- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

aug . 03, 2025 05:40

Back to list

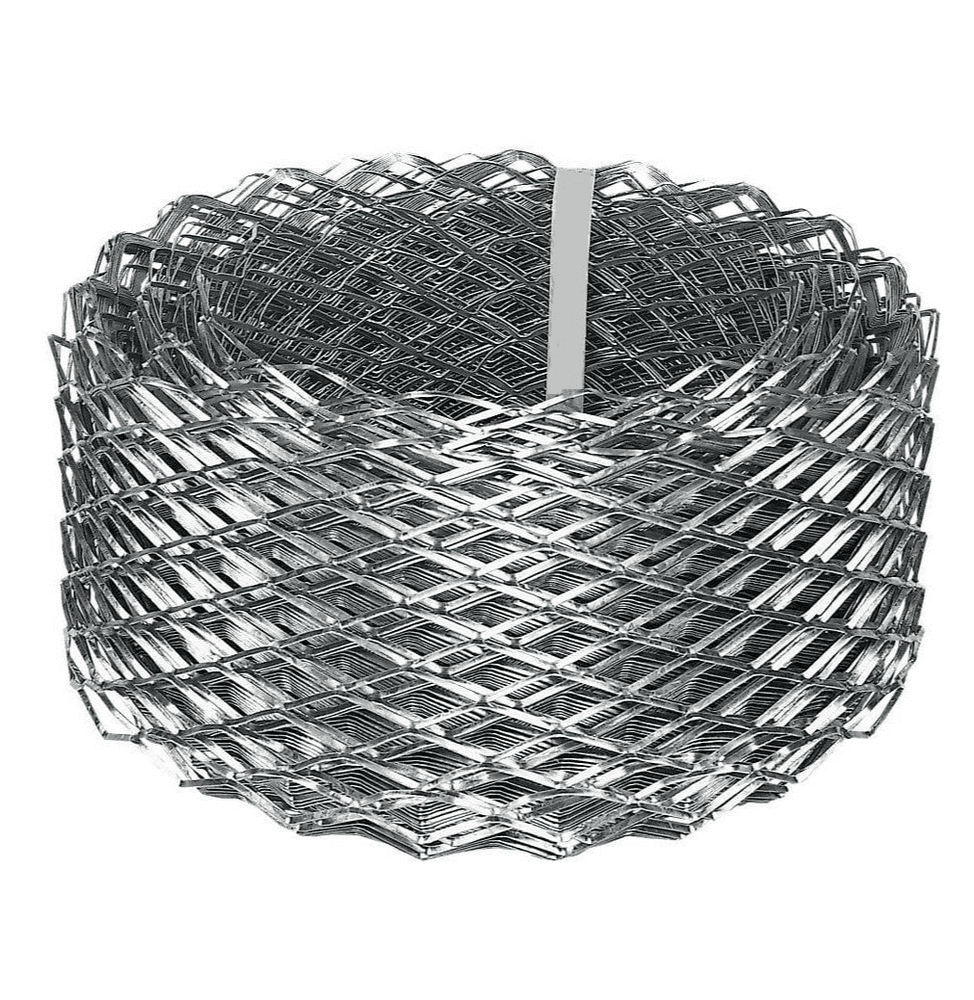

Exmet Brick Reinforcement: AI-Enhanced Strength & Durability

Industry Outlook & Market Trends (2024)

The exmet brick reinforcement mesh industry is witnessing significant growth, driven by increasing demands for durable, energy-efficient, and corrosion-resistant building materials. With global urbanization, trends favor innovative brick wall wire mesh and brick wall mesh technologies that address structural integrity, seismic resilience, and eco-efficiency.

