Product Description

Sandwich panel anchors are mainly used for carrying the resulting vertical loads from the dead load of the facing layer. Planned or unplanned eccentric loads and horizontal loads due to e.g. wind and temperature deformation should also be considered.

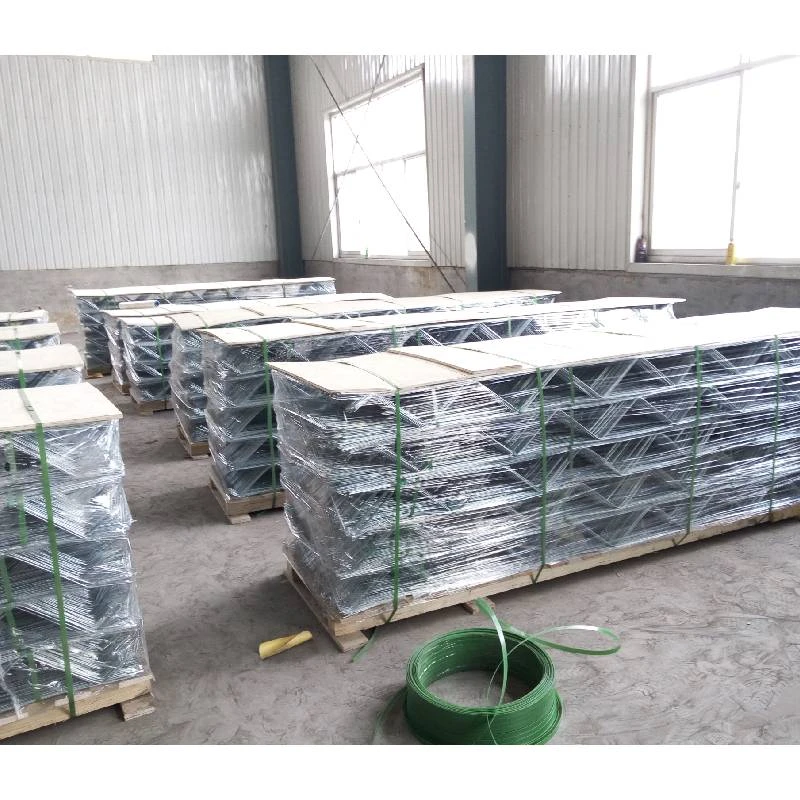

Products made of stainless steel wire, for connecting cladding panels with inner panels in a concrete sandwich wall.

Sandwich panel anchors are used as load bearing anchors. They are V-shaped anchors made of wire stainless steel (AISI316), with wire diameters of 5 mm, 6.5 mm, 8.5 mm and 10 mm. The bent ends ensure anchorage in concrete and to fix the reinforcement bars.

The load on the anchors depends on the dead weight of the façade layer, wind load and the warping caused by the temperature.

Sandwich Panel Anchors are load-bearing anchors used in sandwich panel construction. They are V-shaped anchors made of stainless steel wire (AISI316&304) with wire diameters of 5mm, 6.5mm, 8.5mm, and 10mm. The bent ends of the anchors ensure secure anchoring in concrete and allow for the fixing of reinforcement bars.

Product Advantages

1. High strength: Made of stainless steel wire, they have high strength and corrosion resistance, able to withstand large loads.

2. Easy installation: The V-shaped design and bent ends make installation easy, saving installation time and cost.

3. Multiple size options: They come in different wire diameters to meet the needs of different sandwich panels and load requirements.

4. Concrete anchoring: The bent ends ensure secure anchoring in concrete, providing reliable connection.

5. Reinforcement bar fixing: Can be used to fix reinforcement bars, enhancing the overall stability of the structure.

Product Instructions

1. Installation preparation: Before using the sandwich panel anchors, ensure that the concrete surface is clean and level.

2. Select the appropriate anchor: Choose the appropriate diameter of the sandwich panel anchor based on the thickness and load requirements of the sandwich panel.

3. Installation of anchors: Insert the sandwich panel anchors into the concrete, making sure the bent ends are fully embedded.

4. Fixing of reinforcement bars: If needed, use the sandwich panel anchors to fix the reinforcement bars for enhanced stability.

5. Inspection and acceptance: After installation, inspect the quality of the sandwich panel anchors to ensure they meet the requirements.

The production process of Sandwich Panel Anchors typically involves bending and forming high-strength stainless steel wires into a V-shaped shape to meet the specific requirements of different projects.

Product Application Scenarios

Sandwich Panel Anchors are widely used in various sandwich panel structures, such as exterior walls, interior walls, and ceilings of buildings. They are essential in providing secure anchoring for sandwich panels, ensuring the stability and safety of the overall structure.

Product Price Advantage

Sandwich Panel Anchors are relatively inexpensive, offering a cost-effective solution for anchoring sandwich panels. Their simple design and manufacturing process result in lower production costs, making them more affordable for users.