Contenuto del prodotto

Materiale: filo di acciaio a basso tenore di carbonio, Q195, SAE1008 (filo di acciaio zincato o filo ricotto)

Calibro del filo interno: BWG4 ~ BWG25

Diametro del filo interno: 6 mm ~ 0,5 mm

Resistenza alla trazione: 300~500 N/mm2

Caratteristica: Il nostro filo in PVC ha una buona resilienza, è ignifugo e possiede buone proprietà isolanti, il colore è verde, grigio, nero, rosso o giallo. Disponibili anche altri colori su richiesta.

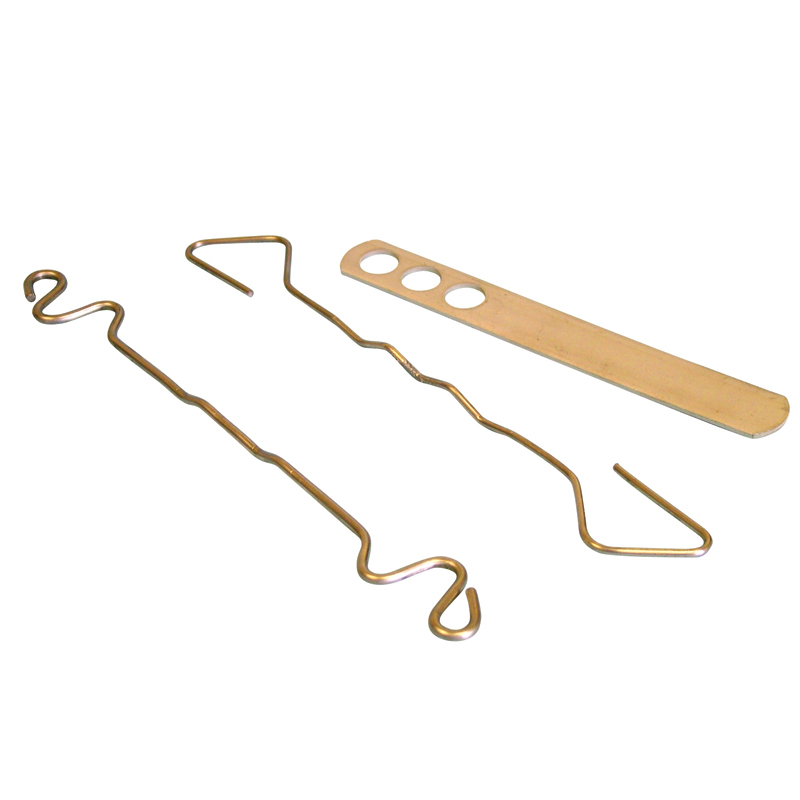

Pacchetto:

1.Rilegare con filo metallico

2. pellicola di plastica all'interno e panno di iuta / borsa tessuta all'esterno

3.Cartone

4. Altro imballaggio in base alle esigenze del cliente.

Peso della bobina: 0,1-1000 kg/bobina, può essere realizzato come requisito del cliente.

Applicazione: filo in PVC ampiamente utilizzato nei cavi per l'edilizia, nell'artigianato, nella realizzazione di reti metalliche, cavi marini, imballaggio di prodotti, agricoltura, zootecnia e altri campi.

|

Specifiche del filo rivestito in PVC: |

|

|

Diametro del filo centrale |

Diametro esterno |

|

1,0 mm-3,5 mm |

1,4 mm-4,0 mm |

|

Spessore del rivestimento in PVC: 0,4 mm -0,6 mm |

|

Processo di produzione del prodotto

Il processo di produzione del filo rivestito in PVC prevede tipicamente le seguenti fasi:

1. Trafilatura: il filo di acciaio a basso tenore di carbonio ad alta resistenza viene trafilato attraverso una macchina per trafilatura per ottenere il diametro desiderato del filo.

2. Decapaggio: Il filo trafilato viene sottoposto a decapaggio per rimuovere ossidi e impurità superficiali, preparando la superficie al processo di rivestimento.

3. Rivestimento: il filo decapato viene immerso in una plastica di PVC fuso per rivestire la superficie con uno strato di plastica di PVC. Questo passaggio fornisce resistenza alla corrosione e durata al filo.

4. Raffreddamento: il filo rivestito viene lasciato raffreddare, solidificando il rivestimento in PVC e creando una superficie uniforme.

