Product Introduction

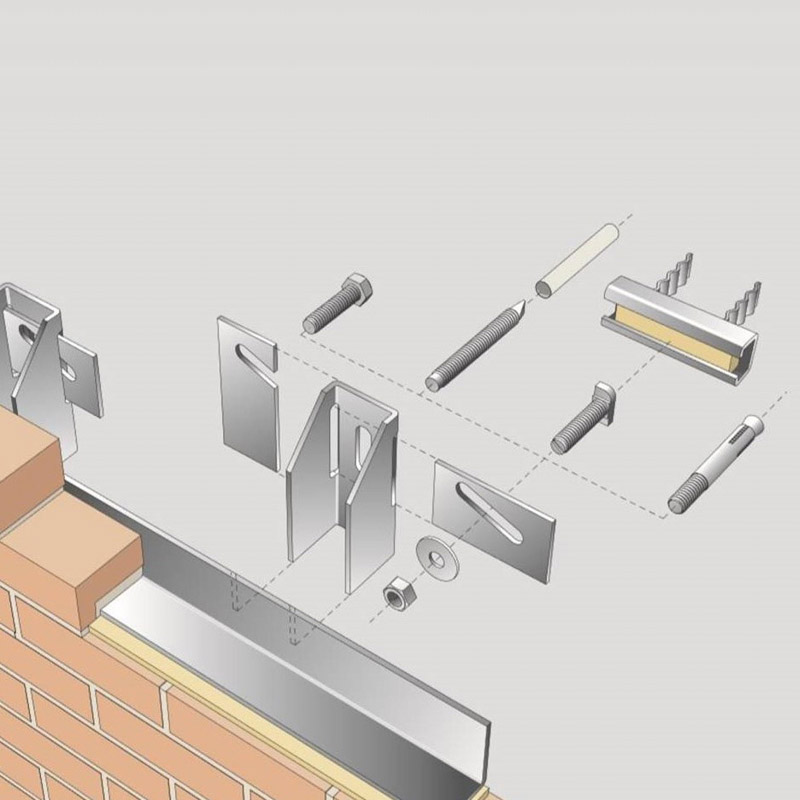

Masonry suport are a stainless steel & galvanized steel system of angles based on special bracets, used to support elevations in horizontal locations of dilatation, long or corner lintels or where there is no foundation for the façade wall. The standard console consists of an angle mounted on one or several bracets. Bracets have different shapes and overhangs matched each time to the structure of the building and are produced in various shapes and overhangs. Our technical office each time adapts them to the construction solutions prevailing at a given facility in such a way as to optimize the costs of mounting the façade.

Welded Masonry Support is a ‘traditional’ rigid masonry support system comprising of fixed brackets welded to a stainless steel angle support shelf.

Structures with brick or stone cladding will usually necessitate the use of a steel support system for the masonry. Frame type, differential movement, type of cladding, masonry load and cavity width all need to be considered when selecting the most appropriate fixing solution.

Bracket Angle masonry Support Systems create a continuous length of angle to support the outer leaf of masonry.

Masonry support is a standard system where the brackets and angles are supplied as separate components.the systems have brackets welded to the angle and are designed to suit the specific cavity width and masonry load of a project.

NOTE: The special shape of bracets practically eliminate thermal bridges during façade assembly to the building’s structure. It also allows to a large extent to minimize the effects of irregular reinforced concrete. Lintels on consoles are used in the following.

Product Description

- Material: Made of stainless steel or galvanized steel, it has corrosion resistance and durability.

- Angle design: Based on a special bracket design, it provides a stable support structure.

- Application scenarios: It is suitable for the expansion of horizontal positions, long or angular lintels, or to support facade walls in the absence of a foundation for the facade.

Product Application Scenarios

- Construction: In construction, it is used to support and fix masonry structures to ensure structural stability and safety.

- Civil engineering: It is used in civil engineering projects such as roads, bridges, and tunnels to provide support and fixation.

- Decorative buildings: In decorative building projects, it is used to fix and support masonry finishes to ensure the decorative effect and structural stability.

Product Manufacturing Process

- Material selection: Select high-quality stainless steel or galvanized steel to ensure its corrosion resistance and durability.

- Processing and forming: Use advanced processing equipment to process the steel into the required angles and shapes.

- Surface treatment: According to needs, surface treatment such as galvanizing, painting, etc. is carried out to improve its corrosion resistance and aesthetics.

- Installation and fixation: Install the bracket in the specified position using bolts, nuts, welding or other fixation methods according to the installation requirements.

Customized production

We can produce customized Masonry support according to customer needs. We have advanced production equipment and a technical team, and can customize production according to customer drawings and requirements. Our Masonry support has the advantages of high strength, corrosion resistance, and durability, and is widely used in various fields. If you have any questions or needs about Masonry support, please feel free to contact us.

Cases

– in corner windows,

– in long openings with a high wall shield,

– in windows where the first layer bricks are laid on the soldier bond

– in levels where horizontal dilation is carried out,

– in elevations made of half-brick.

We can do any size according clients need

|

|