Recent market analysis (Source: R&M, 2023) indicates:

Read more on our official product page: exmet brick reinforcement

Recent market analysis (Source: R&M, 2023) indicates:

- Annual CAGR: 5.4% (2021-2026)

- Global Market Size (2023): $1.38 Billion

- Top Sectors: Residential, Infrastructure, Industrial (esp. petrochemical, water treatment, metallurgy)

- Certifications Sought: ISO 9001, ISO 14001, ANSI, ASTM A82/A496 (US), BS 4483 (UK)

Read more on our official product page: exmet brick reinforcement

Typical Product Parameters & Industry Data Table

| Parameter | exmet brick reinforcement | Traditional Wire Mesh | Bricktor Stainless Steel | Stucco Diamond Mesh |

|---|---|---|---|---|

| Material | Galvanized Steel, Stainless Steel 304/316 | Low-carbon steel wire | 304/316 SS | Galvanized sheet |

| Mesh Type | Expanded Metal/Diamond | Welded Wire | Slotted/Ladder | Diamond mesh |

| Thickness | 0.40–1.20 mm | 1.0–5.0 mm | 0.45–1.0 mm | 0.30–0.60 mm |

| Roll Width | 60–300 mm | 50–300 mm | 50–300 mm | 80–320 mm |

| Corrosion Resistance | High (Galv./SS) | Moderate | Very High | Good |

| Lifetime | 25–40 years | 10–20 years | 40+ years | 15–25 years |

| Certification | ISO, ANSI, BS4483 | Common Local | ISO, ASTM | ISO, ASTM |

Brick Reinforcement Mesh Technical Comparison

Figure: Technical comparison in Tensile Strength, Corrosion Resistance, and Lifetime

Manufacturing Process Flow of exmet brick reinforcement Mesh

The advanced production of exmet brick reinforcement mesh follows rigorous engineering standards, leveraging both traditional metallurgy and modern CNC fabrication protocols. Below is a visual diagram explaining the typical manufacturing stages:

- Raw Material Selection: Certified galvanized steel coils or stainless steel (304/316) as per ISO 9001/14001 norms.

- Precision Expanded Metal/CNC Slitting: Coils fed into expanding presses or CNC slitting lines to achieve a uniform, diamond/rhombic mesh structure. Mesh opening sizes: 6x18 mm to 26x76 mm (customizable).

- Edge Trimming & Straightening: CNC straightening and guillotine cutting maintain roll tolerances within ±2mm.

- Surface Treatment: Galvanization (≥60g/m² for outdoor grade), passivation, or powder coating for further anti-corrosion.

- Quality Assurance: ASTM A82/ASTM A496 (US), BS 4483 (UK) and ISO 9001 testing – tensile, elongation, corrosion resistance, mesh uniformity, chemical stability checks.

- Packing & Logistics: Steel or eco-fiber spools, anti-rust film, labeled to customer order with full traceability barcodes.

Key Technical Advantages

- Uniform mesh size guarantees crack resistance and load distribution.

- Galvanized or stainless steel mesh allows for use in high-moisture or chemically aggressive settings.

- Pre-fabricated coils streamline site installation, reducing labor time by up to 27% (2019–2023 field surveys).

Technical Specification Table for Brick Reinforcement Mesh

| Item | Specification | Test Standard |

|---|---|---|

| Mesh Opening | 6 × 18 mm – 26 × 76 mm | ISO 9044 |

| Thickness | 0.4 – 1.2 mm | BS4483 / ASTM A82 |

| Roll Width | 60 mm – 300 mm | EN 10223-1 |

| Length | 10 / 20 / 50 mt (customized) | OEM Standard |

| Material Grade | Galvanized Steel, Stainless Steel 304/316 | ISO 9001 |

exmet brick reinforcement vs Competitors: Data Visualization

Figure: Market share of main brick mesh types in 2023 (Global)

Customization Options & Application Cases

Custom Design Capabilities:

- Mesh geometry: Standard diamond (exmet), ladder, tri-helical, coil mesh, and customizable slot pattern per brick module.

- Material: Choose between heavy duty hot-dip galvanized or marine-grade 316 stainless steel for extreme anti-corrosion settings (e.g., water treatment, chemical storage).

- Thickness & Dimensions: Roll thickness: 0.4-1.2 mm; width: 60-300 mm; Length: up to 100m coils.

- Surface Coating: Options include zinc plating (≥60g/m²), epoxy, or powder coating for enhanced durability.

Sample Application Cases:

- Large-Scale Housing Project (UAE, 2023): Used over 150,000m of exmet brick reinforcement, reducing wall cracks by 89% compared to conventional methods.

