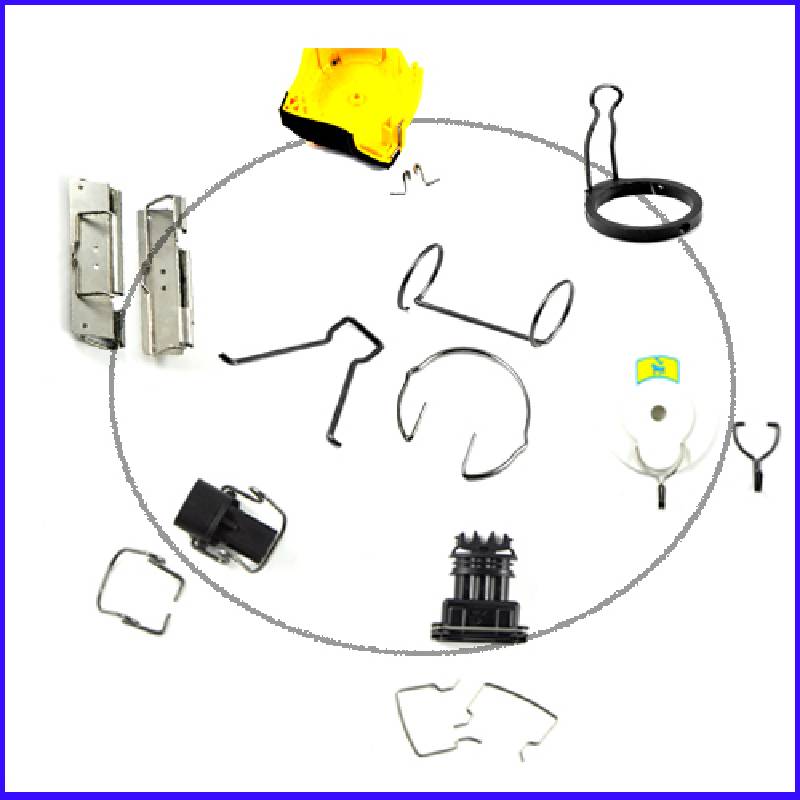

Selection of steel wire

Select the appropriate steel wire according to the specific application and performance requirements.

