Descrição detalhada

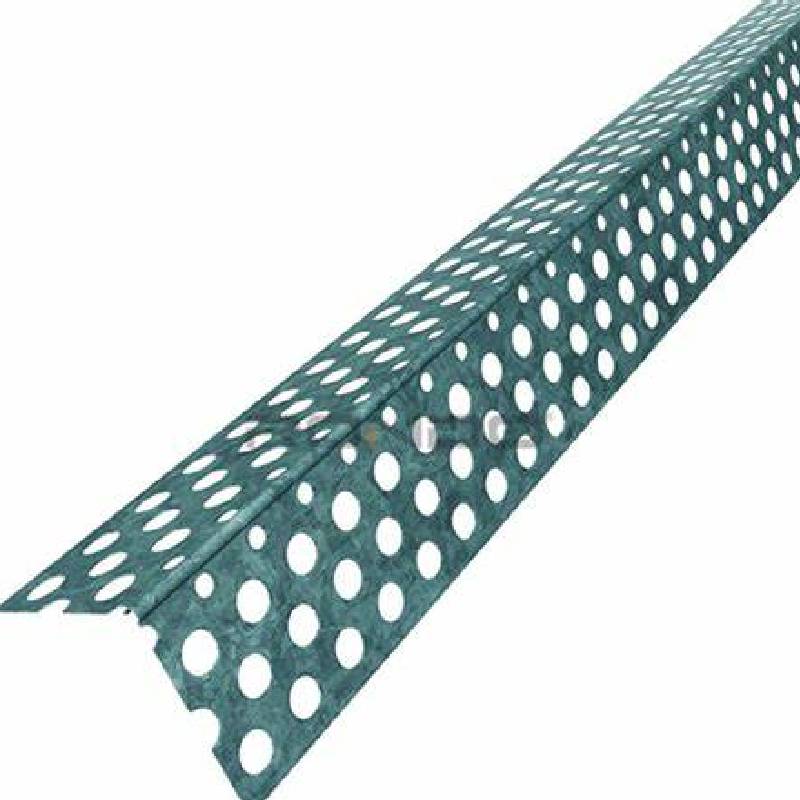

O cordão angular de gesso perfurado é um cordão angular de metal com perfurações, feito de chapa galvanizada. O seu design perfurado permite a passagem da lama, para que possa ser combinada com a parede. Esta conta angular pode ter diferentes comprimentos de asa, geralmente entre 1,8 cm e 3 cm, para atender a diferentes necessidades. Além disso, também pode fornecer uma variedade de opções de comprimento para reduzir o desperdício e minimizar as costuras. O desenho perfurado do cordão angular ajuda a melhorar a aderência da lama, tornando a parede mais plana e bonita.

Introdução do produto

Conta angular perfurada de gesso galvanizado , Conta angular perfurada de gesso é feita de placa galvanizada. Podemos produzir a asa de 1,8 cm a 3 cm. O intrincado padrão de furos permite que a lama penetre através do cordão até a parede de gesso. A conta passa a fazer parte da parede. Fácil de usar. Basta fixar na parede de gesso e você estará pronto para enlamear. O cordão de canto perfurado se adapta às irregularidades do enquadramento e se adapta às alturas apropriadas da mesa. Fornecido em aço galvanizado, alumínio, aço inoxidável.

Indústrias de aplicação

O cordão angular de gesso perfurado é usado principalmente na indústria da construção, especialmente para decoração e proteção de paredes e tetos internos. É frequentemente usado em edifícios residenciais, comerciais e industriais para fornecer linhas de canto planas e bonitas, ao mesmo tempo que protege os cantos contra danos. Além disso, também pode ser utilizado para decoração de interiores em locais como hospitais, escolas e hotéis para proporcionar um ambiente saudável e bonito.

Descrição detalhada do produto

|

Asa:: |

20-30 mm |

Comprimento: |

2-3m |

|

Material: |

Aço galvanizado, alumínio, aço inoxidável. |

Embalagem: |

50 unidades/caixa 100 unidades/caixa |

|

Nome: |

Conta de canto perfurada |

Tipo de furo: |

Redondo, Retangular |

|

Destaque: |

Conta angular de metal de asa de 2 cm , conta angular de metal em chapa galvanizada , cantoneira de gesso perfurada 3m |

||

Norma

Material: chapa galvanizada, chapa de aço inoxidável, chapa de alumínio etc.

Espessura da placa: 0,3-0,5 mm

Comprimento: Padrão 2,4m-3m, também de acordo com a necessidade do cliente.

