- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 16, 2025 10:55

Back to list

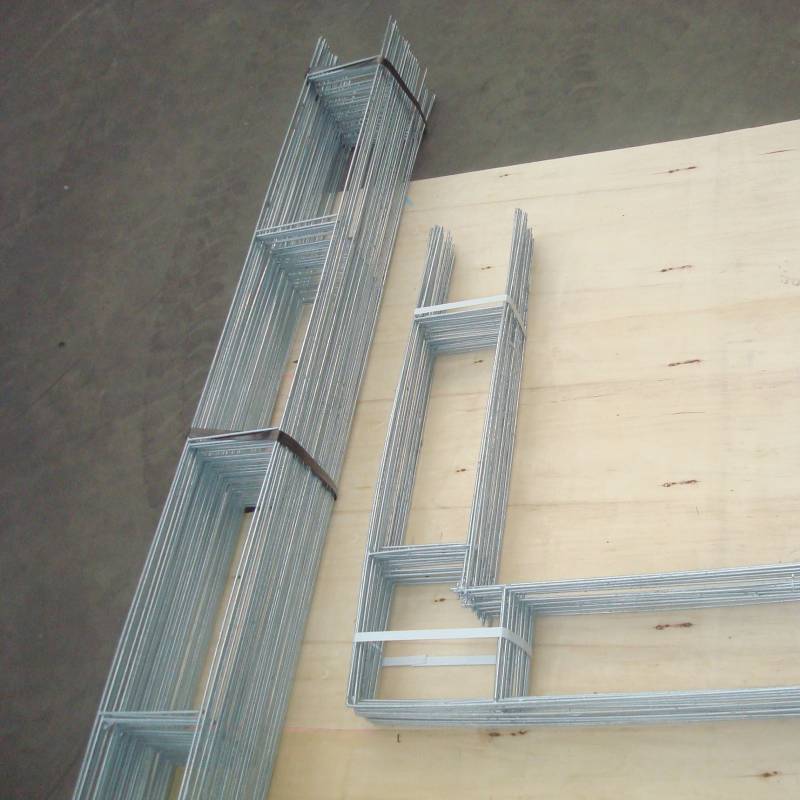

plastering metal corner bead

Modern construction techniques have seen a remarkable evolution, and part of this evolution involves the innovative use of materials such as PVC render beads. Not only are these components vital for achieving smooth, aesthetically pleasing surfaces, but they also confer numerous functional advantages that enhance durability. For professionals in the construction industry or even avid DIY enthusiasts, understanding the nuances of PVC render beads can significantly impact the quality of any rendering project.

Considering longevity, PVC render beads exhibit exceptional endurance. Unlike metals that may succumb to dents and deformations, PVC absorbs impact and reverts to its original shape, mitigating potential repairs. This inherent resilience translates to long-term cost savings for property owners, as replacements and refurbishments are vastly reduced, making PVC render beads a cost-effective long-term solution. From a sustainability perspective, PVC is recyclable, aligning with contemporary construction's emphasis on eco-friendly practices. The ability to recycle unused and old beads reduces landfill waste and conserves resources, further bolstering the environmental responsibility of developers and builders. Moreover, the production of PVC render beads is energy-efficient, resulting in a lower carbon footprint compared to traditional materials. Installation-wise, the process is streamlined thanks to the pre-formed profiles of PVC render beads, which simplify alignment with the surfaces being rendered. This ease not only enhances accuracy but also reduces labor costs and construction time, enabling faster project completion. Whether for new builds or refurbishment projects, the utilization of PVC render beads leads to professional finishes that meet both aesthetic and structural criteria. In conclusion, PVC render beads are an essential asset in modern construction, offering a synergistic blend of durability, safety, and eco-friendliness. Their versatile nature satisfies diverse architectural demands while simultaneously providing significant economic and environmental advantages. For anyone embarking on a rendering project, PVC render beads should be considered indispensable, promising not only to meet but exceed current construction standards in quality and sustainability.

Considering longevity, PVC render beads exhibit exceptional endurance. Unlike metals that may succumb to dents and deformations, PVC absorbs impact and reverts to its original shape, mitigating potential repairs. This inherent resilience translates to long-term cost savings for property owners, as replacements and refurbishments are vastly reduced, making PVC render beads a cost-effective long-term solution. From a sustainability perspective, PVC is recyclable, aligning with contemporary construction's emphasis on eco-friendly practices. The ability to recycle unused and old beads reduces landfill waste and conserves resources, further bolstering the environmental responsibility of developers and builders. Moreover, the production of PVC render beads is energy-efficient, resulting in a lower carbon footprint compared to traditional materials. Installation-wise, the process is streamlined thanks to the pre-formed profiles of PVC render beads, which simplify alignment with the surfaces being rendered. This ease not only enhances accuracy but also reduces labor costs and construction time, enabling faster project completion. Whether for new builds or refurbishment projects, the utilization of PVC render beads leads to professional finishes that meet both aesthetic and structural criteria. In conclusion, PVC render beads are an essential asset in modern construction, offering a synergistic blend of durability, safety, and eco-friendliness. Their versatile nature satisfies diverse architectural demands while simultaneously providing significant economic and environmental advantages. For anyone embarking on a rendering project, PVC render beads should be considered indispensable, promising not only to meet but exceed current construction standards in quality and sustainability.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025