Detailed description

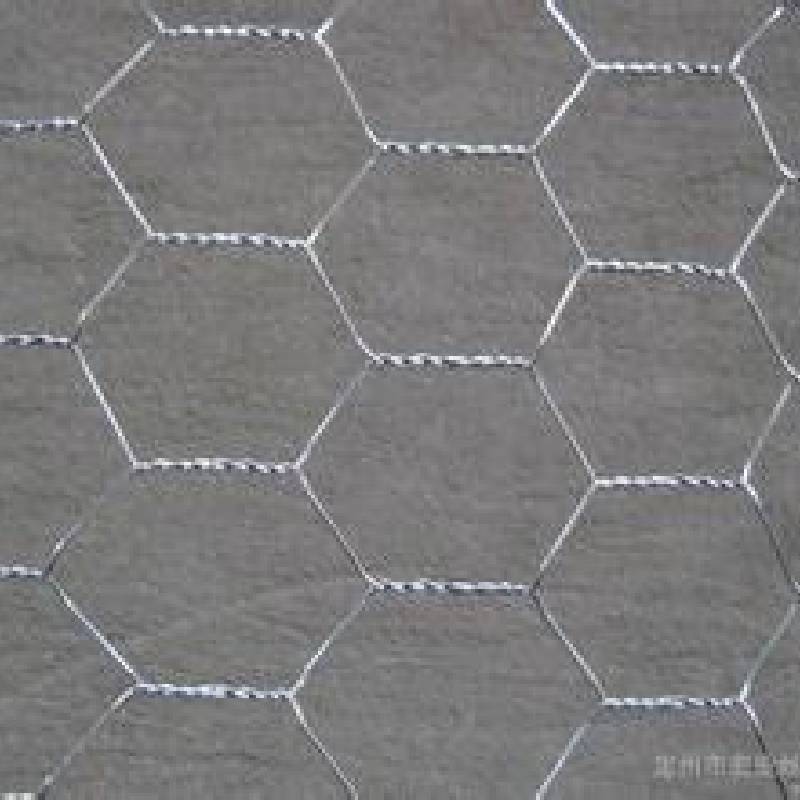

Poultry Netting is a type of metal wire mesh, also known as chicken coop net or hexagonal wire mesh. It is woven from low-carbon steel wire or stainless steel wire to form a hexagonal mesh. This metal wire mesh has the characteristics of corrosion resistance, wear resistance, and high temperature resistance. Its mesh size is usually 1 inch (2.54 cm) or smaller to prevent small animals from escaping. In addition, it has good insulation properties and mechanical strength, and is widely used in construction, agriculture, and industry.

Application industries

Poultry Netting is mainly used in agriculture, horticulture, and poultry farming. In agriculture and horticulture, it can be used to make the support structure of vineyards and orchards, build greenhouses and shades. In poultry farming, it can be used to build chicken coops, rabbit cages, birdhouses, and orchard fences. In addition, it can be used to prevent wild animals from entering gardens, farmland, or yards. In addition, it can be used for screening, filtering, and protecting crops, fruits, and vegetables.

