製品説明

材料: Low carbon steel Q195, Q235. Made from high-quality low carbon steel wire through processes such as wire drawing, acid washing, rust removal, and annealing, this wire delivers reliable strength and ductility. It is commonly known as annealed wire, and in its darkened form, it is often referred to as black annealed iron wire or soft annealed wire.

特徴: Offers excellent flexibility and plasticity, making it ideal for multiple uses. As a widely preferred annealed tie wire, it is easy to handle and shape during various tasks.

パッケージインロール;内側はプラスチックフィルム、外側は織袋またはヘシアン布です。

Weight25kg & 50kg/ロールまたは必要に応じて。

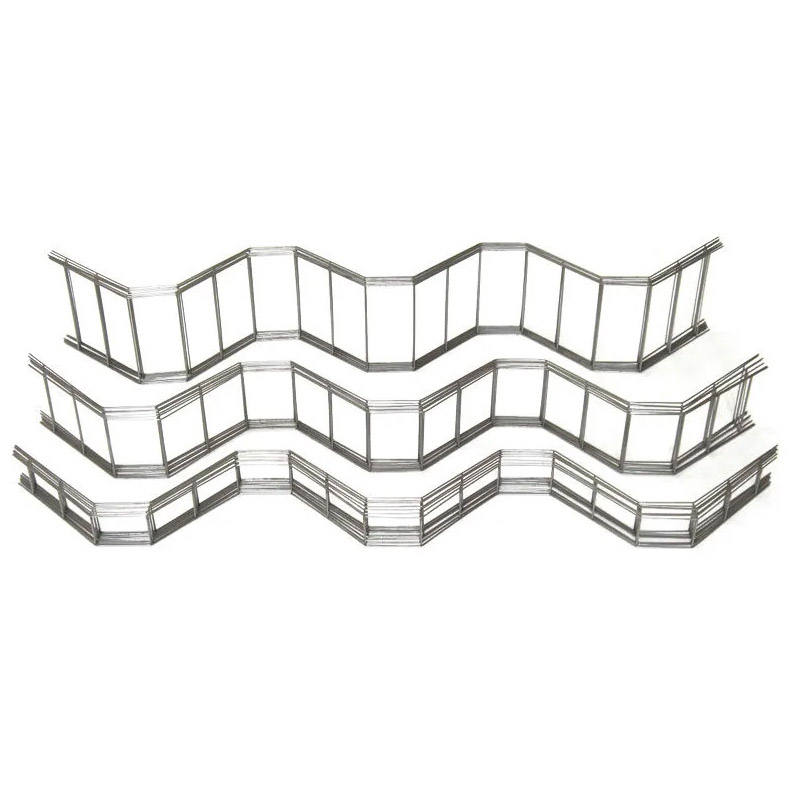

用途ワイヤーメッシュの織り、製品の梱包、手工芸品、建築用の結束、日常使用などに広く使用されています。

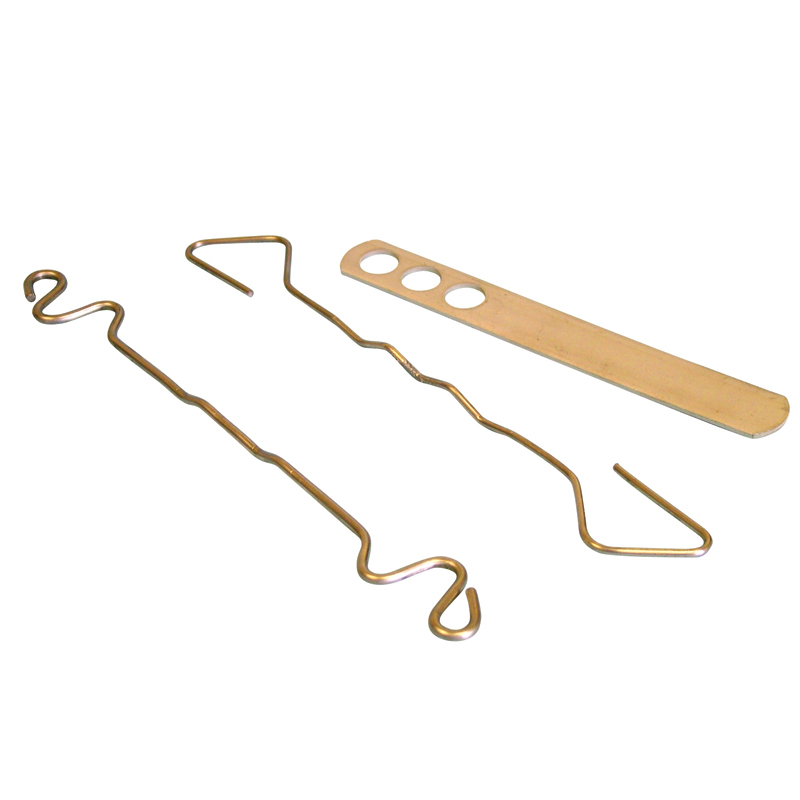

製品の使用法

This wire can be used to weave various types of チェーンフェンス, such as protective nets and filter screens. It can also be used in product packaging, such as tying, fixing, or packaging items. In handcraft production, black annealed wire can be used to make various handicrafts, such as jewelry and ornaments. In addition, it can also be used in the construction field, such as fixing scaffolding and tying rebars.

