Product Details

DOWELCRADLEs are designed for use in concrete slabs or pavements where a sawn or other induced free-movement contraction joint is required. DOWELCRADLEs permit slab movement and ensure free movement of the slab as required, thereby eliminating the principal cause of shrinkage cracks at the joint and minimizing the vertical displacement of the slabs. The system consists of a positioning wire cradle and load transfer system. Dowels and sleeves are held by the cradle, aligned and suspended in position in the middle of the slab with the required dowel spacing, thereby ensuring correct positioning and alignment of the individual dowels and sleeves. The wire cradle pre-sets the height of the dowel in the slab as well as the distance between the centers of the dowels.

Sizes

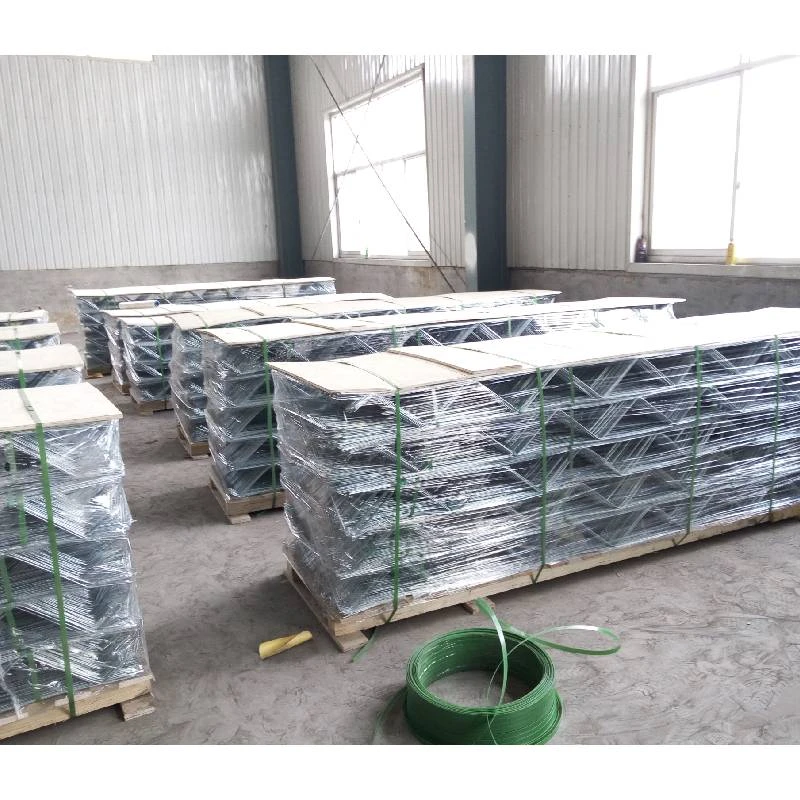

The DOWELCRADLE Load Transfer system allows extremely quick and simple installation of the system by one person. The system is suitable for internal and external slabs with depths from 125 mm to 250 mm. Other sizes can be designed according to the requirements of the client. It is available in plain steel and hot-dip galvanized finish.

Manufacturing Method

DOWEL CRADLES are typically fabricated through prefabrication processes. First, the production of line brackets is ensured to have appropriate strength and dimensions. Then, the pins and sleeves are installed on the brackets to ensure accurate positioning and alignment. Finally, surface treatment, such as galvanizing, is carried out to enhance durability and corrosion resistance.

In addition, any size and shape can be customized according to customer requirements. This means that DOWEL CRADLES can be fabricated according to the design and requirements of specific projects to ensure a perfect fit with existing structures or designs.