Industry Applications

High-Rib Mesh is primarily used in construction joint applications but it is also used to form wall, beam &column surfaces and slabs soffits, where the formed surface will not be seen.

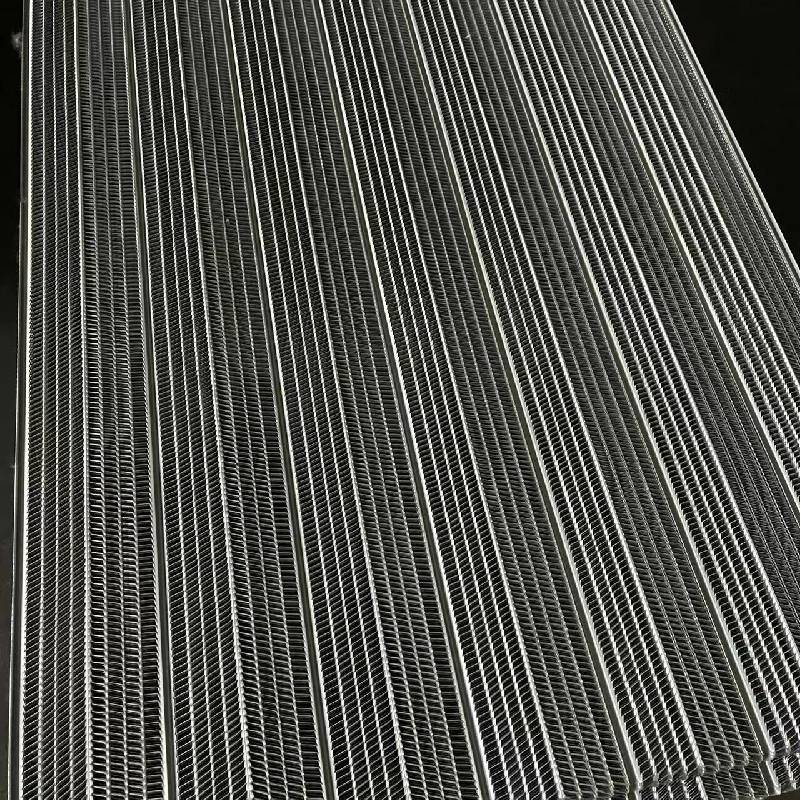

A High-Rib Metal Lath with a herringbone mesh pattern and seven deep longitudinal solid steel ribs providing superior strength and exceptional rigidity. The heavy ribs enable use on ceiling or wall spans at 24 compliant to Table 3 of ASTM C1063. This excellent product is also used on 2 stud-less partitions and as reinforcement for concrete floor and roof slabs.

Manufacturing Method

The manufacturing of High-Rib Lath Mesh typically involves the following steps:

Wire weaving: High-strength steel wire is woven into a mesh structure using weaving machines to form the ribs and open mesh profile.

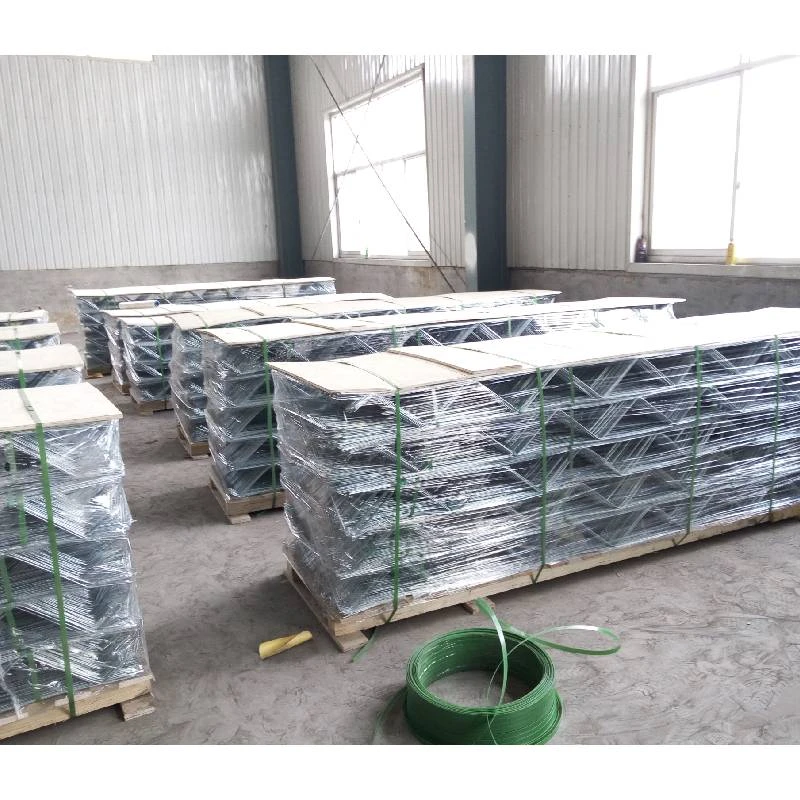

Coating: To enhance corrosion resistance and service life, the woven mesh is often coated with zinc or other protective coatings.

Cutting and forming: The coated mesh is cut and formed to the required dimensions and shapes according to specific project requirements.

Applications

High-Rib Lath Mesh is widely used in the construction industry, especially in concrete formwork. It provides a stable support structure for pouring concrete, ensuring accurate dimensions and uniform distribution. In addition, High-Rib Lath Mesh is also used in infrastructure projects, such as road and bridge construction, as well as in industrial facilities.

precautionary note

It's important to note that the manufacturing method may vary among different manufacturers. When selecting and using High-Rib Lath Mesh, it's advisable to choose the appropriate size and specification based on the specific application and follow relevant safety standards and installation guidelines.