Wire Mesh

What Is Wire Mesh Used For?

Wire mesh, a versatile and durable material, has become an essential component in various industries and applications. Composed of interconnected wires that are woven or welded together, wire mesh is available in different materials, including stainless steel, aluminum, and galvanized steel. Its unique properties make it suitable for a wide range of uses, from construction to agriculture, and even in artistic endeavors. In this article, we will explore the various applications of wire mesh and its significance in modern society.

Construction and Building

One of the primary uses of wire mesh is in the construction industry. It serves as a reinforcement material in concrete structures, providing added strength and stability. When embedded in concrete, wire mesh helps to distribute loads evenly, reducing the risk of cracking and structural failure. This application is particularly important in the construction of roads, bridges, and buildings, where durability is paramount.

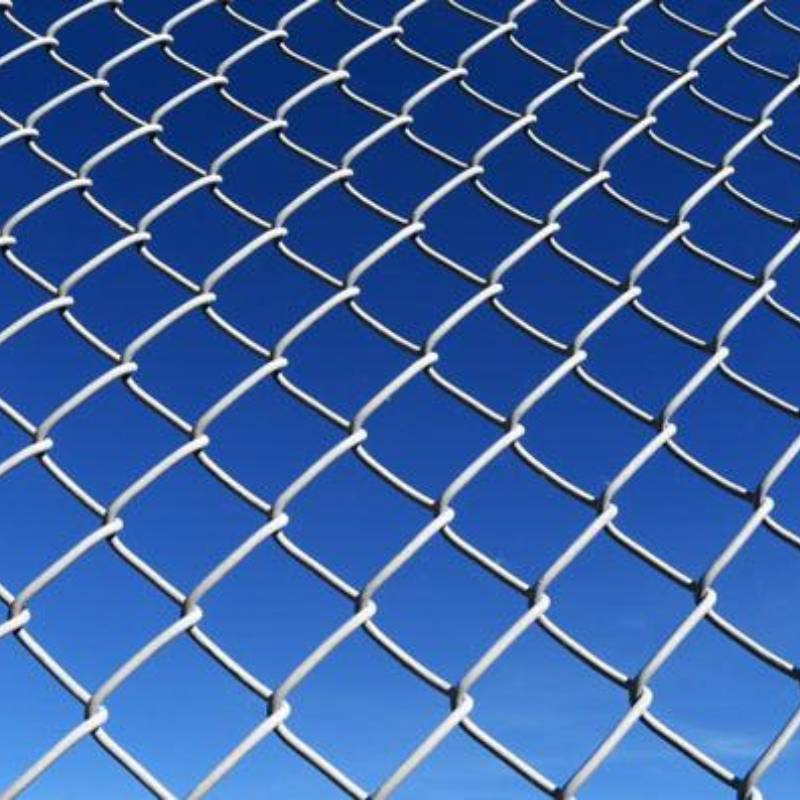

Additionally, wire mesh is often used in fencing applications. It provides a secure barrier for residential and commercial properties, keeping unwanted animals and intruders at bay. Chain-link fencing, made from wire mesh, is a popular choice for its affordability and effectiveness in enclosing large areas, such as sports fields, parks, and industrial sites.

Agriculture and Horticulture

In the agricultural sector, wire mesh plays a crucial role in protecting crops and livestock. It is commonly used to create enclosures for animals, preventing them from wandering off and protecting them from predators. Wire mesh fencing is also employed to safeguard gardens and orchards from pests, ensuring that crops can grow without interference.

Moreover, wire mesh is utilized in the construction of trellises and supports for climbing plants. By providing a sturdy framework, wire mesh allows plants to grow vertically, maximizing space and improving air circulation. This application is particularly beneficial in urban gardening and small-scale farming, where space is often limited.

Industrial Applications

Wire mesh is widely used in various industrial applications due to its strength and versatility. It is commonly found in filtration systems, where it acts as a barrier to separate solids from liquids or gases. This is particularly important in industries such as food processing, pharmaceuticals, and chemical manufacturing, where maintaining product purity is essential.