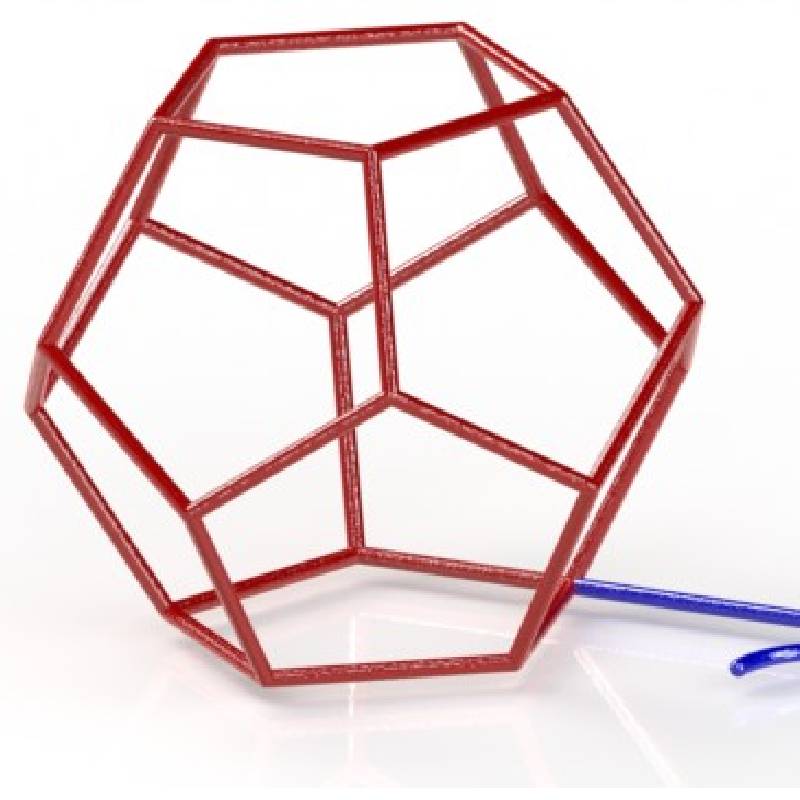

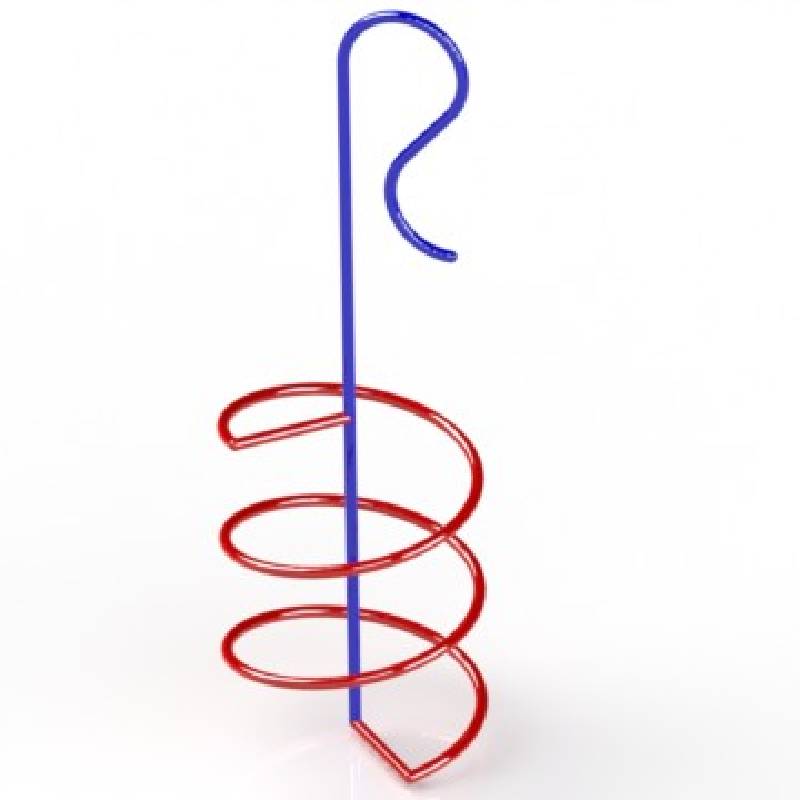

- Design and preparation: Design and prepare the forming dies or tools required for the desired shape and size of the steel wire components.

