introduzione al prodotto

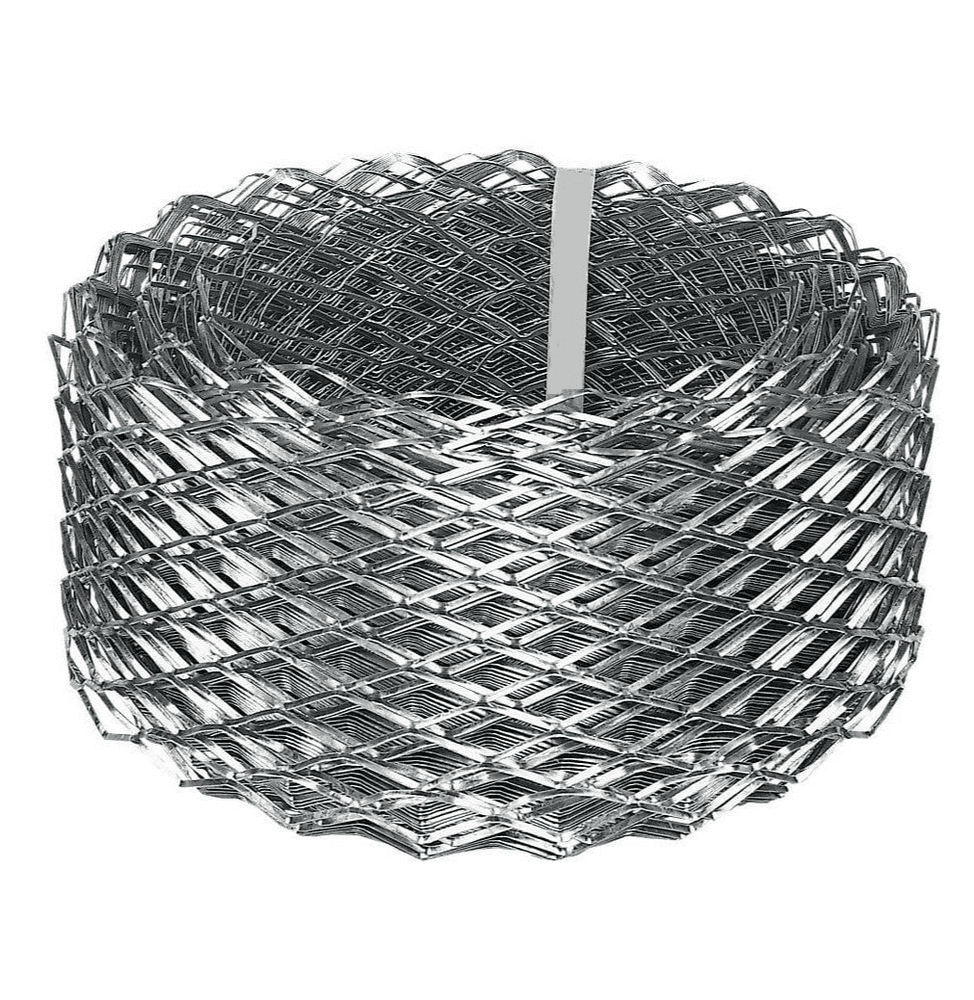

Brick reinforcement mesh is essential reinforcement components for masonry work to provide additional resistance to stresses, vibration and thermal movement of the brick wall. The lowest layer of wire mesh brick wall should be laid over the 1st or 2nd course and at every subsequent 4th course of brickwork. There should be a minimum 150mm lapping where different sections of masonry reinforcement mesh overlap.

Materiale: acciaio zincato, acciaio inossidabile

Larghezza: 65 mm, 100 mm, 175 mm, 225 mm, 300 mm

Lunghezza: 1,2 m, 20 m

Applicazioni

La lamiera stirata viene utilizzata principalmente in lastre di cemento, strade, pavimentazioni, fondazioni, lavori marittimi, camere blindate di banche, lastre divisorie, lavori su blocchi di cemento, grondaie in asfalto, ecc.

