Features

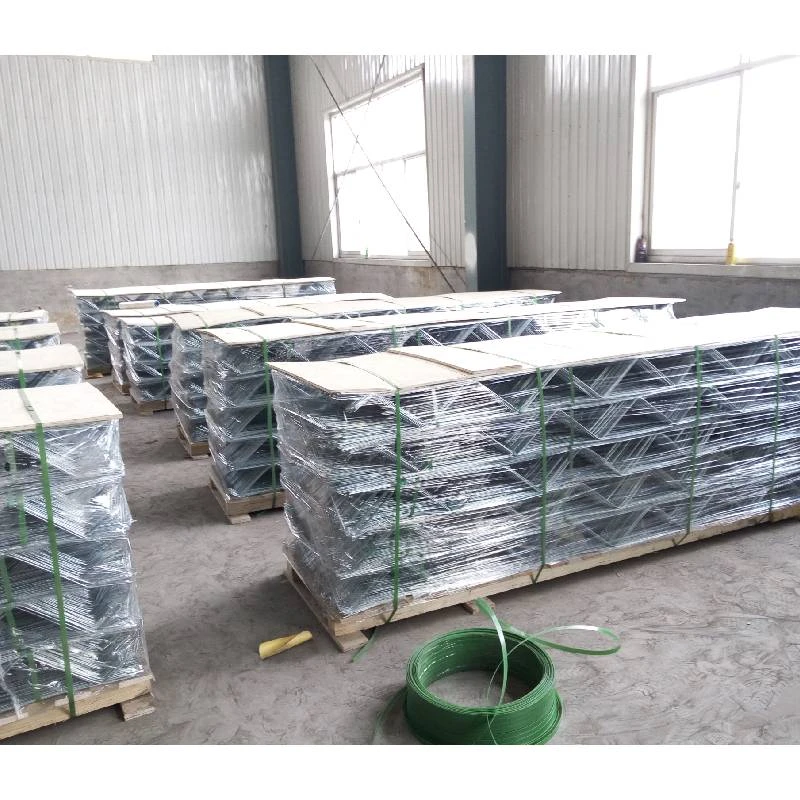

Available in mill galvanized and hot dipped galvanized.

Available in 8" and 12".

Material Conformance

ASTM A951/A951M - (Standard Specification for Steel)

Wire For Mason Joint Reinforcement

ASTM A82/A82M - (Cold Drawn Steel Wire)

Tensile Strength - 80,000 psi

Yield Point - 70,000 psi

Coatings conform to the following specifications:

ASTM A641/A641M (0.1 oz/Ft2 ) for Mill Galvanized coating

ASTM A153/A153M-B2 (1.5 oz/Ft2 ) for Hot-Dip Galvanized

Additional Information

Wire Diameter

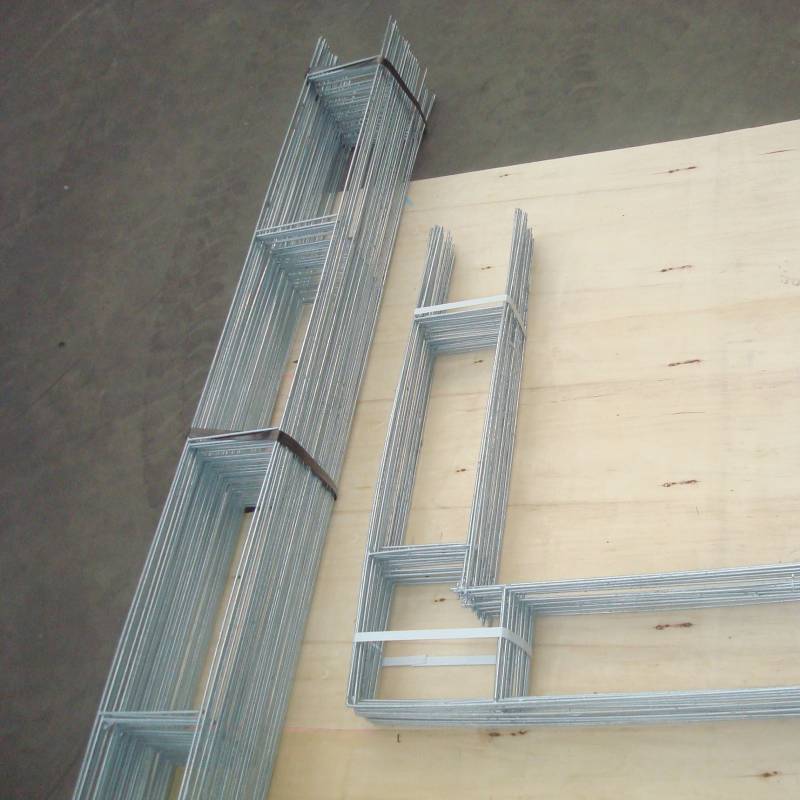

1.9 Gauge (3.75 mm) side rods and cross rods.

2.Cross Rods welded at 16” on center.

3.First Cross Rods welded 12” in from each end to allow lap spaces per code requirements.

Product Advantages

- Durable: The product is made of high-strength steel wire, which has high tensile strength and yield point, and can withstand greater pressure and weight.

- Corrosion Resistance: The product is treated with galvanizing or hot-dip galvanizing, which has good corrosion resistance and can be used in humid and corrosive environments to extend the service life of the product.

- Easy to Install: The product adopts welding technology and is easy to install, which can save construction time and cost.

- Beautiful and generous: The product is made of metal wire mesh, which is beautiful and generous, and can improve the beauty and decoration of the building.

Usage Method

1. Preparation for installation: Before installation, prepare the corresponding tools and materials, such as screwdrivers, wrenches, and welders.

2. Measuring dimensions: According to actual needs, measure the dimensions of the corner, and determine the required product specification and quantity.

3. Installing the product: Install the product at the corner, and fix it with screwdrivers, wrenches, etc.

4. Welding and fixing: Use a welder to weld and fix the product to ensure that the product is firmly installed.

5. Inspection and acceptance: After the installation is completed, check and accept the product to ensure that the product installation meets the requirements.

Manufacturing Process

1. Material selection: Select high-quality steel wire, such as ASTM A82/A82M (cold drawn steel wire), to ensure the quality and performance of the steel wire meet the requirements.

2. Steel wire weaving: Weave the steel wire into a grid to form the basic structure of the product.

3. Welding and fixing: Use a welder to weld and fix the nodes of the steel wire grid to enhance the strength and stability of the product.

4. Surface treatment: Surface treatment can be carried out according to needs, such as galvanizing or hot-dip galvanizing, to improve the corrosion resistance of the product.

5. Inspection and testing: Test and inspect the product to ensure that the product complies with relevant standards and requirements.

Application scenarios

The product is suitable for use in various masonry buildings, such as walls, columns, doors and windows, etc. It can provide extra strength and stability to prevent masonry structures from being damaged in natural disasters such as earthquakes and winds.

Price advantage

The product is made of steel wire and has low production cost, so the price is relatively low. At the same time, the product adopts welding technology, which is easy to install and can save construction time and cost. In addition, the product is treated with galvanizing or hot-dip galvanizing, which has good corrosion resistance and can extend the service life of the product, reducing maintenance costs.