry, fine chemical industry, etc. In the agricultural industry, Welded wire mesh Grid panel is often used in agricultural fences, agricultural greenhouses, agricultural greenhouses, fruit tree fences, etc.

Manufacturing method

The manufacturing process of Welded wire mesh Grid panel usually includes the following steps:

- Wire preparation: Select high-quality low-carbon steel wire and straighten and cut it to the required length.

- Grid welding: Use welding equipment to weld the wire into a grid structure to form a grid panel.

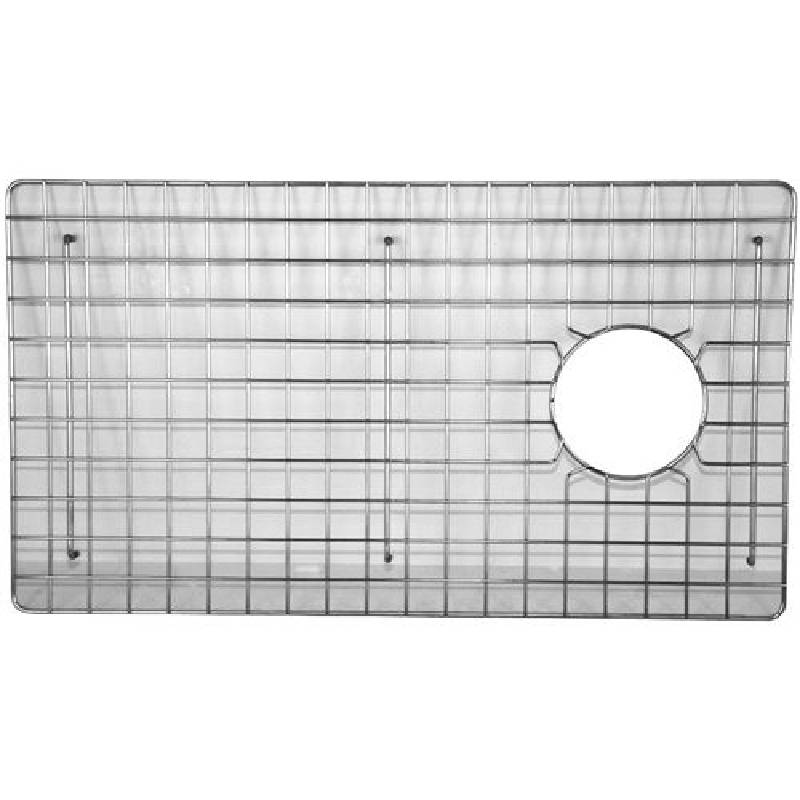

- Surface treatment: Carry out surface treatment, such as electroplating or hot-dipping galvanizing, on the grid panel as needed to improve its corrosion resistance and appearance.

- Size and shape customization: Cut the grid panel into the required size and shape according to customer needs.

