Eegeschaften

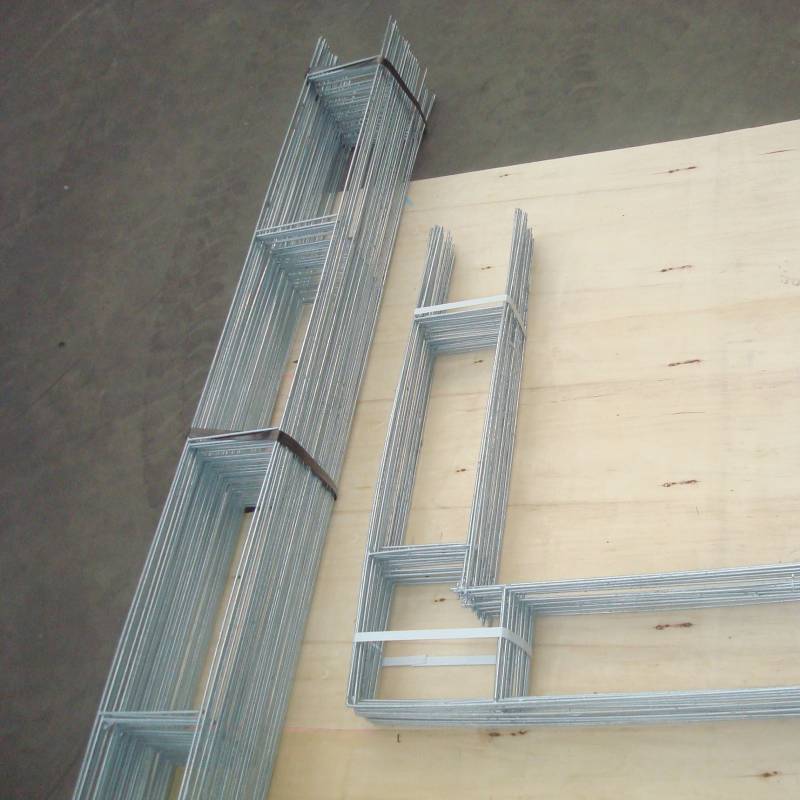

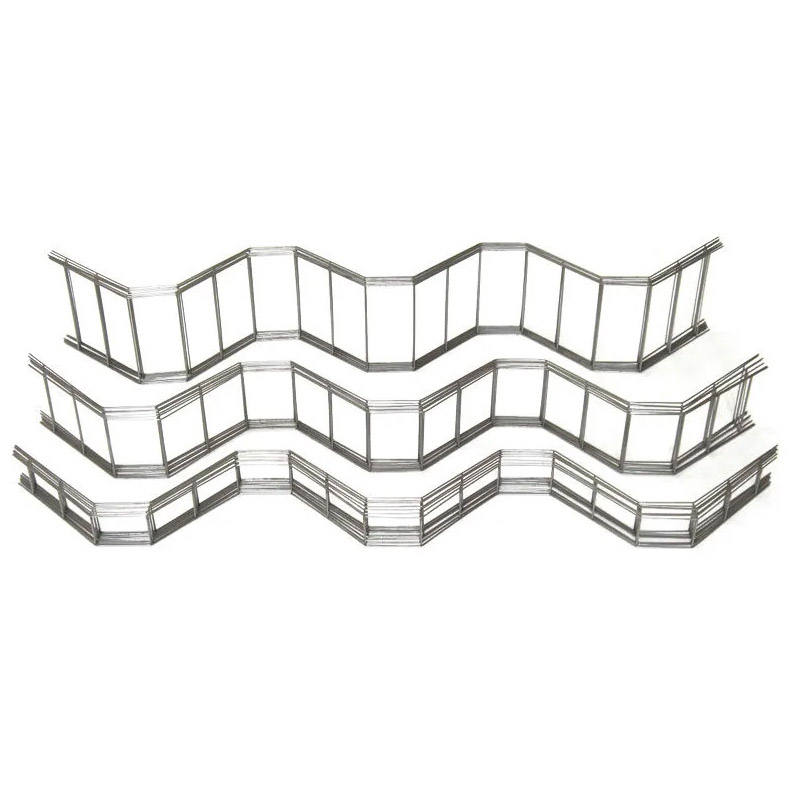

Verfügbar a Millengalvaniséierter a waarmverzinkt.

Verfügbar an 8" an 12".

Material Konformitéit

ASTM A951/A951M - (Standard Specification for Steel)

Drot Fir Mason Joint Verstäerkung

ASTM A82/A82M - (Cold Drawn Steel Wire)

Tensile Stäerkt - 80.000 psi

Ausbezuelungspunkt - 70.000 psi

Beschichtungen entspriechen de folgende Spezifikatioune:

ASTM A641/A641M (0.1 oz/Ft2 ) for Mill Galvanized coating

ASTM A153/A153M-B2 (1.5 oz/Ft2 ) for Hot-Dip Galvanized

zousätzlech Informatiounen

Drot Duerchmiesser

1,9 Jauge (3,75 mm) Säitestangen a Kräizstangen.

2.Cross Rods welded at 16” on center.