Specifiche

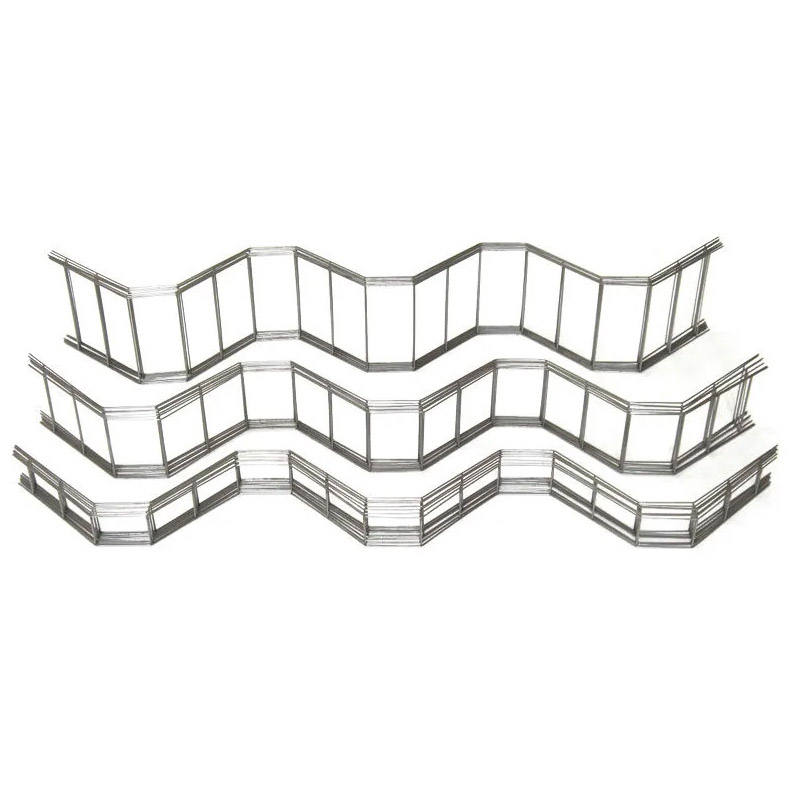

Specifica della rete del muro di mattoni

Larghezza: 65 cm, 100 cm, 150 cm, 200 cm

Lunghezza: 1,2 m, 20 m

Specifica della rete metallica del mattone

Spessore: 0,3-0,6 mm

Dimensione maglia: 12x25 mm

Larghezza rotolo: 65 mm, 75 mm, 100 mm, 175 mm, 225 mm, 300 mm ecc.

Lunghezza del rotolo: 10 m, 30 m, 50 m, 100 m ecc.

Imballaggio: Su cartoni o come vostro requisito.

|

Zincato |

Inossidabile |

Peso normale |

Dimensioni del rotolo |

Consigliato |

|

FLS-01 |

SS |

0.9 |

65 mm x 100 m |

Per pareti da 100 mm |

|

FLS-02 |

SS |

0.9 |

115 mm x 100 m |

Per pareti da 150 mm |

|

FLS-03 |

SS |

0.9 |

175 mm x 100 m |

Per pareti da 200 mm |

|

FLS-04 |

SS |

0.9 |

225 mm x 100 m |

Per pareti da 250 mm |

Descrizione della rete di mattoni

Brick reinforcement mesh is easy to handle, and when laid embedded in the mortar joint between brickwork or blockwork courses, it forms an integral structure with excellent tensile strength. This added strength improves the wall’s resistance to movement, vibrations, and thermal expansion, making it a reliable component for long-lasting structures.

The available range of brick reinforcing coil is suitable for most wall thicknesses. It should be laid on the mortar bed with a 25mm clearance from the outer face of the wall and overlapped by at least 75mm where lengths join. For most masonry applications, installing the mesh in every third course is generally sufficient to meet reinforcement needs.