In addition, wire mesh is used in the production of safety equipment, such as guards and screens for machinery. These protective barriers help prevent accidents by keeping workers safe from moving parts and hazardous materials. Wire mesh is also employed in the construction of storage containers and pallets, providing a lightweight yet sturdy solution for transporting goods.

Artistic and Decorative Uses

Beyond its practical applications, wire mesh has also found a place in the world of art and design. Artists and designers often use wire mesh to create sculptures, installations, and decorative elements. Its malleability allows for intricate designs, while its transparency adds a unique visual dimension to artworks.

In interior design, wire mesh can be used as a stylish partition or as part of furniture design, offering a modern aesthetic while maintaining functionality. Its ability to blend with various materials makes it a popular choice for contemporary spaces.

Wire mesh is a multifaceted material with a wide array of applications across different industries. From construction and agriculture to industrial uses and artistic endeavors, its strength, durability, and versatility make it an invaluable resource. As technology continues to advance, the potential uses for wire mesh are likely to expand, further solidifying its role in modern society. Whether you are a builder, farmer, industrial worker, or artist, wire mesh is a material that can enhance your projects and improve efficiency.

What Wire Mesh To Use In Concrete?

When it comes to reinforcing concrete structures, wire mesh plays a crucial role in enhancing the strength and durability of the final product. Understanding the different types of wire mesh available and their specific applications can help you make informed decisions for your construction projects. This article will explore the various types of wire mesh and provide guidance on what wire mesh to use in concrete.

