Product Content

Material: Low carbon steel wire, Q195,SAE1008 (galvanized steel wire or annealed wire)

Inner Wire Guage: BWG4 ~ BWG25

Inner Wire Diameter: 6mm ~ 0.5mm

Tensile Strength: 300~500 N/mm2

Feature: Our PVC wire with good resilient, fire retardant and possesses good insulating properties,the color are green, grey,black,red or yellow. Other colors also available on request.

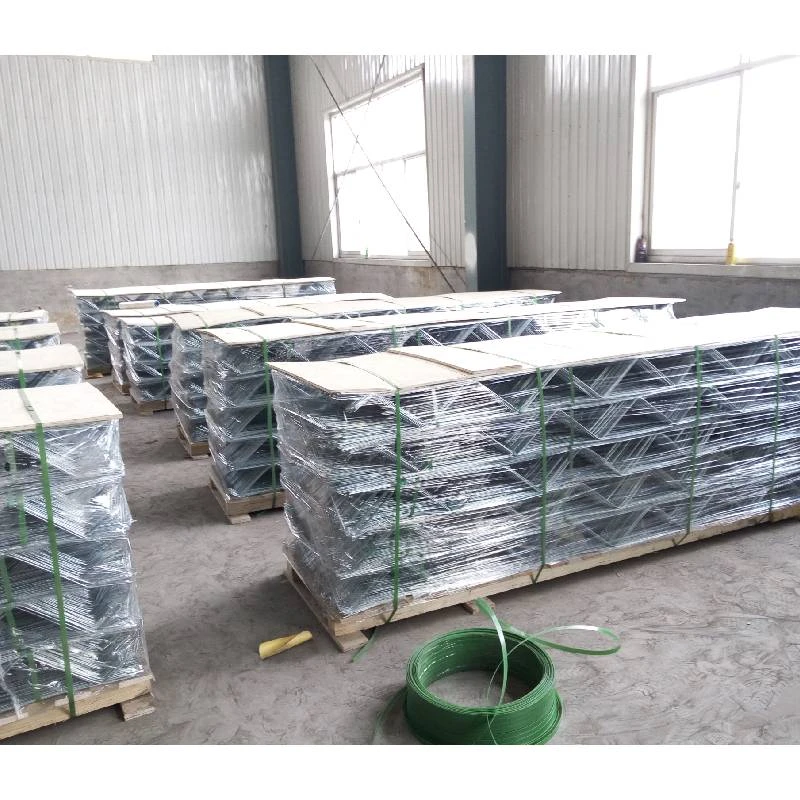

Package:

1.Bind with wire

2.plastic film inside and hessian cloth /woven bag outside

3.Carton

4.Other packing according customer`s requirement.

Weight of coil: 0.1-1000kg/coil, can be make as customers’requirement.

Application: PVC wire widely used in construction building wire,handicrafts, making wire mesh, Marine cable, product packaging, agriculture, animal husbandry and other fields.

|

PVC Coated Wire Specification: |

|

|

Core Wire Diameter |

Outer Diameter |

|

1.0mm -3.5mm |

1.4mm -4.0mm |

|

P.V.C. Coating Thickness : 0.4mm -0.6mm |

|

Product Production Process

The production process of PVC Coated Wire typically involves the following steps:

1. Wire drawing: High-strength low-carbon steel wire is drawn through a wire drawing machine to achieve the desired diameter of the wire.

2. Pickling: The drawn wire is subjected to pickling to remove surface oxides and impurities, preparing the surface for the coating process.

3. Coating: The pickled wire is dipped into a PVC plastic melt to coat the surface with a layer of PVC plastic. This step provides corrosion resistance and durability to the wire.

4. Cooling: The coated wire is allowed to cool, solidifying the PVC coating and creating a uniform surface.

5. Winding: The cooled PVC Coated Wire is wound into rolls for convenient storage and transportation.

Product Application Scenarios

PVC Coated Wire is widely used in various industries, including construction, horticulture, and manufacturing. In construction, it is commonly used for binding reinforcement bars, constructing shelves, and fixing fences. In horticulture, it can be used for creating garden structures, supports for plants, and binding together branches. In manufacturing, it may be used for weaving wire meshes, creating wire products, or as a component in other metal structures.