3.First Cross Rods welded 12” in from each end to allow lap spaces per code requirements.

Product Advantages

- Durable: The product is made of high-strength steel wire, which has high tensile strength and yield point, and can withstand greater pressure and weight.

- Korrosiounsbeständegkeet: D'Produkt gëtt mat Galvaniséierung oder Hot-Dip Galvaniséierung behandelt, wat gutt Korrosiounsbeständegkeet huet a kann a fiichten a korrosive Ëmfeld benotzt ginn fir d'Liewensdauer vum Produkt ze verlängeren.

- Easy to Install: The product adopts welding technology and is easy to install, which can save construction time and cost.

- Beautiful and generous: The product is made of metal wire mesh, which is beautiful and generous, and can improve the beauty and decoration of the building.

Usage Method

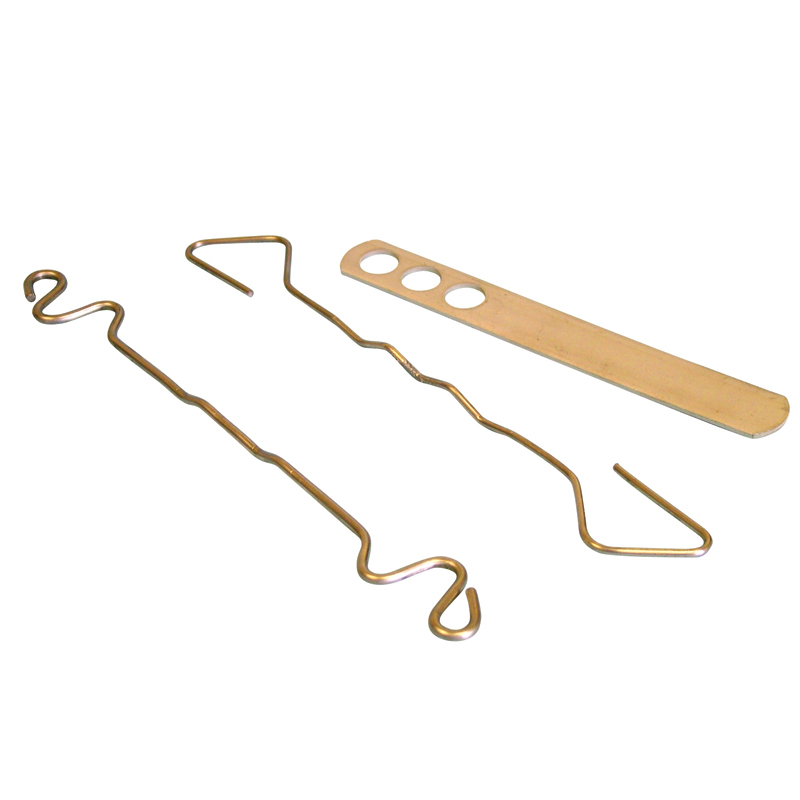

1. Preparation for installation: Before installation, prepare the corresponding tools and materials, such as screwdrivers, wrenches, and welders.

2. Measuring dimensions: According to actual needs, measure the dimensions of the corner, and determine the required product specification and quantity.

3. Installing the product: Install the product at the corner, and fix it with screwdrivers, wrenches, etc.

4. Welding and fixing: Use a welder to weld and fix the product to ensure that the product is firmly installed.

5. Inspection and acceptance: After the installation is completed, check and accept the product to ensure that the product installation meets the requirements.

Manufacturing Process

1. Materialauswiel: Wielt héichqualitativ Stahldraht, wéi ASTM A82 / A82M (kal gezunnen Stahldraht), fir d'Qualitéit an d'Leeschtung vum Stahldrot den Ufuerderungen ze garantéieren.

2. Steel wire weaving: Weave the steel wire into a grid to form the basic structure of the product.

3. Welding and fixing: Use a welder to weld and fix the nodes of the steel wire grid to enhance the strength and stability of the product.

4. Surface Behandlung: Surface Behandlung kann no Bedierfnesser duerchgefouert ginn, wéi zB Galvaniséierung oder Hot-Dip Galvaniséierung, fir d'Korrosiounsbeständegkeet vum Produkt ze verbesseren.

5. Inspection and testing: Test and inspect the product to ensure that the product complies with relevant standards and requirements.

Applikatioun Szenarie

The product is suitable for use in various masonry buildings, such as walls, columns, doors and windows, etc. It can provide extra strength and stability to prevent masonry structures from being damaged in natural disasters such as earthquakes and winds.

Price advantage

De Produit ass aus Stol Drot gemaach an huet niddereg Produktioun Käschten, sou ass de Präis relativ niddereg. Zur selwechter Zäit adoptéiert de Produit Schweißtechnologie, déi einfach ze installéieren ass a Bauzäit a Käschten spuere kann. Zousätzlech gëtt de Produit mat Galvaniséierung oder Hot-Dip Galvaniséierung behandelt, wat gutt Korrosiounsbeständegkeet huet an d'Liewensdauer vum Produkt verlängeren kann, d'Ënnerhaltskäschte reduzéieren.