Understanding Wire Mesh

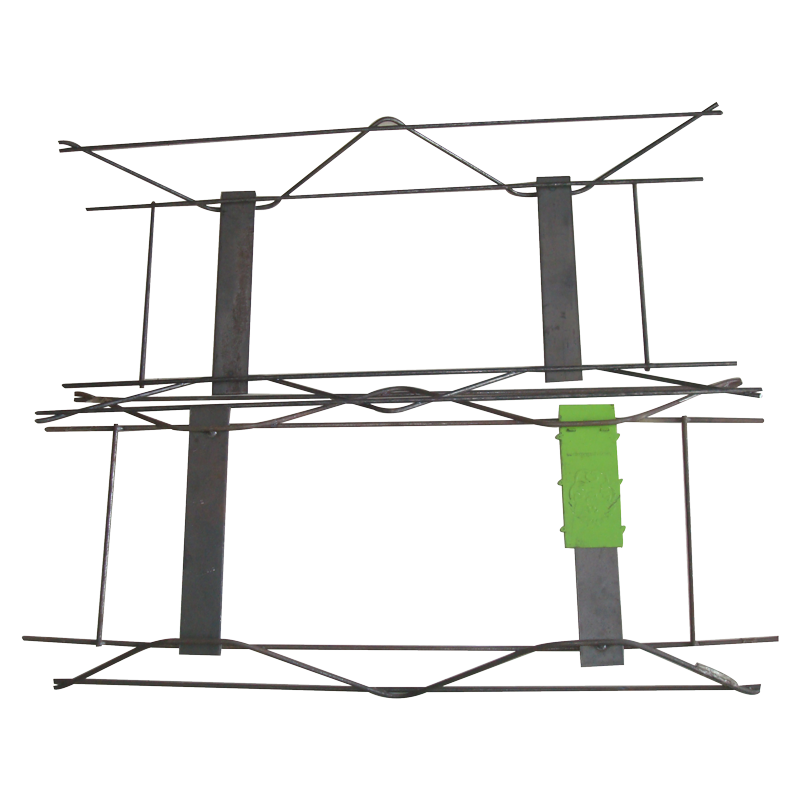

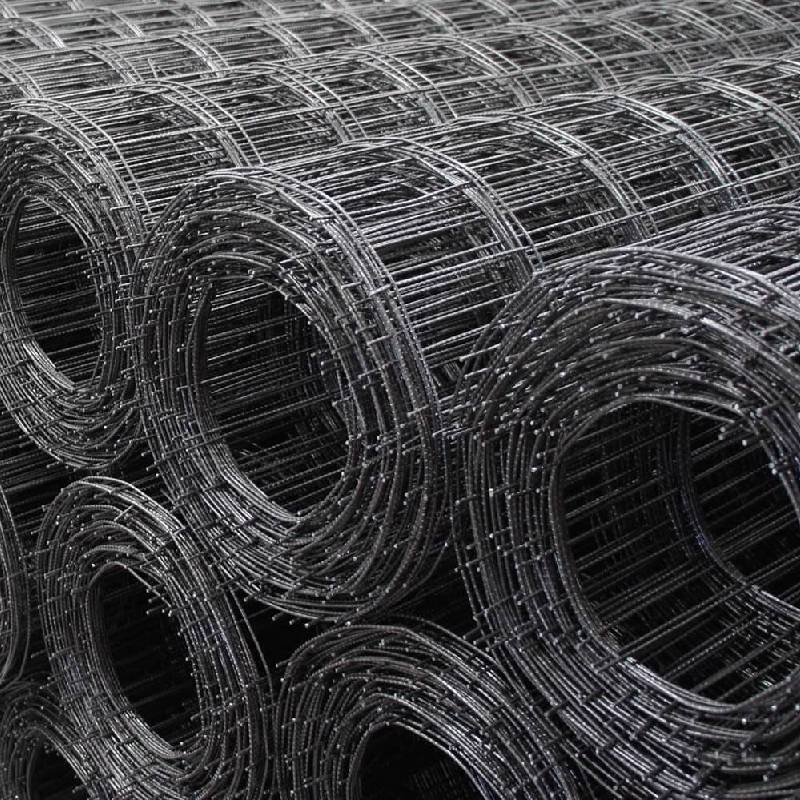

Wire mesh, also known as welded wire fabric (WWF), is a grid-like structure made from steel wires that are welded together at regular intervals. It is commonly used in construction to provide tensile strength and prevent cracking in concrete slabs, walls, and other structures. The mesh is available in various sizes, gauges, and configurations, making it adaptable to different construction needs.

Types of Wire Mesh

Welded Wire Fabric (WWF): This is the most common type of wire mesh used in concrete applications. It consists of longitudinal and transverse wires that are welded together at intersections. WWF is available in various sizes, typically measured in inches, and is categorized by the spacing of the wires and the gauge of the steel. The most common sizes for concrete reinforcement are 4x4 inches and 6x6 inches, with wire gauges ranging from 10 to 16.

Reinforcing Wire Mesh: This type of wire mesh is specifically designed for reinforcing concrete slabs and pavements. It is often used in driveways, sidewalks, and floors to provide additional support and prevent cracking. Reinforcing wire mesh is typically heavier and has a closer spacing than standard WWF, making it ideal for high-load applications.

Fiberglass Wire Mesh: While not made of steel, fiberglass wire mesh is another option for reinforcing concrete. It is lightweight, resistant to corrosion, and can be used in applications where steel mesh may not be suitable. Fiberglass mesh is often used in thin concrete overlays and decorative concrete applications.

When deciding what wire mesh to use in concrete, consider the following factors:

Load Requirements: Assess the load that the concrete structure will bear. For heavy loads, such as in industrial applications, a heavier gauge wire mesh with closer spacing may be necessary to provide adequate support.

Type of Concrete: The type of concrete being used can also influence your choice of wire mesh. For example, if you are working with a thin slab or overlay, a lighter mesh may suffice, while thicker slabs may require more robust reinforcement.

Environmental Conditions: Consider the environmental conditions where the concrete will be placed. If the area is prone to moisture or chemical exposure, opting for galvanized or stainless steel wire mesh can help prevent corrosion and extend the lifespan of the structure.

Installation Method: The installation method can also dictate the type of wire mesh you choose. For instance, if you are pouring concrete in a slab form, welded wire fabric can be laid flat and easily integrated into the mix. In contrast, if you are working with precast concrete elements, you may need to use a different type of mesh that can be easily incorporated into the manufacturing process.

Wire mesh is an essential component in reinforcing concrete structures, providing strength and stability. By understanding the different types of wire mesh available and considering factors such as load requirements, environmental conditions, and installation methods, you can make an informed decision on what wire mesh to use in your concrete projects. Whether you opt for welded wire fabric, reinforcing wire mesh, or fiberglass options, the right choice will ensure the durability and longevity of your concrete structures.