Product Content

Wires Type :

1.Galvanized wire

2.Black annealed wire

3.PVC coated wire

4.Stainless steel wire,

4.Cooper wire, brass wire.etc

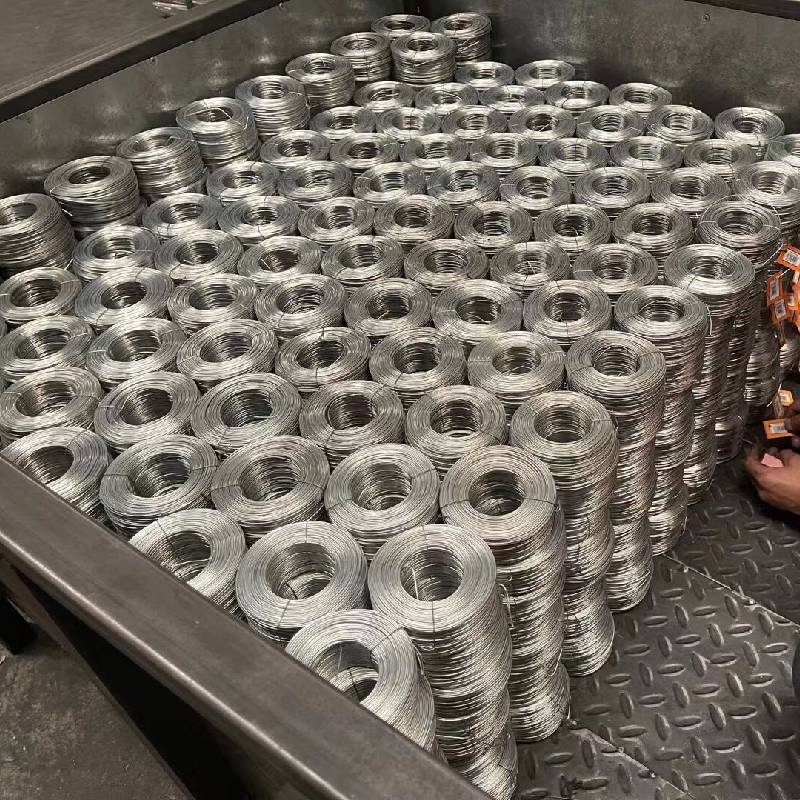

Coil weight: 200g,400g,500g, 1kg, 1.42kg(3.5lbs),5kgs, etc

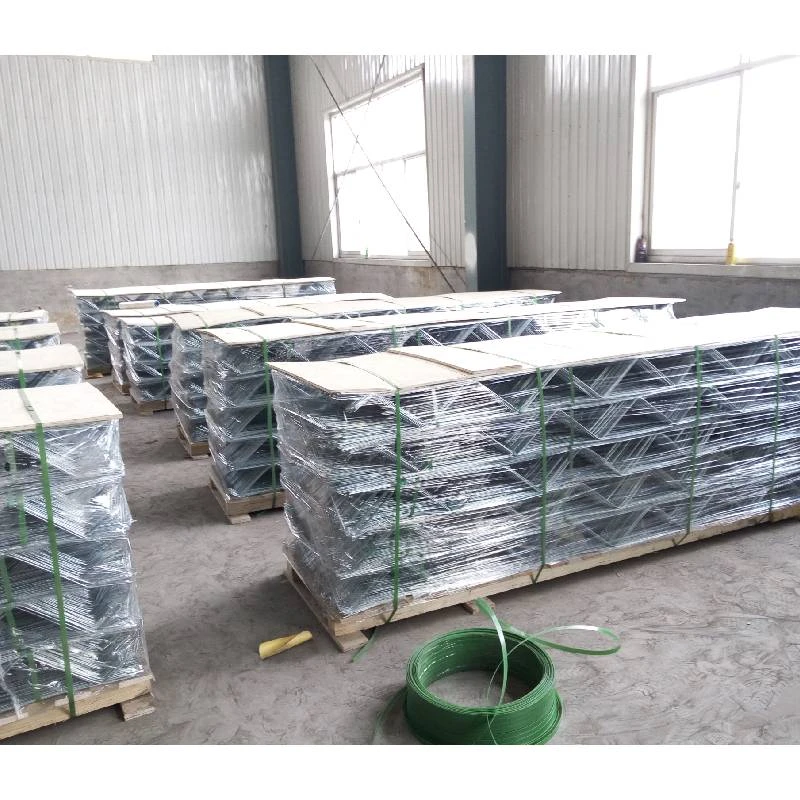

Packing Details: Cartons, Palletised

Delivery Details: Container Seaway

Production Process of rebar tie wire :

Steel rod coil — Wire Drawing — Wire Annealing–Rust Removing–Acid Washing– Boiling– Drying– Zinc Feeding– Wire Coiling.

Product Description

Detailed Description:Rebar tie wire is a type of metal wire used to fix and connect rebars. It is usually made of high-strength steel wire through processes such as drawing, surface treatment, and winding. It has high strength, corrosion resistance, and good flexibility, and is suitable for the binding of rebars in construction engineering, formwork support, and the fixation of other structures. The diameter of the rebar tie wire is usually between 0.5mm and 2.0mm, and the length can be customized according to needs. It can be galvanized to increase corrosion resistance.

Product Application Scenarios

Application Industries:It is mainly used in construction engineering, such as house construction, bridges, roads, tunnels, etc. In these fields, the rebar tie wire is used to fix and connect the rebars to ensure the stability and safety of the structure. It can also be used in horticulture and agriculture, such as fixing fences, enclosures, plant supports, etc.

Product Production Process

Manufacturing Method: The manufacturing of the rebar tie wire usually includes the following steps:

- Wire drawing: The high-strength steel wire is stretched through a wire drawing machine to reduce its diameter to the required size.

- Surface treatment: The drawn steel wire is surface-treated to increase its corrosion resistance and bonding strength with concrete. Common surface treatment methods include galvanizing, coating with epoxy resin, etc.

- Winding into bundles: The surface-treated steel wire is wound into bundles for easy storage, transportation, and use.

Product Advantages

- 10 gauge to 20 gauge diameters.

- 5 lbs./coil standard package.

- Anti-corrosion and rust resistance for durability.

- High tensile strength for stability and reinforcement.

- Ideal for concreting and general construction tying.

- Special discounts for large orders.

- Customized sizes and services are available.

Concrete wire snake spacer

-