生産工程

黒焼鈍線の製造工程は、伸線、酸洗、除錆、焼鈍となります。まず、原料の低炭素鋼を伸線機で必要な直径に引き抜きます。次に、酸洗を行って表面の酸化物や不純物を除去します。次に、鋼線の表面の錆を除去する「錆取り工程」を行います。最後に、鋼線の結晶粒構造をより均一にし、柔軟性を向上させるために焼鈍処理が行われます。

Black Annealed Wire vs Galvanized

In construction, agriculture, and industrial packaging, black annealed wire and galvanized wire are two essential materials, yet their roles and characteristics are often misunderstood or used interchangeably. In fact, the choice between them can significantly impact the performance, cost, and durability of your project.

Black annealed wire is made from low-carbon steel that is drawn and then softened through a high-temperature annealing process. This gives it excellent ductility, flexibility, and a smooth black finish, making it an ideal solution for tying, bending, and bundling in dry or indoor environments. Galvanized wire, on the other hand, undergoes a zinc-coating process, either through hot-dipping or electroplating, which forms a protective layer against corrosion. As a result, it becomes more rigid and durable in harsh weather conditions, especially for outdoor use like fencing and electrical grounding.

TangChao Metal, a reputable black annealed wire manufacturer located in Hebei Province, has specialized in wire production since 1998. With German- and Korean-imported equipment, and a 7,000 square meter facility supported by 80 skilled employees, we deliver high-performance black annealed steel wire and galvanized iron wire to more than 20 countries worldwide, including the U.S., Japan, Saudi Arabia, and Australia.

The difference in physical properties is critical. If you’re working on tasks that require repeated twisting or manual tying, such as rebar binding or packaging, black annealed wire—particularly annealed tie wire or annealed black wire—is the better choice due to its softness and flexibility. Galvanized wire, although more rust-resistant, may crack or fatigue more quickly under constant bending stress. Meanwhile, when moisture, rain, or chemical exposure is expected, galvanized steel wire performs better because of its protective coating.

Cost is another important factor. Black annealed wire is generally more economical than galvanized wire. For temporary structures or indoor applications where corrosion resistance isn’t a concern, black annealed options offer excellent value. TangChao Metal supplies both wire types at competitive pricing without sacrificing quality, thanks to our rigorous inspection standards and modern production technology.

Ultimately, your choice comes down to the conditions in which the wire will be used. Black annealed wire offers workability, while galvanized wire ensures durability. At TangChao, we help customers choose the right wire for their projects based on real-world performance, not just specifications. With decades of manufacturing expertise and a commitment to precision and service, we’re proud to be among the trusted black annealed wire suppliers in the global market.

Black Annealed Wire Specifications Overview

Black annealed wire is a soft, low-carbon steel wire widely used for binding, baling, and construction tying. Its performance in these applications depends largely on its core specifications, such as material grade, diameter, tensile strength, and surface finish. At TangChao Metal, we have been manufacturing and exporting black annealed wire products since 1998, leveraging advanced machinery imported from Germany and Korea to ensure consistency and high production capacity.

Our wire is produced using Q195 or Q235 low-carbon steel. After the initial wire-drawing stage, it undergoes an annealing process in a temperature-controlled furnace to reduce hardness and increase ductility. This gives the wire its characteristic softness and black oxide surface. The annealed wire becomes easier to bend, cut, and twist—making it ideal for use in construction sites, recycling centers, and packaging facilities. The black color isn’t painted—it results from the heat treatment and indicates the wire’s readiness for use in flexible applications.

TangChao’s black annealed baling wire and annealed binding wire come in a variety of sizes, typically ranging from 0.5 mm to 5.0 mm in diameter. Popular sizes like 1.2 mm and 2.0 mm are frequently used in rebar tying and carton packaging. Despite its softness, our soft annealed iron wire offers stable tensile strength between 350 to 550 MPa, ensuring it can hold material firmly while remaining pliable during use. The balance between strength and softness is a result of precise temperature control during annealing—a technique we’ve mastered over 25 years of production.

In terms of surface condition, the wire may be slightly oiled to improve resistance against short-term oxidation, especially during transport or storage. Packaging formats are flexible—coils can be supplied from 1 kg up to 500 kg depending on customer needs, and export-grade packaging includes plastic film, woven bags, or pallets, ensuring safe delivery to over 20 countries where TangChao Metal is an active exporter.

Whether you need wire for daily use in construction or large-scale agricultural distribution, we can meet your demand with precision and speed. As an experienced black annealed wire supplier, we manufacture according to international standards such as ASTM or BS, and provide customized solutions tailored to local market requirements. Clients from Europe, Southeast Asia, and the Middle East rely on TangChao for not only consistent quality but also transparent communication, timely delivery, and technical support. Our goal is simple: to deliver soft, strong, and reliable black annealed steel wire that exceeds expectations across every application.

How Is Black Annealed Wire Made?