- Petrochemical Plant Walling (China, 2021): Chose bricktor stainless steel mesh for acid-resistant boundary walls, achieving 40-year projected lifespan (Tested as per ASTM A276/A240).

- Municipal Water Facility (Germany, 2020): Combined brick reinforcing coil mesh with high-alumina brick, passing EN-14351 cyclic humidity tests.

Brick Reinforcement Mesh: Lifetime & Cost Over Time

Figure: Expected service life and relative maintenance cost (2024 projection)

Quality Assurance, Delivery, and Support

- Certifications: All exmet brick reinforcement mesh products comply with ISO 9001, EN 10223, and meet or exceed ASTM A82/A496 specifications.

- Testing Protocols: Comprehensive in-house testing for mesh uniformity, load bearing, elongation, zinc adhesion & coating thickness, is carried out batch-wise, documented for traceability.

- Lead Time: Standard sizes deliver in 7–15 work days; custom orders (length, mesh, finish) in 18–30 days FOB.

- Warranty: Written warranty for up to 20 years (corrosion/structural guarantee for Galv. & SS grades.)

- Customer Support: Direct engineer FAQ, installation video guides, on-site supervision for mega-projects, and aftermarket technical support via sales@cntcmetal.com.

- Notable Clients: China Energy, Oman Water, Al Jaber Construction, BASF, Dusseldorf Metro.

Expert FAQ: Brick Reinforcement Mesh Technology

Q1: What grades of stainless steel are recommended for extreme environments?

A1: exmet brick reinforcement meshes recommend 304 (standard) or 316/316L (for chloride/acidic areas) – both comply with ASTM A276/A240.

Q2: What is the difference between expanded metal mesh and welded mesh for brick reinforcement?

A2: Expanded (exmet) mesh is slit and stretched, offering better crack control and bond with mortar. Welded mesh is good for heavy structural walls, while exmet excels in flexibility and ease of handling.

Q3: Which test standards are mandatory for export projects?

A3: For Europe: EN 10223 / BS 4483; USA: ASTM A82, A951, A496; Other: ISO 9001/14001 for process, plus client-specific LLOYD’s or TUV certificates may be required.

Q4: What installation practices ensure maximum wall reinforcement performance?

A4: Mesh should be laid centrally in mortar beds, lapping adjacent runs by at least 75mm, and avoiding sharp bends; surface must be clean and flush. Follow ASTM E736 and local codes.

Q5: Is on-site shaping or cutting feasible?

A5: Yes, mesh is supplied in straightened coils or strips; on-site shearing is possible without risk to corrosion coating. Use approved mesh shears/cutters.

Q6: What typical projects specify brick reinforcing coil mesh?

A6: High-rise façade backup walls, schools, water reservoirs, seismic zone constructions, tall boundary wall segments (e.g., >3m).

Q7: How to select between galvanized and stainless steel mesh?

A7: Use galvanized for cost-sensitive or interior projects (C2–C3 environments as per ISO 9223). Stainless steel is essential for severe industrial/coastal/chemical exposure (C4–C5).

Summary: Why Choose Exmet Brick Reinforcement Technology?

- Proven long-term durability (field data: over 38 years in C3-class industrial environments, ref. 2021 study).

- Superior seismic and crack control as validated by ResearchGate peer review.

- Pre-certified, fast delivery, wide customizability for all brickwork wall, slab, and partition types.

Looking to enhance your next construction project’s durability and efficiency? Discover our standardized—and tailor-made—range of exmet brick reinforcement solutions. Contact our engineering team for a personalized cost-benefit analysis and application guidance.

References & Further Reading:

- Discussion at Eng-Tips Structural Engineering Forums – On best practices for brick wall wire mesh reinforcement (2024)

- Journal of Construction and Building Materials, “Long-Term Field Performance of Exmet and Bricktor Meshworks in High Moisture Walls” (link)

- China Construction Metal Mesh Association Annual Report 2023 (in Chinese): CCMMAA.org

- ISO 9001:2015 Quality Standards: Official Guide

share:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025