Product Advantages

1. High strength and corrosion resistance: Made of stainless steel wire, they have high strength and corrosion resistance, able to withstand large loads and resist corrosion to extend their service life.

2. Easy installation: Simple in design and easy to install, requiring no professional skills, reducing construction time and cost.

3. Multiple size options: Available in different wire diameters to meet the requirements of different sandwich panels and load demands.

4. Concrete anchoring: Can be firmly anchored in concrete to provide reliable connection.

5. Improve production efficiency: In the negative production method of sandwich panels, the use of hairpin-anchors can improve production efficiency and reduce construction time and cost.

Instructions

1. Installation preparation: Ensure that the concrete surface is clean and level.

2. Select the appropriate anchor: Choose the appropriate diameter of hairpin-anchors based on the thickness and load requirements of the sandwich panel.

3. Install the anchor: Insert the hairpin-anchors into the wet concrete, making sure the bent ends are fully embedded.

4. Inspection and acceptance: After installation, inspect the quality of the hairpin-anchors to ensure they meet the requirements.

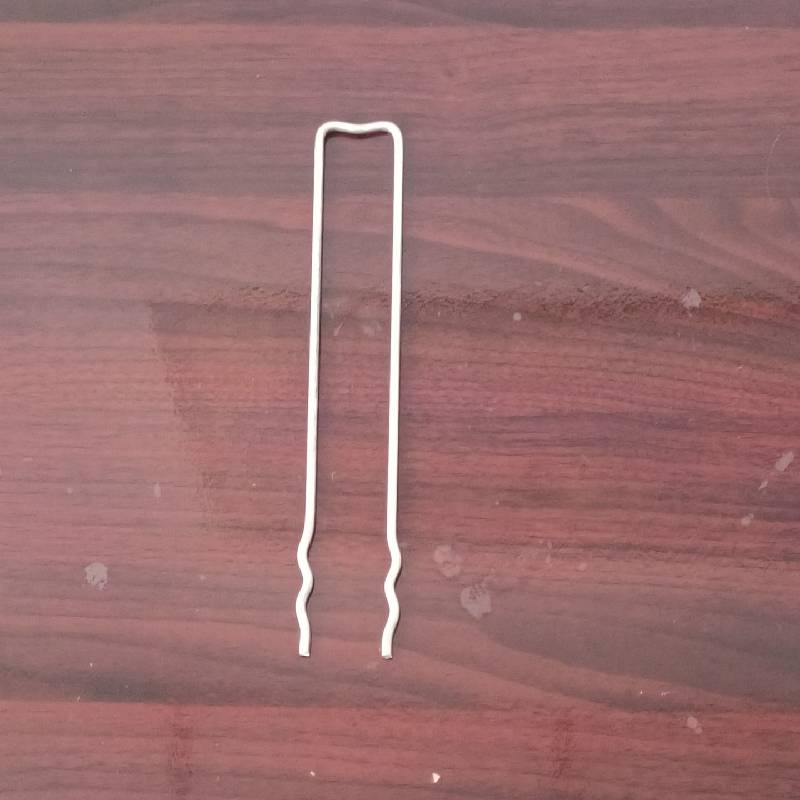

The production process of hairpin-anchors typically involves bending high-strength stainless steel wires into a U-shaped shape to meet the specific requirements of different projects.

Product Application Scenarios

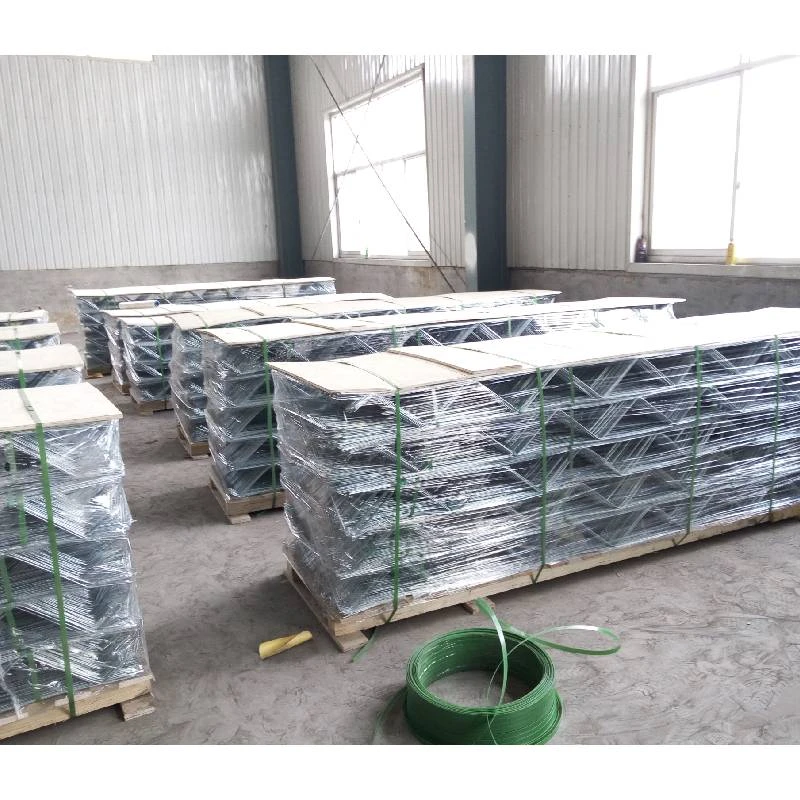

Hairpin-anchors are widely used in various sandwich panel structures, such as exterior walls, interior walls, and ceilings of buildings. They are essential in providing secure anchoring for sandwich panels, ensuring the stability and safety of the overall structure.

Product Price Advantage

Hairpin-anchors are relatively inexpensive, offering a cost-effective solution for anchoring sandwich panels. Their simple design and manufacturing process result in lower production costs, making them more affordable for users.