5. Avvolgimento: il filo rivestito in PVC raffreddato viene avvolto in rotoli per un comodo stoccaggio e trasporto.

Scenari di applicazione del prodotto

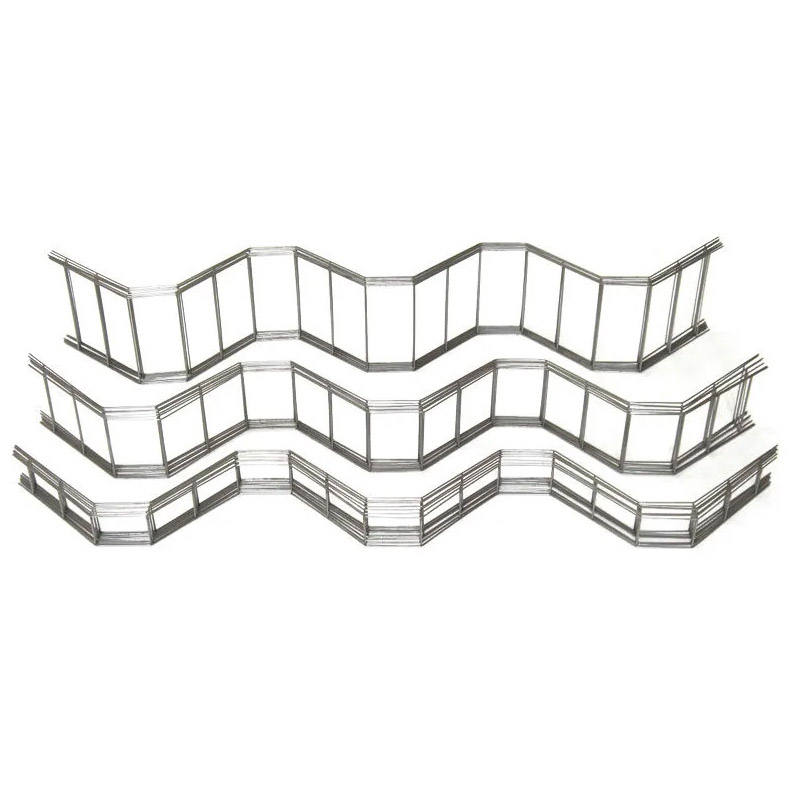

PVC Coated Wire is widely used in various industries, including construction, horticulture, and manufacturing. In construction, it is commonly used for binding reinforcement bars, constructing shelves, and fixing fences. In horticulture, plastic coated iron wire can be used for creating garden structures, supports for plants, and binding together branches. In manufacturing,pvc coated galvanized wire may be used for weaving wire meshes, creating wire products, or as a component in other metal structures.

Why Are Metal Wires Coated with PVC?

Metal wires are coated with PVC primarily to enhance their durability, longevity, and overall performance in various demanding environments. At Shijiazhuang TangChao Metal Products Co., Ltd., we produce top-quality PVC coated iron wire that meets the rigorous requirements of industries worldwide. The key reason for applying a PVC coating is to create a robust protective barrier over the galvanized metal core. This barrier safeguards the wire from exposure to moisture, chemicals, abrasion, and ultraviolet radiation, all of which can accelerate corrosion and degrade the wire’s structural integrity if left unprotected.

The base metal of these wires is usually galvanized iron or steel, which already has a zinc coating to prevent rust. However, zinc protection alone can be insufficient in highly corrosive or outdoor environments. By adding a layer of PVC, the wire gains additional resistance to wear and corrosion, making it suitable for applications requiring long-term exposure to harsh weather or chemicals. The PVC coated galvanized wire also offers enhanced flexibility compared to bare galvanized wire, reducing the likelihood of cracking or breaking when bent or twisted.

Manufacturing this wire involves advanced coating techniques. At TangChao Metal, our factory in Shijiazhuang employs state-of-the-art machinery imported from Germany, Korea, and Taiwan to ensure the pvc gi wire is coated evenly and consistently. This guarantees a smooth, durable layer that adheres firmly to the galvanized surface without gaps or bubbles. This precision reduces the chance of early coating failure and subsequent rust.

Moreover, the coating process allows the wires to be produced in various colors, which is helpful for identification, aesthetics, or safety purposes on construction sites or agricultural setups. For instance, green or black plastic coated galvanized wire is popular in landscaping and farming, blending in with natural surroundings.