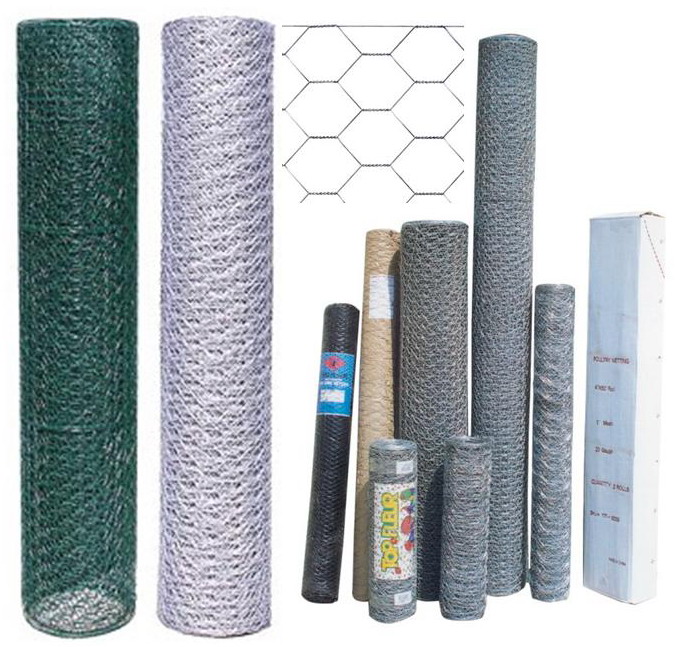

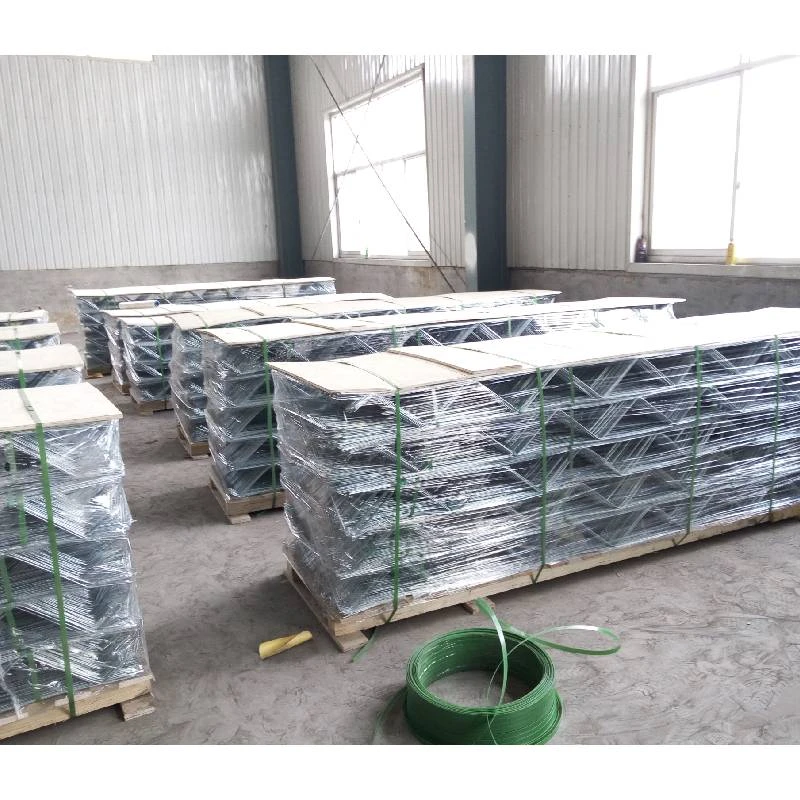

packaging methods

The process of making Poultry Netting usually includes the following steps:

Wire process: First, the wire is surfaceprocess to remove dirt and oxide layers to improve the adhesion between plastic and wire.

Plastic extrusion: PVC plastic particles are heated to a molten state, and the plastic is evenly coated on the wire surface through an extruder.

Cooling and curing: The coated wire is cooled by a cooling device to cure the plastic and tightly bond it to the wire surface.

Cutting and packaging: According to needs, the coated wire is cut into an appropriate length and packaged for sale.It should be noted that the specific manufacturing and packaging methods may vary due to different manufacturers and application requirements. When choosing and using Poultry Netting, it is recommended to select the appropriate specification and model according to the specific application scenario and follow the relevant safety standards and usage instructions.

Specifications

|

Hexagonal Wire Netting |

||||||||

|

Mesh |

Min. Gal.v.G/SQ.M |

Width |

Wire Gauge (BWG) |

|||||

|

Inch |

mm |

Tolerance(mm) |

|

|

|

|||

|

3/8" |

10mm |

±1.0 |

0.7mm - 145 |

2' - 1M |

27, 26, 25, 24, 23 |

|||

|

1/2" |

13mm |

±1.5 |

0.7mm - 95 |

2' - 2M |

25, 24, 23, 22, 21 |

|||

|

5/8" |

16mm |

±2.0 |

0.7mm - 70 |

2' - 2M |

27, 26, 25, 24, 23, 22 |

|||

|

3/4" |

20mm |

±3.0 |

0.7mm - 55 |

2' - 2M |

25, 24, 23, 22, 21, 20, 19 |

|||

|

1" |

25mm |

±3.0 |

0.9mm - 55 |

1' - 2M |

25, 24, 23, 22, 21, 20, 19, 18 |

|||

|

1-1/4" |

31mm |

±4.0 |

9mm - 40 |

1' - 2M |

23, 22, 21, 20, 19, 18 |

|||

|

1-1/2" |

40mm |

±5.0 |

1.0mm - 45 |

1' - 2M |

23, 22, 21, 20, 19, 18 |

|||

|

2" |

50mm |

±6.0 |

1.2mm - 40 |

1' - 2M |

23, 22, 21, 20, 19, 18 |

|||

|

2-1/2" |

65mm |

±7.0 |

1.0mm - 30 |

1' - 2M |

21, 20, 19, 18 |

|||

|

3" |

75mm |

±8.0 |

1.4mm - 30 |

2' - 2M |

20, 19, 18, 17 |

|||

|

4" |

100mm |

±8.0 |

1.6mm - 30 |

2' - 2M |

19, 18, 17, 16 |

|||