Installazione della rete di mattoni:

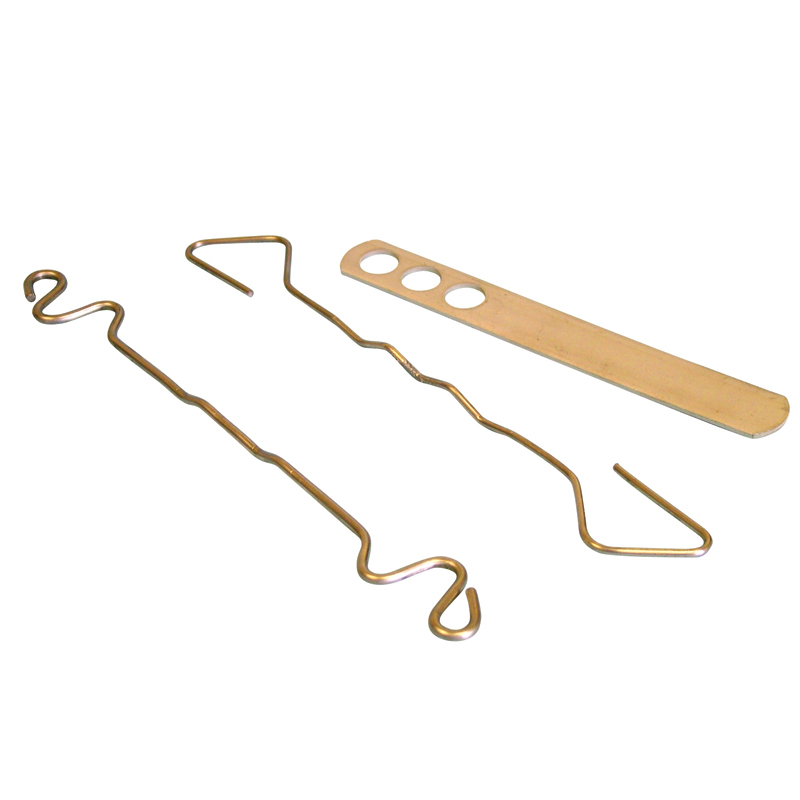

Fix the masonry reinforcement mesh into mortar between brick courses, maintaining a 25mm clearance from the brickwork face. Ensure a minimum 75mm overlap at all joints. For general reinforcement, the mesh should be laid in every third course of brick wall mesh construction.

Applicazioni della rete di mattoni:

Our wire mesh brick wall products are widely used in concrete slabs, roadbeds, paving, foundation support, marine projects, bank vaults, partition slabs, concrete blockwork, asphalt guttering, and more. This versatile brick mesh wall solution improves overall structural stability across various industries.

As a professional stainless steel mesh supplier with advanced testing equipment and strong technical capability, we offer high-quality reinforcement products with competitive prices and stylish design. Our products are trusted across the masonry, chemical, and machinery industries, meeting the ever-evolving needs of our clients. We warmly welcome new and long-term partners to collaborate with us for mutual growth and success.

Where Is Brick Reinforcement Mesh Used?

The use of brick reinforcement mesh spans a wide range of construction applications, especially in masonry work where added structural strength and crack resistance are crucial. This mesh is typically embedded between courses of brickwork or blockwork to form an integral system that resists shifting, cracking, and settling. Its importance becomes especially clear in projects demanding long-lasting, crack-free walls — from residential housing developments to large-scale industrial or civic structures.

One of the most common applications is in constructing brick mesh wall systems. These walls are typically subjected to both vertical and lateral loads. When brick reinforcement mesh is laid within the mortar joints, it distributes stress more evenly across the surface, greatly reducing the likelihood of thermal cracking or displacement caused by structural movement. This feature is especially valued in seismically active regions or in buildings with expansive facades.

Another common use of brick wire mesh is in garden retaining walls and cavity walls. Here, the mesh acts as a hidden yet crucial layer that ties together different components of the structure. It’s especially helpful when laying hollow bricks or lightweight blocks, which may otherwise lack the interlocking strength of solid bricks.

At Shijiazhuang TangChao Metal Products Co., Ltd., we supply a wide variety of brick reinforcement mesh types, including galvanized and stainless steel options. These products are made using high-precision equipment imported from Germany and Korea, allowing us to meet the diverse needs of global customers. Our 7,000 m² facility and annual production capacity of 22 million RMB enable fast turnaround and consistent quality assurance.

Our masonry reinforcement mesh has been widely adopted across North America, Europe, and the Middle East, where it is used in everything from residential wall partitions to commercial firewalls and industrial support structures. Our technical team works closely with clients to ensure mesh dimensions, wire thickness, and material types meet the engineering demands of each project.