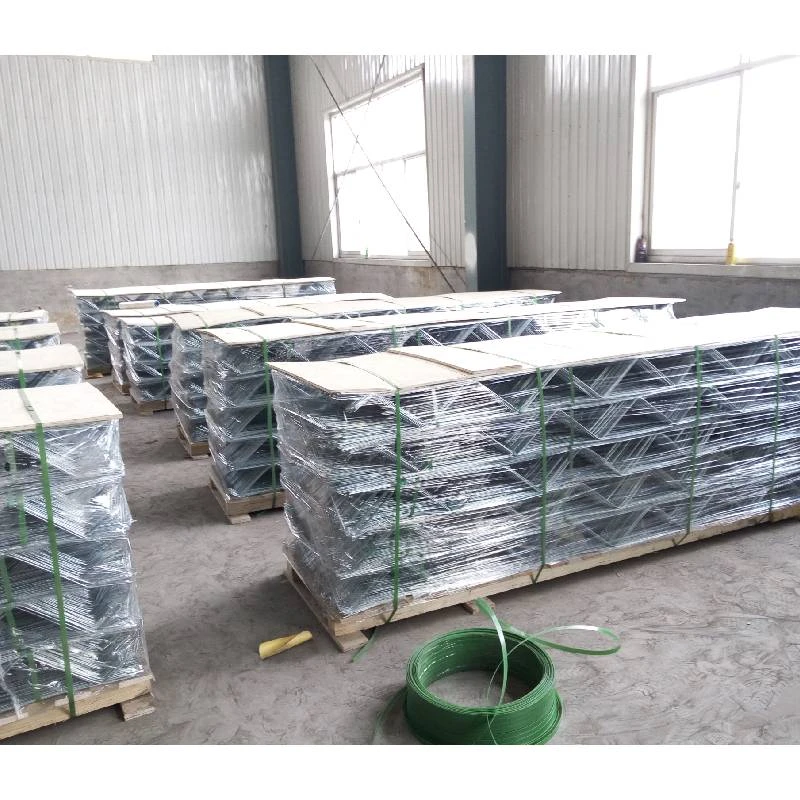

Product Introduction

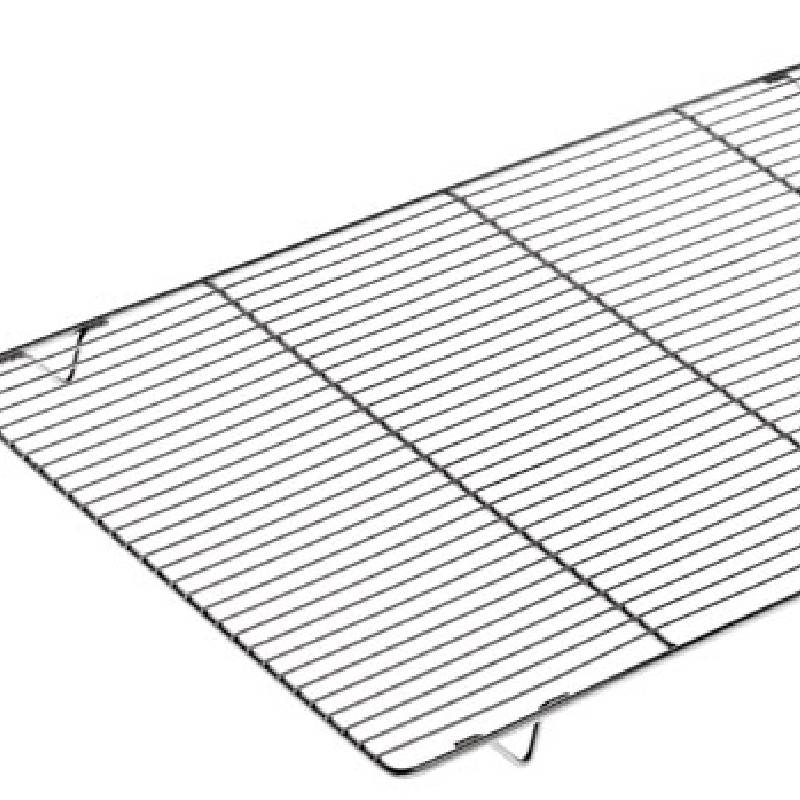

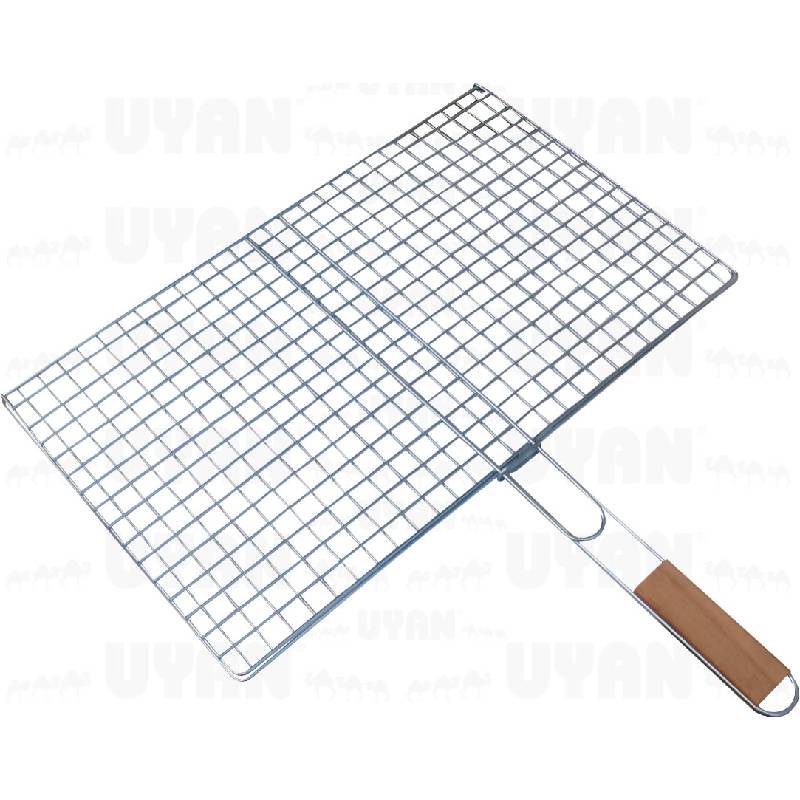

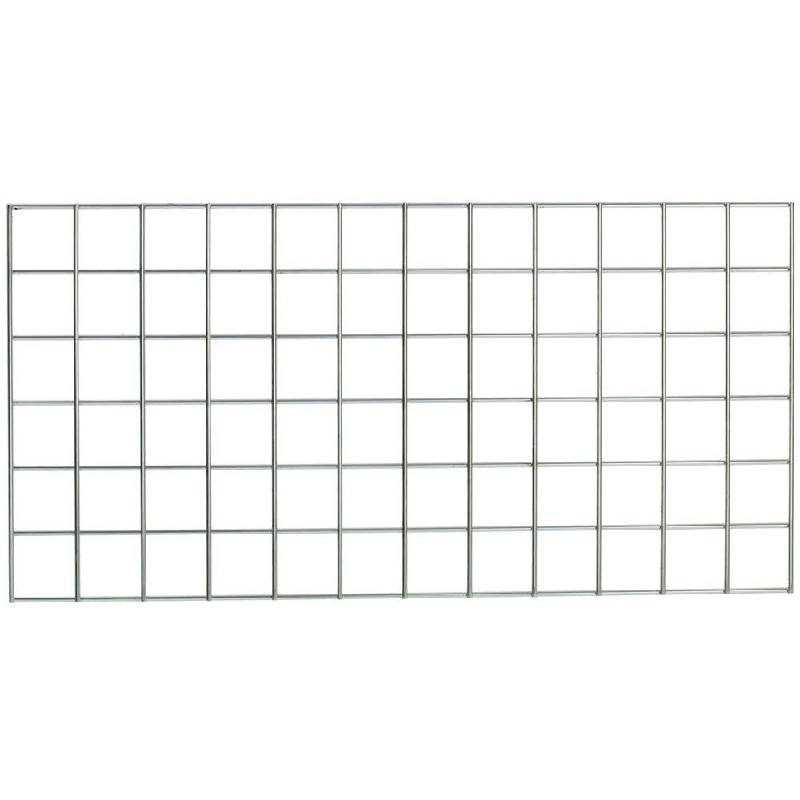

As the name suggests, Welded wire mesh Grid panel is a mesh made of high-quality low-carbon steel wire that has been straightened and cut and then welded by electric welding equipment. Welded wire mesh panel is widely used because of its simple structure, fast production, beautiful and practical, and easy to transport.

Concrete wire snake spacer

|

Specification Of Welded Wire Mesh Panel |

|||

|

Opening |

Wire diameter |

||

|

Inch |

mm |

BWG |

mm |

|

1" × 1" |

25mmx25mm |

14# - 11# |

2.0mm - 3mm |

|

2" × 1" |

50mmx25mm |

14# - 8# |

2.0mm - 4mm |

|

2" × 2" |

50mmx50mm |

14# - 8# |

2.0mm - 4mm |

|

3" × 2" |

75mmx50mm |

14# - 6# |

2.0mm - 5mm |

|

3" × 3" |

75mmx75mm |

14# - 6# |

2.0mm - 5mm |

|

4" × 2" |

100mmx50mm |

14# - 4# |

2.0mm - 6mm |

|

4" × 4" |

100mmx100mm |

14# - 4# |

2.0mm - 6mm |

|

5" × 5" |

125mmx125mm |

14# - 4# |

2.0mm - 6mm |

|

6" × 6" |

150mmx150mm |

14# - 4# |

2.0mm - 6mm |

|

Material: Low carbon steel wire |

|||

|

Surface treatment: Electro Galvanized, Hot dipped galvanized, PVC coated, Powder coated |

|||

|

Note: Special size and specifications can be made according to customers requires. |

|||

We can do any size and shape wire mesh grids panel according clients’ need .