Detailed description

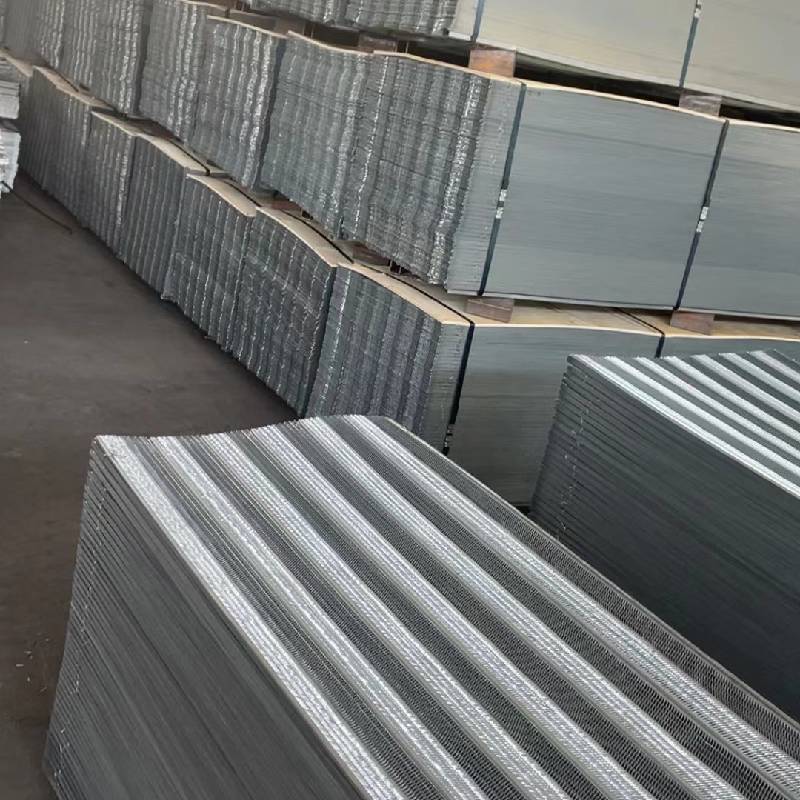

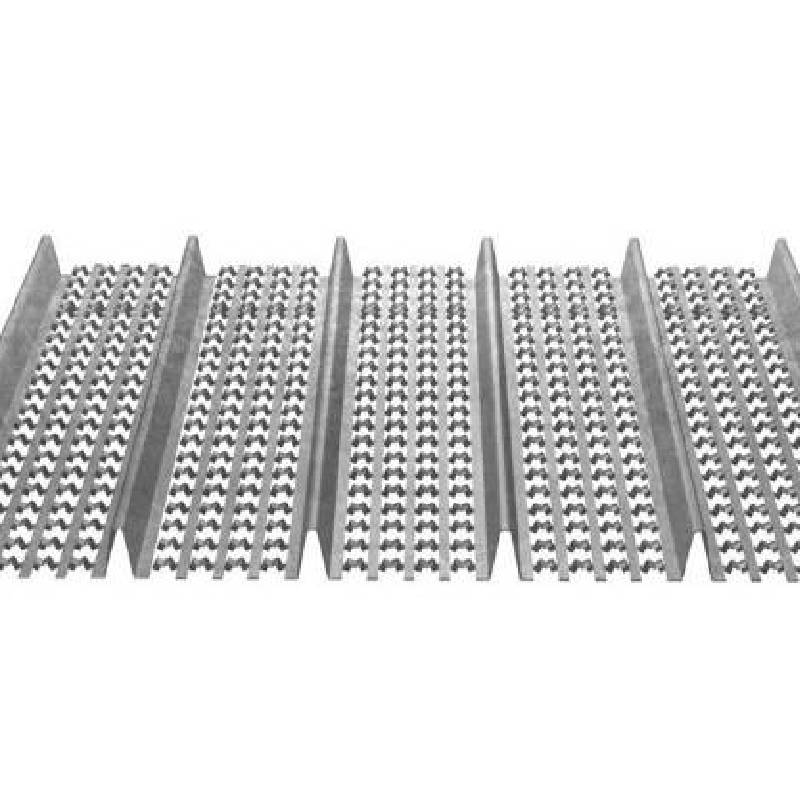

Galvanized Hy Rib Mesh is a metal mesh made of hot-dipped galvanized steel plate. Its mesh structure and U-shaped pattern give it better stress resistance and forming flexibility, making it more advantageous than ordinary metal plates. This product has excellent engineering quality and construction safety and is widely used in tunnel bridges, valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards, water tanks and marine engineering, as well as high-rise building projects. As a permanent formwork support structure for concrete, it can provide stable support and accurate size control to ensure the uniform distribution and correct forming of concrete.

