Product Advantages

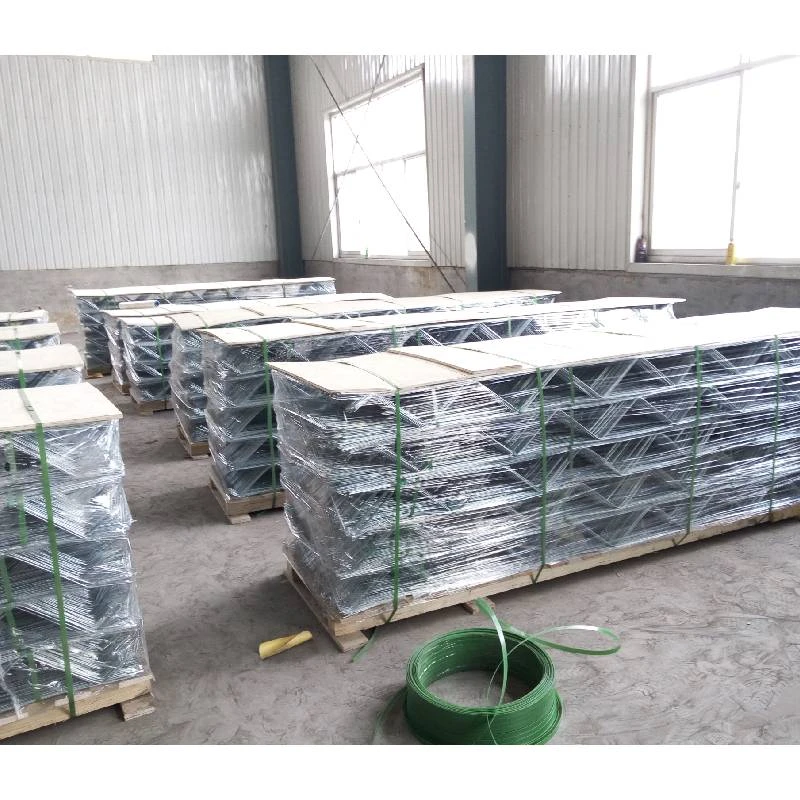

1. High strength and stability: Made of high-strength stainless steel or hot-dipped galvanized steel wire, it has high strength and load-bearing capacity, effectively resisting tension and deformation to ensure a firm connection between the brick veneer and the support structure.