In conclusion, coating metal wires with PVC significantly boosts their protective qualities and functional versatility. Thanks to TangChao Metal’s dedication to continuous technological innovation and strict quality management, our pvc coated binding wire is a reliable choice for customers seeking durable, corrosion-resistant metal wire solutions across industries worldwide.

Does PVC Coated Wire Rust?

The concern of rust on PVC coated iron wire is common among users considering these products for outdoor or industrial use. At Shijiazhuang TangChao Metal Products Co., Ltd., we emphasize quality and durability in our manufacturing process to minimize the risk of rust as much as possible. The zinc-coated core of the wire offers a primary layer of corrosion protection by acting sacrificially against oxidizing agents. The additional PVC coating acts as a secondary shield that blocks moisture, salts, and chemicals from reaching the metal.

While it is impossible to guarantee that any coated wire will never rust under all circumstances, proper manufacturing and usage can greatly reduce rust risk. TangChao Metal’s pvc coated galvanized wire undergoes stringent quality inspections to ensure the coating is free from defects such as pinholes, uneven coverage, or peeling, which are common entry points for moisture and corrosive elements. Our advanced production equipment ensures a uniform gi wire pvc coated layer that withstands bending, twisting, and environmental stress.

However, rust can occur if the PVC coating is damaged after installation, for example, through mechanical abrasion, cutting, or prolonged exposure to harsh chemicals that degrade the plastic. It’s essential that users handle the wire carefully during transport and installation to maintain the integrity of the protective PVC layer.

The flexibility of the PVC coating also helps reduce cracks and breaks, which further protects the wire beneath. In applications like construction and agriculture, where wires are often twisted or tied tightly, this flexibility prolongs the lifespan of the wire compared to bare galvanized wire.

TangChao Metal offers competitive pvc coated gi wire price options without compromising on coating quality, helping customers balance cost with long-lasting performance. Our product’s excellent corrosion resistance has earned positive feedback from clients in diverse markets, including the USA, Europe, and Asia.

In summary, while no wire is entirely immune to rust, PVC coated iron wire produced by TangChao Metal combines dual protective layers—galvanization and PVC coating—to offer superior resistance. Proper handling and quality manufacturing are key to ensuring the wire remains rust-free over extended use.

What Is PVC Coated Iron Wire Used For?

PVC coated iron wire is an extremely versatile material used across various industries due to its combination of strength, corrosion resistance, and flexibility. At Shijiazhuang TangChao Metal Products Co., Ltd., we manufacture premium pvc coated gi binding wire designed to meet the needs of construction, agriculture, crafting, and many other sectors.

In construction, this wire plays a crucial role in reinforcing concrete structures. The PVC coating protects the binding wire from corrosion caused by moisture and chemicals in concrete, thereby ensuring structural integrity over time. Our pvc coated binding wire is ideal for tying rebar, securing concrete forms, and supporting scaffolding. The wire’s resistance to rust helps maintain safety and durability on building sites, contributing to longer-lasting projects.

Agricultural uses include fencing, trellising, and plant support. The plastic coated galvanized wire withstands exposure to soil, rain, and fertilizers without degrading quickly, which is essential for outdoor farming environments. Its flexibility allows farmers to shape and bend the wire as needed while retaining strength and corrosion protection.

Moreover, PVC coated iron wire is widely used in landscaping and gardening for creating trellises, garden fences, and decorative supports. The variety of available coating colors enhances aesthetic appeal and helps wires blend seamlessly with plants and outdoor settings. This makes it popular not only with professionals but also DIY enthusiasts.

TangChao Metal’s advanced equipment and skilled workforce ensure that every batch of pvc galvanized wire meets high quality standards. The factory’s annual output of 22 million RMB and export footprint across the USA, Europe, Australia, and Asia testify to our capacity and reliability as a pvc coated iron wire manufacturer.

Finally, this wire is also used in manufacturing processes for producing wire mesh, wire forming, and spring coils where a coated, corrosion-resistant wire is needed. The combination of galvanized core and PVC coating extends the wire’s usable life in these applications, improving cost-effectiveness for producers.

In conclusion, PVC coated gi wire is a highly functional, multi-purpose product with applications in construction, agriculture, landscaping, and manufacturing. TangChao Metal’s products are trusted worldwide for their quality, durability, and performance.