Product Description

The perfect wire for tying reinforcing mesh and general construction tying. 1.57mm x 95m rolls

- 1.57mm x 95m

- Perfect for tying reinforcing mesh or fencing

- Fits neatly into Belt Pak reel for easy dispensing

The perfect wire for concreting and general construction tying. Made from strong durable steel wire, this wire is perfect tying off reinforcing and all types of fencing

Detailed description: This tie wire is an ideal choice for binding reinforcement meshes and general construction tying. Each roll is 95 meters long and has a diameter of 1.57 millimeters. It is made of high-strength steel wire and undergoes special treatment to have corrosion resistance and good flexibility. This tie wire is suitable for various construction projects, such as house construction, bridges, roads, tunnels, etc. It can effectively fix and connect construction materials such as rebars, steel pipes, and cables to ensure the stability and safety of the structure.

Specifications

- Diameter: 10 gauge to 20 gauge.

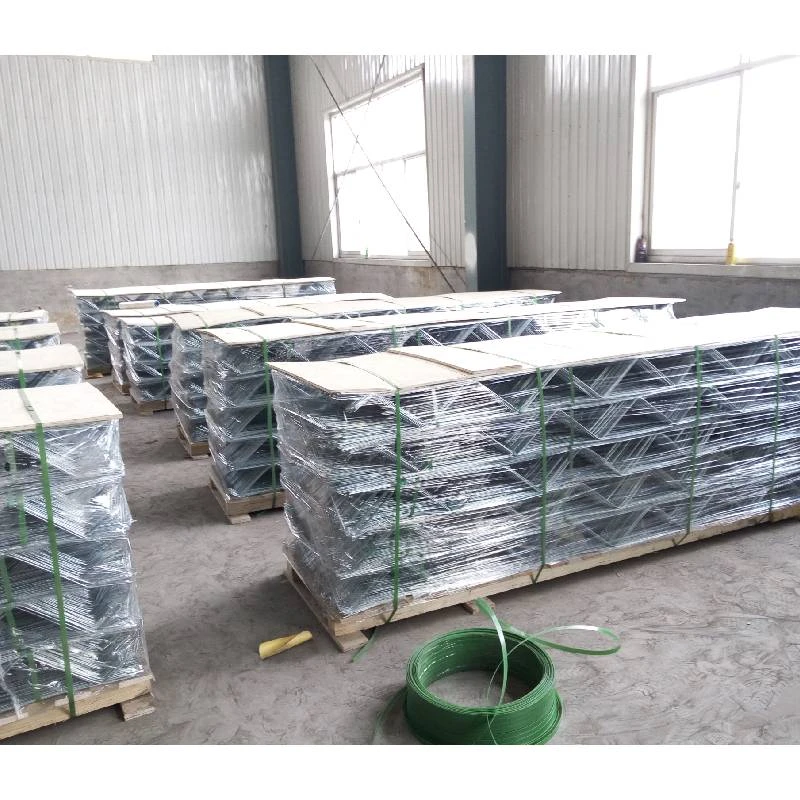

- Package: plastic film, carton and pallet package.

- Loading: 2.5 or 3.5 lbs./coil, 20 coils/carton, 48 cartons/pallets, 13 pallets/20' GP container.

WIRE TYPE :

1.Galvanized wire

2.Black annealed wire

3.PVC coated wire

4.Stainless steel wire,

5.Cooper wire, brass wire.etc

Product Application Scenarios

Application industries:In addition to being widely used in the construction industry for binding reinforcement meshes, it can also be used in other fields. For example, in agriculture, it can be used to fix fences, hedges, and support plants. In the manufacturing industry, it can be used to bind and fix various materials, such as metals, woods, and plastics. In addition, this type of tie wire may also be used in some craft and DIY projects, such as making handicrafts, furniture, barbecue grills, etc.

Product Production Process

Manufacturing method:The production of this tie wire usually includes the following steps: Wire drawing: The high-strength steel wire is stretched through a wire drawing machine to reduce its diameter to the required size. Surface treatment: The drawn steel wire is surface-treated to increase its corrosion resistance and bonding strength with concrete. Common surface treatment methods include galvanizing and coating with epoxy resin. Winding into bundles: The surface-treated steel wire is wound into bundles for easy storage, transportation, and use.