Tamanho do furo: borda de 5 × 15 mm, 10 × 20 mm, 10 × 30 mm

Largura: 18mm*18mm,20mm*20mm 30 × 30mm,

Tamanho

|

Grossura |

asa |

Comprimento |

|

0,2-0,4mm |

18mm-30mm |

2-3 |

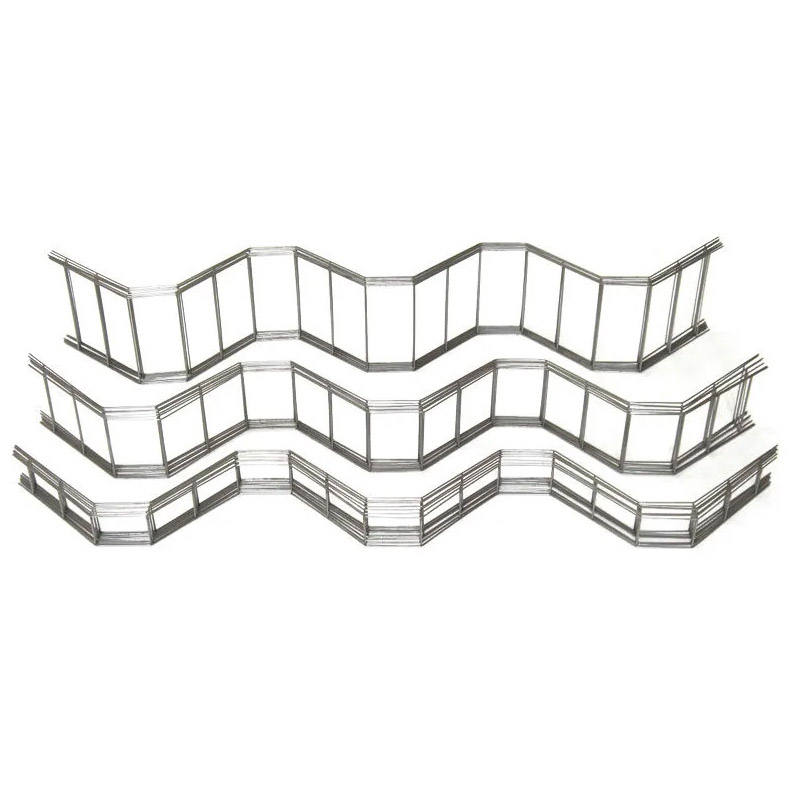

Understanding Hy Rib Mesh Size

When considering hy rib mesh size for plastering metal corner bead applications, it's important to choose the right dimensions to ensure proper installation and durability. At Shijiazhuang TangChao Metal Products Co., Ltd., we produce high-quality plastering metal corner beads using advanced manufacturing techniques, which are ideal for both residential and commercial projects. With our rich history since 1998, we have honed the expertise to offer the best materials for your plastering needs, combining strength and precision.

Hy rib mesh size plays a crucial role in achieving a flawless plaster finish. Here’s a breakdown of the key aspects:

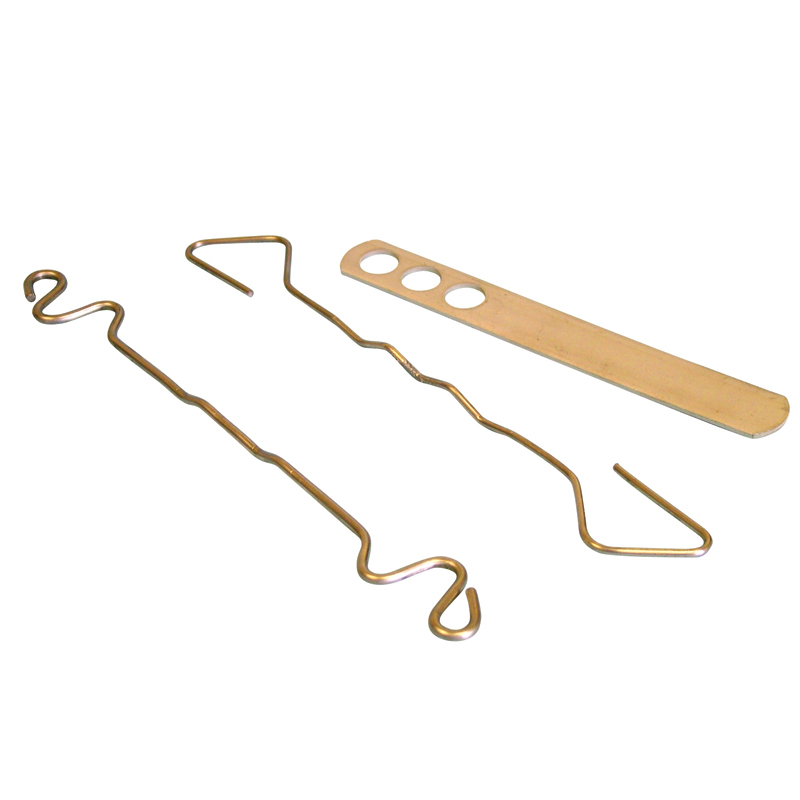

1.Mesh Thickness and Strength: The hy rib mesh sheet typically features a robust thickness that offers excellent support for plaster, preventing cracks and ensuring a long-lasting finish. Whether you're using it for external or internal corner bead applications, the strength of the mesh helps maintain the structural integrity of plastered walls.

2.Mesh Spacing: The distance between the ribs in the hy rib mesh influences the plaster's adherence. For thicker coatings, larger spacing may be preferred, while finer meshes provide smoother and more precise finishes for thin layers of plaster.

