Product Introduction

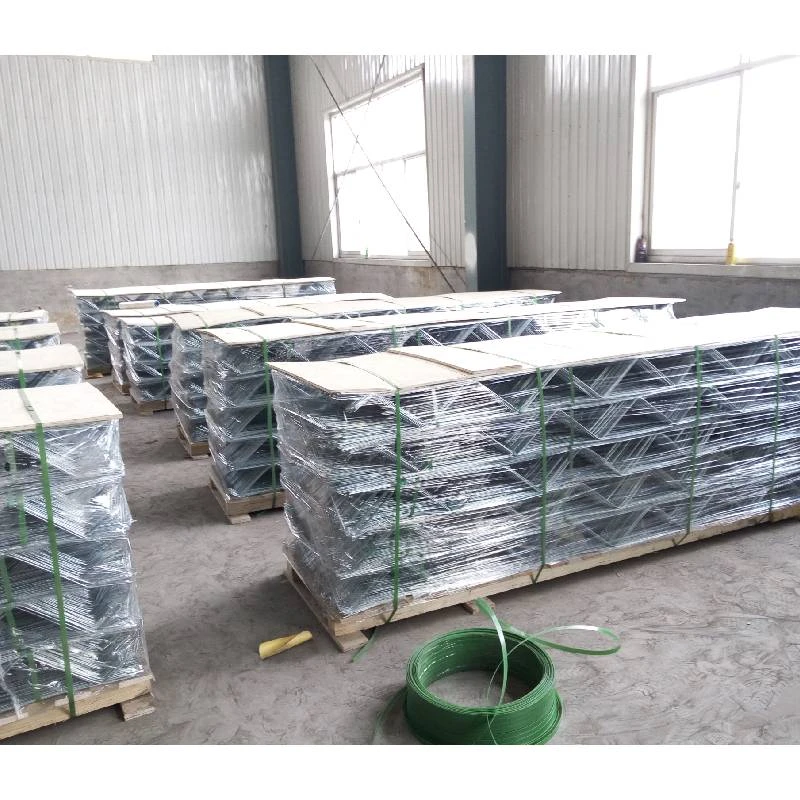

The Stable binder (Bindefix) is a firm element to fasten the rods and stirrups of the concrete reinforcement, that ensures the exact position of the reinforced iron rods, providing a strong non-rigid adhesion. This product, made with special high-strength steel, is packaged in a special package for easy and practical use, but also to ensure its prompt distribution on the working site.

It is manufactured in many standard sizes to cover the widest range of applications. With the traditional iron wire fastening system, it is possible to achieve 160 to 200 bindings in an hour, while the Stable binder makes it possible to achieve 450 to 500 bindings in the same amount of time: therefore saving about 30% on the labor and on the manufactured item.

Easy to fix without the need for tools and without the risk of offcuts our range of stabil binders bindefix ties makes tying cages fast and simple. Offers a 30% reduction in labour over traditional tying methods.

Product Description

Stable binder (Bindefix) is a special binding element designed for fixing the rods and stirrups of concrete reinforcement. It is made of high-strength steel to ensure the strength and reliability of the connection. The binder is designed to provide a strong non-rigid adhesion, ensuring the exact position and stability of the reinforcement rods during concrete pouring. This helps to improve the integrity and stability of the concrete structure, reducing the risk of reinforcement rods shifting or loosening.

Product Application Scenarios

Application industries: Stable binder (Bindefix) is widely used in the construction industry, especially in concrete reinforcement work. It is suitable for use in various construction projects, including buildings, bridges, roads, and infrastructure. The binder is used to fix the reinforcement rods and stirrups in place, ensuring their accurate position and stability.

Product Manufacturing Process

Stable binder (Bindefix) is typically made by forming high-strength steel wire into a specific shape, such as a double hook or a U-shaped bend. The formed steel wire is then treated with a special coating or coating process to provide non-rigid adhesion and protection against rust and corrosion. Finally, the binder is packaged in a special package for easy handling and use on the construction site.

It should be noted that the specific manufacturing process may vary depending on different manufacturers and application requirements. When choosing and using Stable binder (Bindefix), it is recommended to select products that meet relevant standards and quality requirements to ensure the safety and reliability of the connection. At the same time, please follow the manufacturer's instructions and construction specifications for correct installation and use.

Product Parameters

|

Stabil Binders Bindefix Ties |

|||

|

PART CODE |

STIRRUP DIA (mm) |

ROD DIA (mm) |

PACK SIZE |

|

TCWSB06 |

4/5/6 |

6 |

15000 |

|

TCWSB08 |

4/5/6 |

8 |

10000 |

|

TCWSB10 |

5/6/8 |

10 |

11200 |

|

TCWSB12 |

5/6/8 |

12 |

9600 |

|

TCWSB16 |

6/8/10 |

16 |

4000 |

|

TCWSB20 |

6/8/10 |

20 |

4000 |

|

TCWSB25 |

6/8/10 |

25 |

4000 |