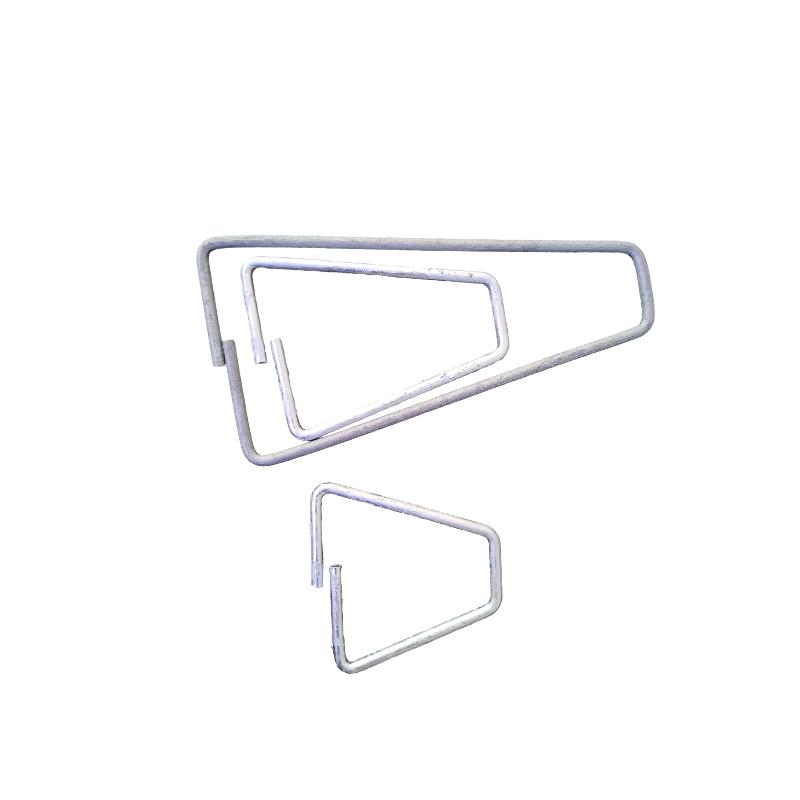

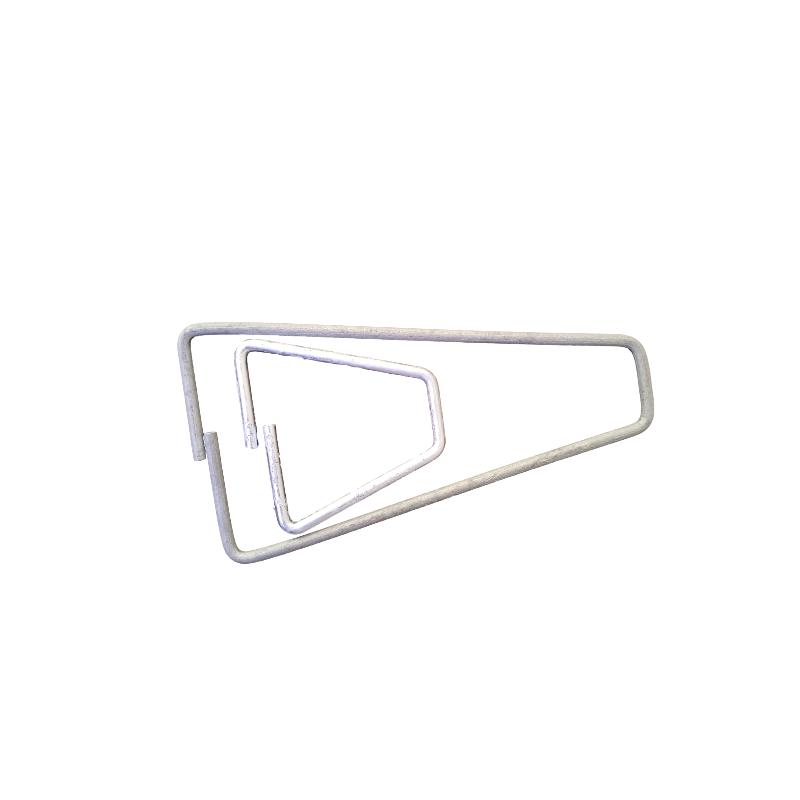

2. Easy installation and adjustment: Simple in design and easy to install, it can be adjusted as needed to fit different support structures and brick veneer sizes.

3. Corrosion resistance: It is treated with stainless or hot-dipped galvanized surface treatment for enhanced corrosion resistance and extended service life.

4. Customizable: Customizable in size and material to meet specific requirements.

Product Instructions

1. Determine the installation position: Based on the design requirements, determine the installation position and spacing of the ties.

2. Install the ties: Hook one end of the tie onto the anchor point of the support structure and embed the other end in the mortar joint of the brick veneer wall.

3. Adjust the ties: Adjust the length and angle of the ties as needed to ensure a tight connection between the brick veneer and the support structure.

4. Inspection and acceptance: After installation, inspect the quality of the ties to ensure compliance.

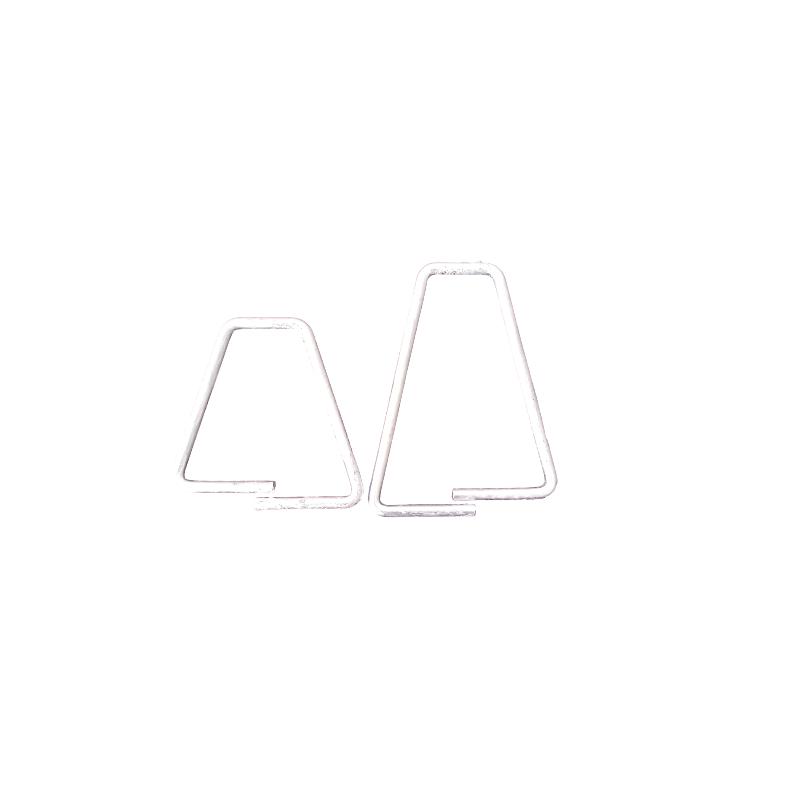

The production process of Triangular Wire Tie typically involves bending high-strength stainless steel or hot-dipped galvanized steel wire into a triangle shape.

Product Application Scenarios

It is mainly used in connecting brick veneers to support structures such as brick veneer exterior walls, interior walls, and parapets. It provides extra strength and stability, preventing brick veneers from being damaged during earthquakes, winds, or other natural disasters.

Product Price Advantage

Relatively low in price, it is an economical and practical anchoring solution. Its simple design and manufacturing process result in lower production costs, offering competitive prices to users.