- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 12, 2025 15:27

Back to list

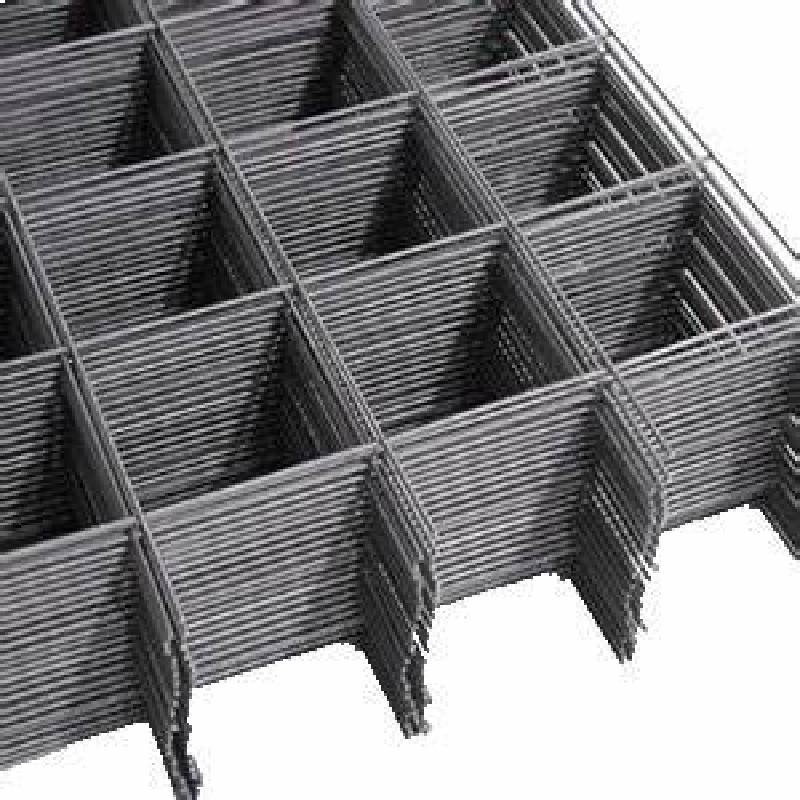

Welded wire mesh

Welded wire mesh manufacturers play a pivotal role in many industries, providing the backbone for construction, agriculture, and manufacturing sectors through durable and versatile products. In the realm of construction, welded wire mesh is indispensable for reinforcing concrete, creating security barriers, and supporting structural integrity. The unique blend of strength and flexibility makes it an essential material used in high-stress environments.

In the agricultural sector, welded wire mesh serves purposes such as fencing for livestock, protecting crops, and infrastructure support for greenhouses. Manufacturers who understand the diverse needs of agriculture provide meshes that offer durability against animal impact and are resistant to corrosion despite heavy exposure to outdoor elements. Coatings such as galvanized or PVC can enhance durability, making these meshes suitable for extended use in harsh environments. For manufacturing applications, where welded wire mesh might serve as machine guards or storage enclosures, manufacturers must ensure their products are not only robust but versatile enough to accommodate specific client demands. This versatility often requires customization capabilities, where manufacturers can alter design specifications to meet personalized requirements without compromising on quality. Manufacturers of welded wire mesh who focus on continuous improvement, sustainability, and customer service often stand out in this competitive field. Implementing sustainable practices, such as using recyclable materials, reduces environmental impact and aligns the manufacturer with globally growing expectations for eco-friendliness. In addition, excellent customer service, which includes guidance during product selection and after-sales support, significantly enhances customer satisfaction, encouraging repeat business and client loyalty. To maximize the impact of their online presence for SEO, manufacturers should ensure that their websites provide comprehensive product descriptions, clear images, and detailed specifications. Regularly updated content such as blogs, guides on application techniques, and industry news can position the website as a valuable resource, encouraging more traffic and converting visitors into customers. Accumulating backlinks from authoritative websites and engaging on relevant industry forums or social media platforms can further enhance online authority and trustworthiness. In summary, the best welded wire mesh manufacturers are those that combine high-quality materials, skilled craftsmanship, proven expertise, and a dedication to customer satisfaction. These attributes not only ensure superior products but also establish a manufacturer's reputation as a reliable partner in every project, big or small. For businesses looking to integrate welded wire mesh into their projects, prioritizing these factors can lead to successful outcomes and sustained success.

In the agricultural sector, welded wire mesh serves purposes such as fencing for livestock, protecting crops, and infrastructure support for greenhouses. Manufacturers who understand the diverse needs of agriculture provide meshes that offer durability against animal impact and are resistant to corrosion despite heavy exposure to outdoor elements. Coatings such as galvanized or PVC can enhance durability, making these meshes suitable for extended use in harsh environments. For manufacturing applications, where welded wire mesh might serve as machine guards or storage enclosures, manufacturers must ensure their products are not only robust but versatile enough to accommodate specific client demands. This versatility often requires customization capabilities, where manufacturers can alter design specifications to meet personalized requirements without compromising on quality. Manufacturers of welded wire mesh who focus on continuous improvement, sustainability, and customer service often stand out in this competitive field. Implementing sustainable practices, such as using recyclable materials, reduces environmental impact and aligns the manufacturer with globally growing expectations for eco-friendliness. In addition, excellent customer service, which includes guidance during product selection and after-sales support, significantly enhances customer satisfaction, encouraging repeat business and client loyalty. To maximize the impact of their online presence for SEO, manufacturers should ensure that their websites provide comprehensive product descriptions, clear images, and detailed specifications. Regularly updated content such as blogs, guides on application techniques, and industry news can position the website as a valuable resource, encouraging more traffic and converting visitors into customers. Accumulating backlinks from authoritative websites and engaging on relevant industry forums or social media platforms can further enhance online authority and trustworthiness. In summary, the best welded wire mesh manufacturers are those that combine high-quality materials, skilled craftsmanship, proven expertise, and a dedication to customer satisfaction. These attributes not only ensure superior products but also establish a manufacturer's reputation as a reliable partner in every project, big or small. For businesses looking to integrate welded wire mesh into their projects, prioritizing these factors can lead to successful outcomes and sustained success.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025