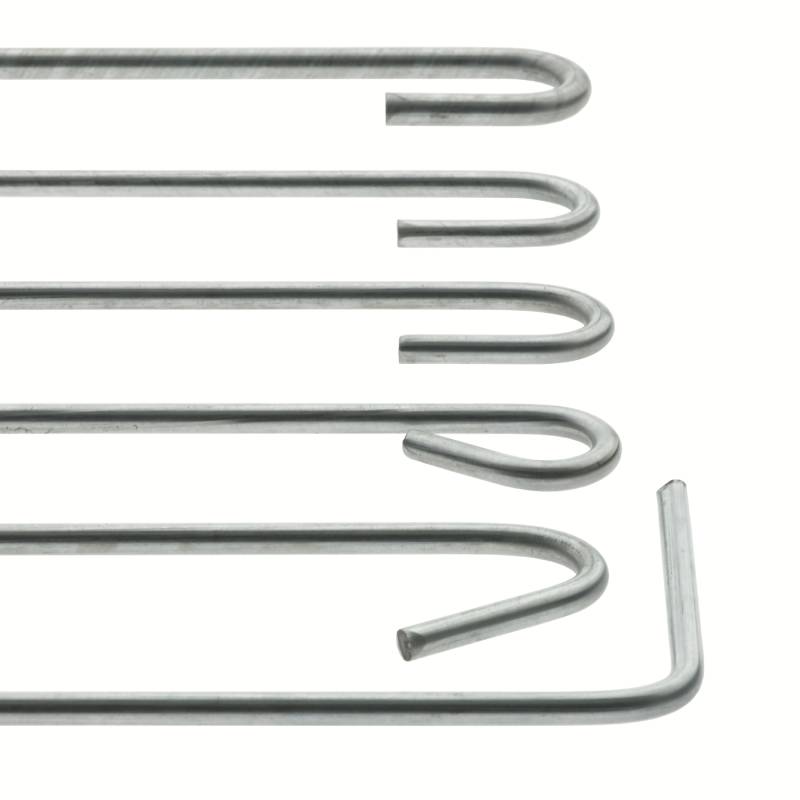

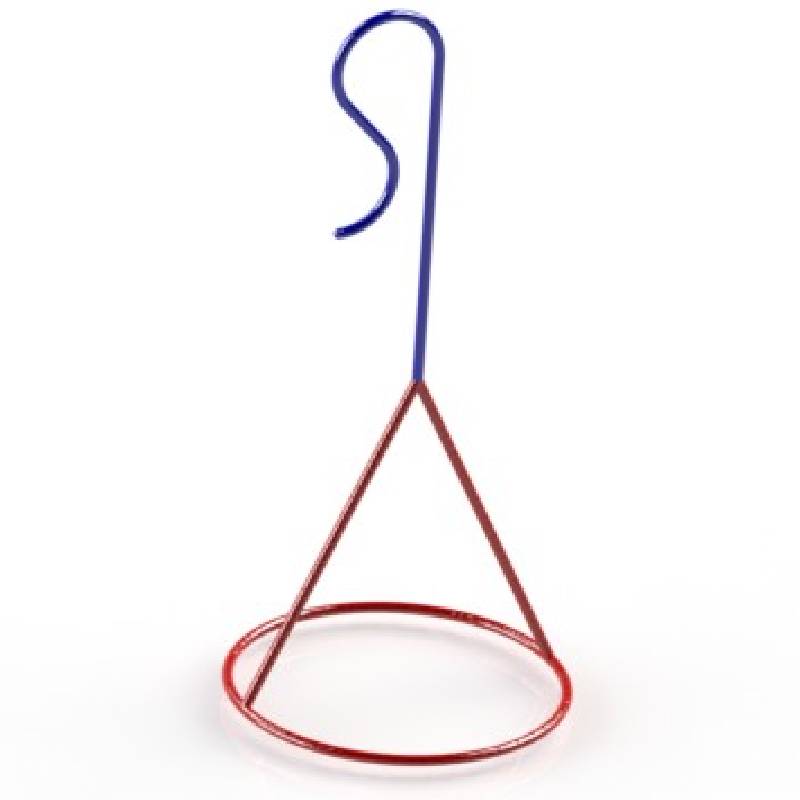

- Forming process: Bend and shape the steel wire into the desired shape using the forming dies or tools, and cut or grind it to the required length and size.

- Surface treatment: Perform surface treatment on the formed steel wire as needed to improve its appearance, corrosion resistance, and fatigue resistance.

- Assembly and installation: Assemble and install the formed steel wire components in the target product or device.