In short, brick reinforcement mesh is not merely a support product—it’s a foundational material used wherever long-term durability, safety, and structural consistency are priorities. From small home renovations to massive infrastructure builds, this mesh proves its value in performance and peace of mind.

Why Is Brick Reinforcement Mesh Essential in Construction?

In modern masonry construction, builders are expected to deliver both durability and cost-efficiency. Brick reinforcement mesh fulfills both criteria, making it an indispensable tool for professional contractors and civil engineers. Its ability to improve load distribution and prevent wall deformation under stress makes it a core element in both traditional and contemporary building practices.

When constructing high-rise buildings, load-bearing walls, or extended facades, the integration of brick wall reinforcement mesh becomes necessary to maintain wall integrity. Without it, even well-laid masonry can suffer from cracking due to thermal expansion, ground settlement, or vibrations. The mesh acts as a reinforcement layer, securing the mortar joint while allowing the structure a degree of flexible movement to absorb tension.

Another significant application is in lintel zones and wall corners—areas most susceptible to cracking. By installing brick reinforcing coil or stainless steel brick reinforcement mesh, builders ensure that even the most vulnerable parts of the structure are secured. In this way, the mesh not only extends the lifespan of the wall but also reduces future maintenance costs.

At Shijiazhuang TangChao Metal Products Co., Ltd., our commitment to quality and innovation has made our brick reinforcement mesh a preferred choice for both domestic and overseas projects. With equipment imported from Taiwan and a strong R&D team of 30 professionals, we produce advanced reinforcement solutions like brickwork reinforcement mesh that exceed industry standards. Our mesh is produced using high-tensile wires and comes in rolls or coils that are easy to handle and install.

Our clients in the United States, Canada, and the UAE frequently use our mesh in large-scale housing developments and government infrastructure projects. These clients value the reliability and uniformity of our products, especially where consistent wall strength is a strict requirement.

Moreover, brick reinforcement mesh contributes to a project’s compliance with modern building codes and green construction standards. It reduces the need for additional steel bars or overly thick walls, saving materials while improving safety. It's a simple yet impactful solution for any structure that relies on brick or block construction.

What Are the Benefits of Brick Reinforcement Mesh?

The benefits of brick reinforcement mesh go far beyond the visible surface. While it may be hidden within the layers of a wall, the impact it has on performance, safety, and efficiency is tangible. Builders, architects, and property owners who choose to integrate this mesh into their projects enjoy long-term structural advantages that are hard to replicate with traditional methods.

Superior Crack Control

The most obvious benefit is the significant reduction in wall cracking. By laying brick wall mesh between courses of bricks or blocks, it acts as a tensile reinforcer that absorbs stresses caused by temperature changes, load movement, or ground shifting. This prevents unsightly and potentially dangerous fissures from forming in the wall.

Enhanced Durability and Strength

With wire mesh masonry wall reinforcements, walls gain extra load-bearing capacity and improved resilience under compression and lateral pressure. This is especially beneficial for retaining walls, parapets, and multi-story buildings where structural stress is common.

Versatility Across Wall Types

Whether you're building a solid brick wall, a cavity wall, or a concrete block wall, galvanised reinforcement coil and stainless steel variants are available in various widths and diameters to match project specifications. Our fabbrica di rete metallica also supports custom sizes for niche architectural applications.

Cost-Effective and Easy to Install

Brick reinforcement mesh is lightweight and requires no special tools to install. This speeds up construction timelines and reduces labor costs. Combined with its low maintenance needs, the product offers a high return on investment over time.

Global-Quality Manufacturing

At Shijiazhuang TangChao Metal Products Co., Ltd., our advanced manufacturing equipment and strict quality control ensure uniform thickness, smooth finishes, and long-lasting zinc or stainless coatings. Our products are tested to international standards and have earned the trust of clients across more than 15 countries.

Clients using our brick reinforcement wire in places like Australia and Singapore have reported not only improved construction quality but also better customer satisfaction and fewer post-construction complaints. This aligns with our core mission—to improve product performance through innovation, and to serve global markets with dependable, quality-assured building materials.

In summary, the benefits of brick reinforcement mesh are clear: reduced cracking, longer wall life, lower costs, and faster builds. It’s not just a supporting material—it’s a smart investment in structural reliability.