The production of black annealed wire is a precise, quality-driven process that blends material science, advanced equipment, and years of industry expertise. At Shijiazhuang TangChao Metal Products Co., Ltd., a trusted name in wire solutions since 1998, we approach this process with a deep understanding of steel behavior and performance requirements.

It all begins with low-carbon steel wire, which is drawn to a specified diameter through a cold-drawing machine. This step determines the basic mechanical properties of the wire. Next comes the cleaning phase—our technicians use pickling solutions to remove surface impurities and oxides, ensuring a clean substrate for the heat treatment that follows. This cleaning is essential for a consistent annealing result.

Annealing is the core of this transformation. The wire is heated in a controlled environment to approximately 800°C and then cooled slowly in a sealed furnace to avoid oxidation. This critical step alters the microstructure of the steel, softening the material and improving its flexibility and ductility. This is how we achieve the desirable black oxide finish, giving the black annealed wire its characteristic dark color and surface texture.

As a result, the wire is easier to bend and twist, making it ideal for annealed tie wire, baling, and construction uses. At TangChao Metal, we use state-of-the-art annealing furnaces imported from Germany and Korea, which enable us to guarantee uniformity across large production volumes. Our facility, covering 7,000 square meters, supports a streamlined workflow that maintains both efficiency and stringent quality control.

Each coil is subjected to thorough inspection—tensile strength, elongation rate, and surface smoothness are rigorously tested by our 30+ technical experts. We also provide customization services for wire diameter, coil weight, and packaging styles, meeting the demands of global clients from Europe to the Middle East.

In summary, our annealed wire is not just a product—it is the result of decades of experience, advanced machinery, and a commitment to consistent quality. Whether you require it for binding, fencing, or structural reinforcement, you can trust that TangChao’s process delivers wire that works harder and lasts longer.

Why Choose Black Annealed Steel Wire?

When it comes to finding the right material for tying, binding, or baling in construction and agriculture, black annealed steel wire stands out for its strength, flexibility, and finish. It’s not just a utility material—it’s a critical component in workflows where performance and reliability matter.

So, what sets this wire apart? First, it’s the balance of softness and strength. Through a precise annealing process, black annealed steel iron wire retains enough tensile strength for secure tying, while remaining pliable enough for easy manual or automated use. This makes it an excellent option for annealed binding wire applications in masonry, rebar tying, or as a core material in pre-cast systems.

Second, the surface finish matters. The black oxide layer offers mild corrosion resistance and better grip, especially for rebar or bundled materials. It's the finish preferred by professionals across the construction and packaging industries, especially in humid or dust-prone environments.

At TangChao Metal, our team leverages over two decades of manufacturing experience and international trade. Our products are already trusted by clients in the U.S., Europe, Japan, and the UAE. That global footprint reflects not only our high manufacturing standards but also our ability to tailor specifications—whether you need 16 gauge or 18 gauge wire, in 50 kg coils or smaller spools.

Moreover, we ensure that our annealed black wire complies with both domestic and international standards. Every batch is produced with low-carbon steel and tested to guarantee consistent mechanical behavior. We even offer OEM labeling and export-ready packaging—whether you’re a distributor or end user, working with TangChao means you’re backed by a company that understands both product and market.

Choosing TangChao’s black annealed steel wire means choosing a wire that performs reliably every time, whether it’s securing formwork, bundling materials, or used in fencing or vineyard applications. It’s engineered to meet today’s professional demands—with the service and scale to keep you moving.

Looking for Black Annealed Wire Suppliers?

Finding dependable black annealed wire suppliers can make or break your project timelines, quality standards, and long-term partnerships. At Shijiazhuang TangChao Metal Products Co., Ltd., we go beyond simply delivering wire—we deliver trust, consistency, and international-grade service.

Established in 1998 in Hebei Province, China, TangChao Metal has grown into one of the most reliable black annealed wire suppliers in Asia. With an annual output value reaching 22 million RMB and a dedicated team of 80 employees—including 30 skilled technicians—we serve over a dozen international markets, including the USA, EU, Canada, Saudi Arabia, and South Korea.

What sets us apart is not just our high-grade product line that includes black annealed tie wire, galvanized wire, and wire mesh, but also our ability to offer end-to-end service. From custom wire forming to private-label packaging, we understand the dynamics of both OEM and direct industrial supply.

Our black annealed wire is produced using the latest imported equipment from Germany, Korea, and Taiwan. That means better tensile accuracy, fewer breaks during usage, and consistent diameters coil after coil. We welcome inspection, offer full test reports, and guarantee shipment timelines with proactive tracking and after-sales support.

Are you a rebar fabricator in the UAE? A hardware distributor in Australia? Or a fencing contractor in Canada? No matter your business model, our team will provide a tailored quotation, shipping plan, and wire specification based on your project’s unique requirements. We believe great products deserve great communication—our export team speaks fluent English and understands international logistics.

With TangChao, you don't just get soft annealed iron wire—you get a dependable partnership built on accountability and continuous improvement. As we continue to grow globally, we’re looking to build long-term relationships with businesses that value quality, flexibility, and real-world performance.