Product Description

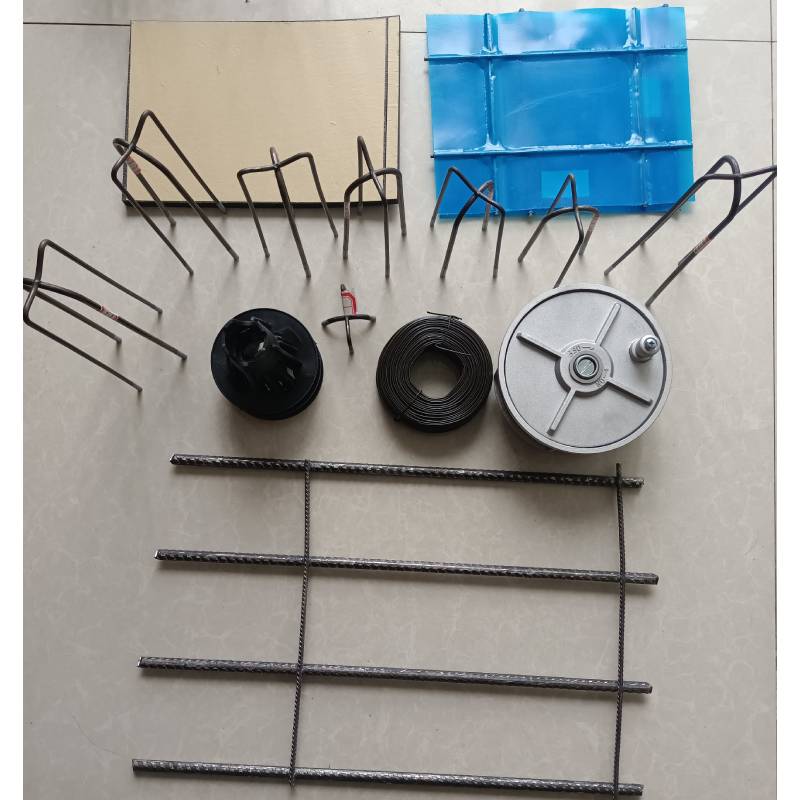

1.Materials: Low carbon steel

2.Wire Diameter: 4.0mm-6.0mm

3.Height: 20mm-400mm

4.Leg Type: straight leg, bent leg

5.Leg Surface Treatment: PVC, PE powder Coated, Liquid Coated

6.Variety: Individual Slab Bolster, Continuous Slab Bolster

7.Feature: Anti-static, Anti-rust, Good Stability, Save time and cost, Extremely small tolerance

Other Sizes Can Also Produced According to Customers' Need.

Application

Reinforcing steel concrete rebar chair/high chair widly use in support steel of concrete,builings,street construction and bridge buliding.

Steel rebar support chair is welded with new technology, mainly used for big construction industry, as joint linking single or multi-layer reinforced steel bars. With great strength, flexibility, anti-static, and environmental protection, this kind of steel bar support can greatly improve the quality of the project, save cost and time. By using of steel bar support, the construction time can be saved and the speed can be accelerated to reduce the construction cycle.

The Construction Steel Rebar Support Chair/Wire Spacers, also known as wire spacers, are support devices made of steel wire through a new welding technology. They are mainly used in the construction of buildings to provide support for reinforcement mesh and steel bars when laying concrete slabs or formworks. Their legs are protected with a plastic film to prevent rust from penetrating the concrete and causing concrete cancer.

Product Advantages

1. High strength and stability: Made of high-strength steel wire, they have high strength and load-bearing capacity, effectively supporting the reinforcement mesh and steel bars and ensuring the stability of the concrete structure.

2. Prevention of concrete diseases: The legs are protected with a plastic film to prevent rust from penetrating the concrete and reduce the risk of concrete diseases.

3. Easy installation and adjustment: The design is simple and easy to install. They can be adjusted as needed to meet different requirements of steel bar spacing and size.

4. Improve construction efficiency: They can be quickly installed and adjusted, reducing construction time and labor costs and improving construction efficiency.

5. Cost-effective: They are produced with new welding technology, resulting in low production costs and relatively economic prices.

Product Instructions

- Determine the installation position: According to the design requirements, determine the installation position and spacing of the wire spacers.

- Install the wire spacers: Place the wire spacers in the position to ensure a firm contact with the surface of the formwork or foundation.

- Place the reinforcement mesh and steel bars: Place the reinforcement mesh and steel bars on the wire spacers, ensuring a certain distance between the steel bars and the legs of the wire spacers.

- Pour concrete: After installing the reinforcement mesh and steel bars, pour the concrete to ensure the complete filling of the formwork and around the wire spacers.

- Removal and cleaning: After the concrete solidifies, remove the wire spacers and clean the surface.

1. Material selection: High-strength steel wire is selected as the raw material to ensure the load-bearing capacity of the wire spacers.