3.Custom Sizes: At TangChao Metal, we understand that not all projects are the same. That’s why we offer a variety of hy rib mesh sizes tailored to suit different types of plastering applications. Whether you're working on large commercial buildings or smaller residential projects, our mesh ensures efficient installation and optimal performance.

4.Compatibility with Other Beads: The galvanized plaster angle bead and other types of plaster beads we manufacture are designed to work seamlessly with hy rib mesh, ensuring smooth transitions at corners and edges. The integration of mesh and beads guarantees that your plastering job is both secure and aesthetically pleasing.

Choosing the right hy rib mesh size is essential for achieving a durable and smooth plaster finish. By combining high-quality materials like our plastering metal corner beads and reliable mesh, you ensure the longevity and stability of your plastered surfaces.

How to Install Hy Rib Mesh?

Hy rib mesh installation is a critical step in plastering projects, ensuring a solid foundation for your plaster or render to adhere to. At Shijiazhuang TangChao Metal Products Co., Ltd., we provide comprehensive solutions for plastering metal corner beads, ensuring that each element of your project, from mesh to bead, integrates seamlessly for a high-quality finish. With our advanced equipment and years of experience, we help you achieve efficient installation with minimal hassle.

Here’s a step-by-step guide on how to install hy rib mesh:

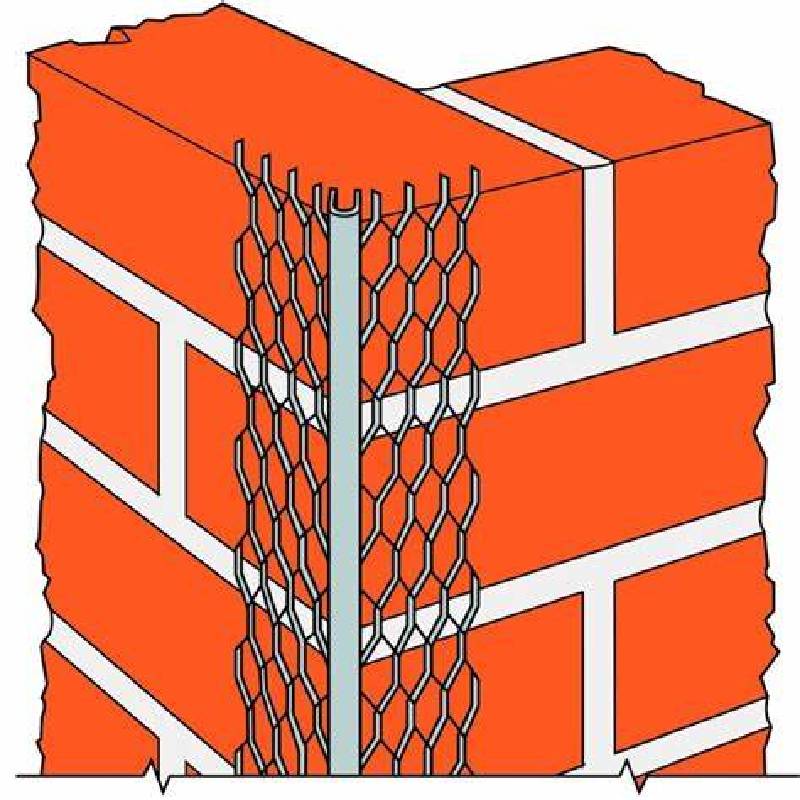

1.Preparation of Surfaces: Before installing the hy rib mesh, ensure that the surfaces are clean and free from debris. Proper surface preparation ensures better adhesion of plaster to the mesh.

2.Cutting the Mesh to Size: Depending on the dimensions of the area to be plastered, the hy rib mesh can be cut to the required size using simple tools. Make sure to leave enough overlap at the joints to maintain a strong connection between sections.

3.Positioning the Mesh: Once cut, the hy rib mesh sheet is laid onto the surface, aligning the ribs parallel to the corners or edges. For external corners, ensure the mesh fits snugly against the corner bead to create a smooth, crisp finish.

4.Fixing the Mesh: Secure the mesh in place using staples or nails, ensuring it is taut and firmly attached to the underlying structure. For large surfaces, consider using our galvanized render beads to further support the mesh, giving your plaster a solid backing.

5.Plaster Application: With the hy rib mesh firmly in place, apply the plaster or render in even layers, allowing it to cure thoroughly. The mesh acts as a reinforcement, preventing cracks and ensuring the longevity of the plastered finish.

6.Finishing Touches: After the plaster has set, smooth the surface using a plastering trowel. The plastering metal corner bead will give the corners a sharp, clean edge, ensuring a professional look.

By following these steps and using our high-quality hy rib mesh, you can achieve a flawless plastering finish. Our mesh is designed to be easy to install while providing robust reinforcement for plaster surfaces, making it the ideal choice for both new builds and renovation projects.

Proper hy rib mesh installation is key to achieving a durable and smooth plaster finish. With TangChao Metal’s comprehensive products, you are guaranteed a seamless plastering experience.