Detailed parameters

|

Model |

Thickness (mm) |

Weight (kg) |

Width (mm) |

Length (mm) |

Rib Height (mm) |

Rib Distance(mm) |

|

018 |

0.18 |

1.35 |

450 |

2200 |

15 |

90 |

|

021 |

0.21 |

1.60 |

450 |

2200 |

15 |

90 |

|

023 |

0.23 |

1.70 |

450 |

2200 |

15 |

90 |

|

025 |

0.25 |

1.90 |

450 |

2200 |

15 |

90 |

|

030 |

0.30 |

2.45 |

450 |

2200 |

15 |

90 |

|

035 |

0.35 |

2.90 |

450 |

2200 |

15 |

90 |

|

0.40 |

0.40 |

3.30 |

450 |

2200 |

15 |

90 |

Application industries

Galvanized Hy Rib Mesh is widely used in the construction industry, especially in the construction of concrete structures. It can be used for formwork support in walls, ceilings, and floors to provide a stable foundation and ensure the uniform distribution and correct forming of concrete. In addition, Galvanized Hy Rib Mesh can also be used in infrastructure projects such as bridge, road, and tunnel construction, as well as in the construction of industrial structures.

Manufacturing method

The manufacturing of Galvanized Hy Rib Mesh usually includes the following steps:

1、Using high-strength steel plate, it is processed into the required mesh structure and U-shaped pattern by stamping, cutting, or welding.

2、Hot-dip galvanizing: To improve the corrosion resistance and service life of the mesh, it is usually treated with hot-dip galvanizing.

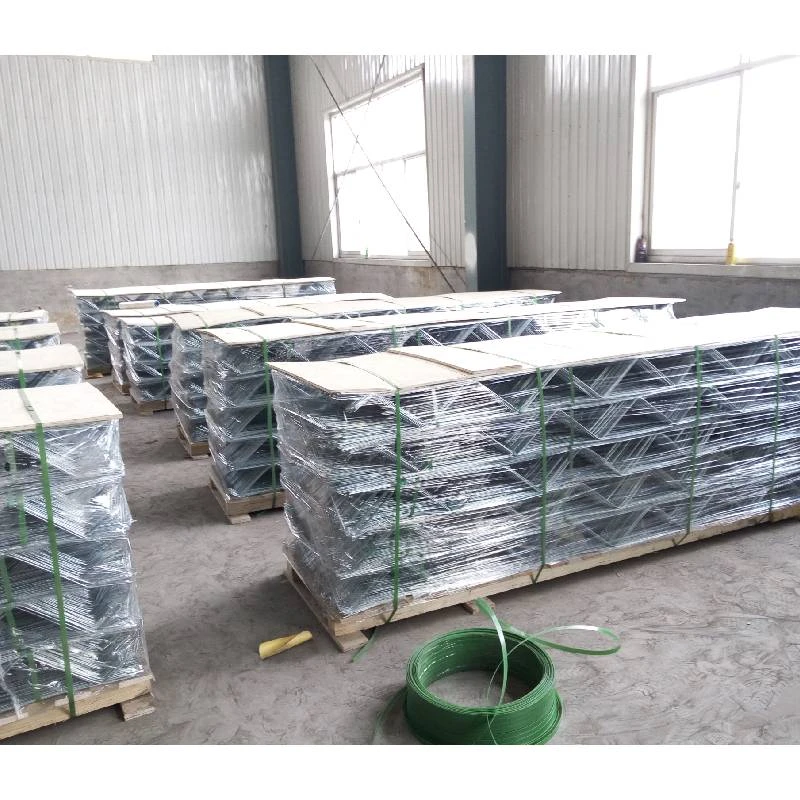

3、Cutting and forming: The processed mesh is cut and formed according to specific needs to adapt to different sizes and shapes.