Product Production Process

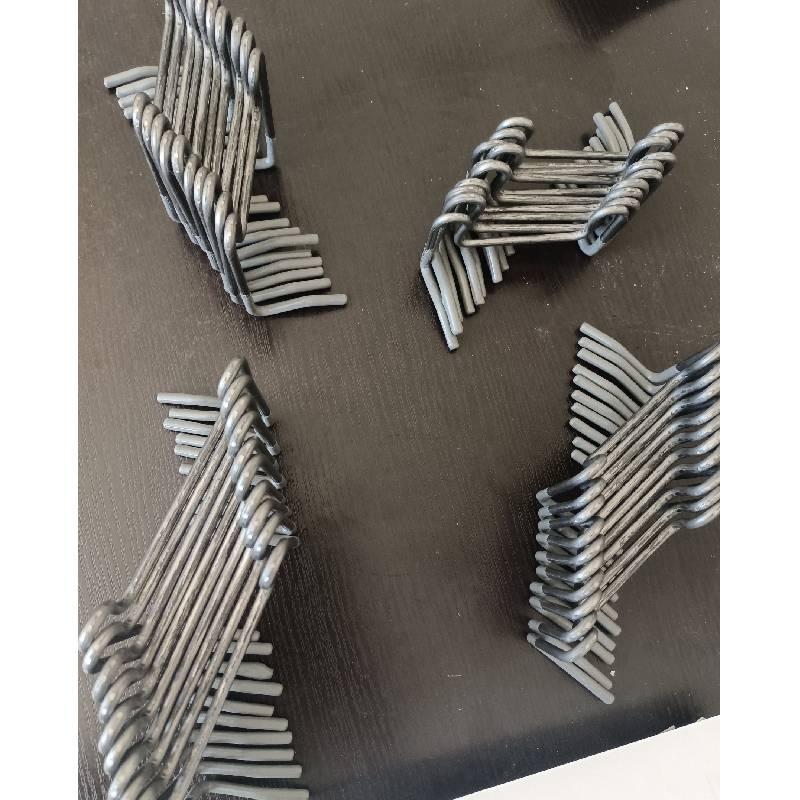

2. Wire processing: Use professional wire processing equipment to bend the steel wire into the required shape to form the main structure of the wire spacers.

3. Welding: Adopt new welding technology to weld the various parts of the wire spacers together to ensure the stability and load-bearing capacity of the structure.

4. Surface treatment: Surface treatment such as galvanizing or other anti-corrosion treatment is carried out as needed to improve the durability of the wire spacers.Product Application Scenarios

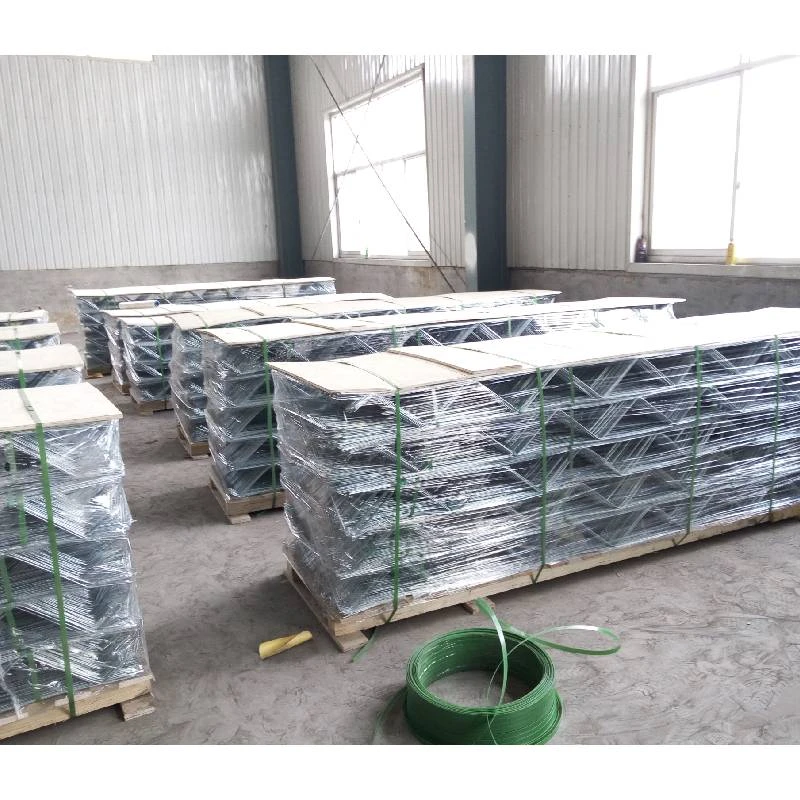

The wire spacers are mainly used in the construction of buildings to provide support for reinforcement mesh and steel bars when laying concrete slabs or formworks. They can be used in various types of building structures, such as houses, bridges, roads, water conservancy projects, etc.

Product Price Advantage

The price of the wire spacers is relatively low, which is an economic solution for building applications. Their simple design and manufacturing process result in lower production costs, thus providing users with competitive prices.

-