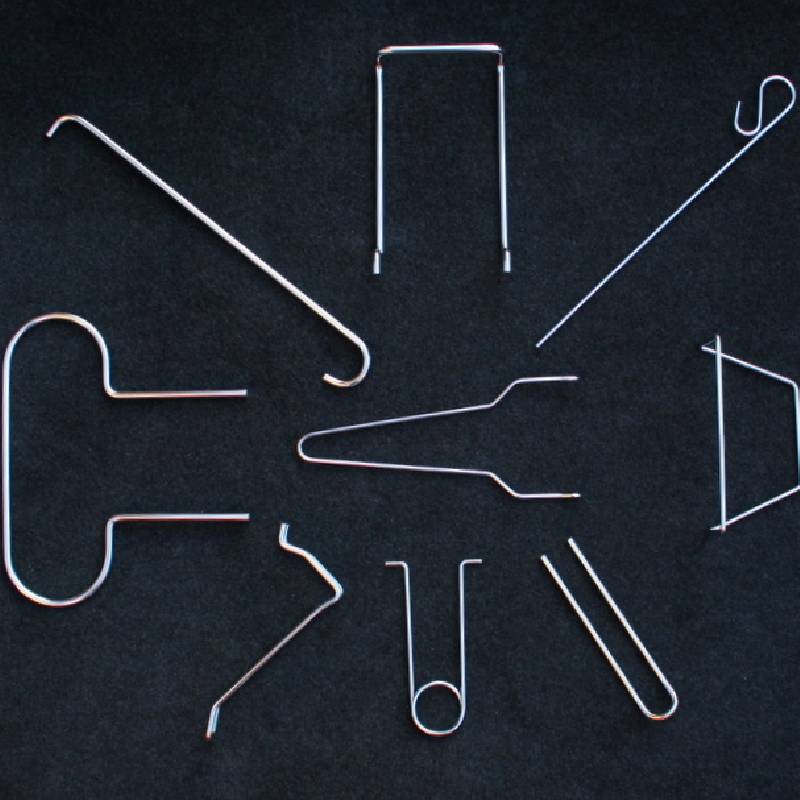

Our company can produce any size, shape, and material customised products according to customer requirements. Our experienced engineers and technicians can produce customised steel wire components according to customer drawings and requirements. If you have any specific requirements or questions about Steel Wire Forming, please feel free to contact us, and we will do our best to meet your needs.

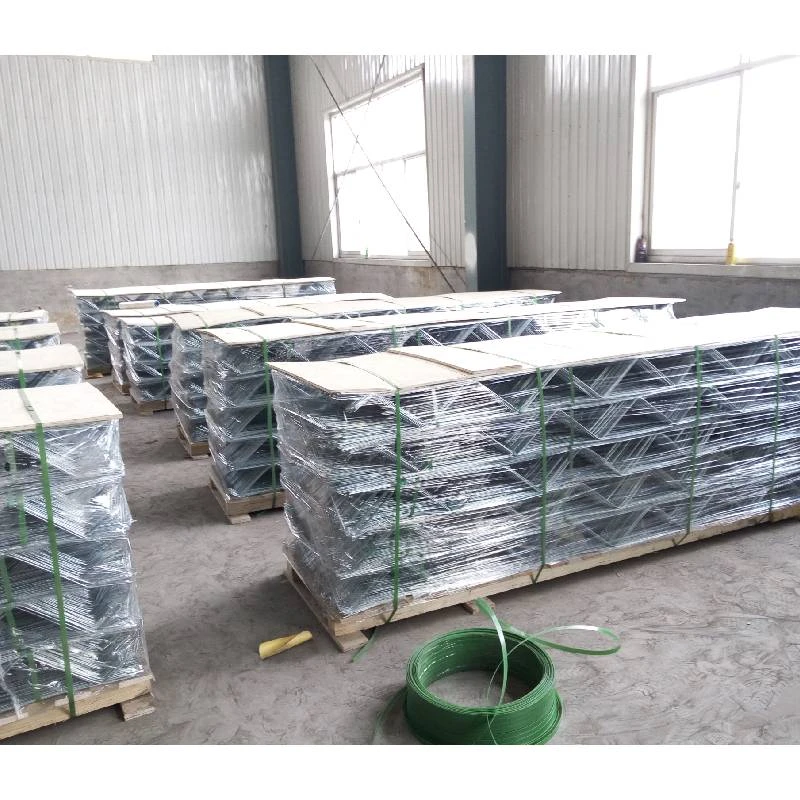

Packaging & Delivery

Packaging: DetailsInner packing--PE bag, Outer---Standard Carton Box , Custom Stainless Steel Wire Forming Parts

Delivery Time:usually 7-15 days, Custom Stainless Steel Wire Forming Partsspecification of Wire Forming Parts, Wire Bending Parts。available upon request。

Specification

|

Item name |

Stainless Steel Wire Forming Parts, Wire Bending Parts |

|

Material |

Carbon steel, stainless steel, spring steel, brass, bronze and cooper are available |

|

Dimension |

different size as customer required |

|

Surface treatment |

Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, and imitation gold-plated are ok for choice |

|

Application |

Different kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

|

Equipment |

Advanced CNC spring machinery imported from Japan, Germany and Taiwan; Advanced grinding and shot peening machinery; Precise tensile strength testers, compression testers, endurance testers, and magnetic powder flaw detectors |

|

Packing |

Inner---PE Bag; Outer --Standard Carton Box |

|

Payment term |

T/T , western union , L/C |

|

Delivery & Shipping |

We can offer products on time, usually 7days after order, shipping by DHL, Fedex, TNT,,UPS |

|

Service |

Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |