Product Description

Material: Low carbon steel Q195, Q23 .made by high quality low carbon steel wire through the process of wire drawing, acid washing, rust removing and annealing.

Feature: can offer excellent flexibility and plasticity, can be used widely.

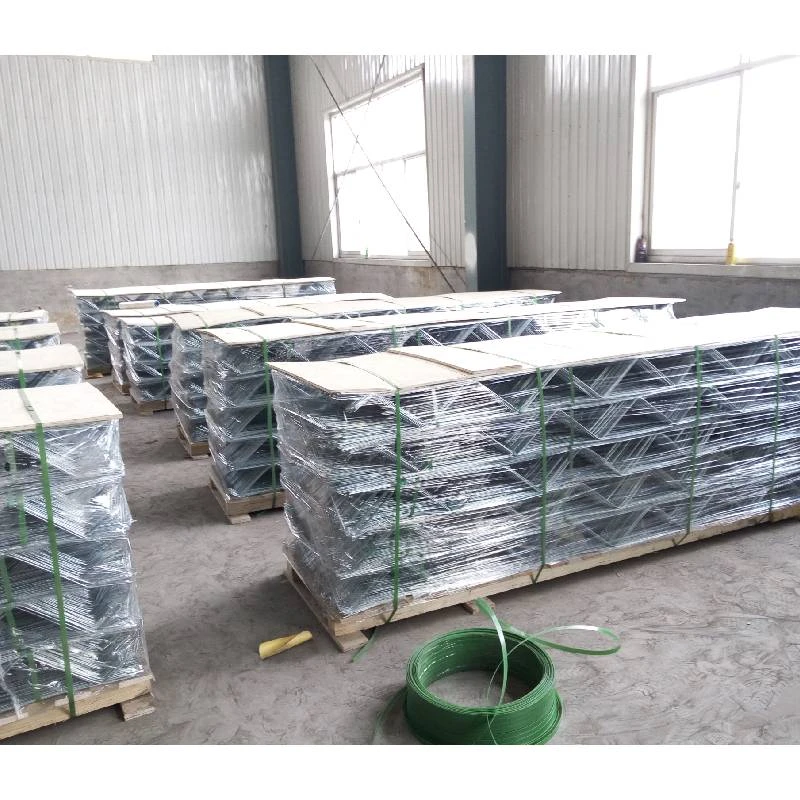

Packagein rolls; plastic film inside, woven bag or hessian cloth outside.

Weight25kg & 50kg/roll or as you need.

Application Widely used in weaving wire mesh, products packing, handcraft, binding for construction and daily use.

Product Usage

This wire can be used to weave various types of wire meshes, such as protective nets and filter screens. It can also be used in product packaging, such as tying, fixing, or packaging items. In handcraft production, black annealed wire can be used to make various handicrafts, such as jewelry and ornaments. In addition, it can also be used in the construction field, such as fixing scaffolding and tying rebars.

Production Process

The production process of black annealed wire includes wire drawing, pickling, rust removal, and annealing. Firstly, the raw material of low-carbon steel is drawn into the required diameter through a wire drawing machine. Then, acid pickling is carried out to remove surface oxides and impurities. Next, the rust removal process is used to remove the rust on the surface of the steel wire. Finally, the annealing treatment is performed to make the grain structure of the steel wire more uniform and improve its flexibility.