- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 07, 2025 01:47

Back to list

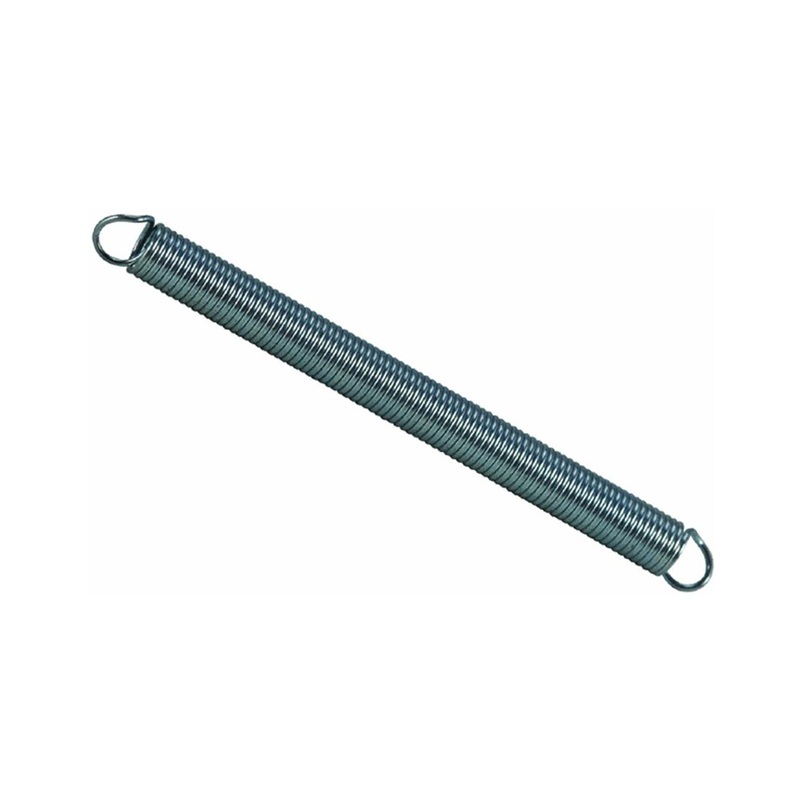

hefty die springs

Hefty die springs are pivotal components in numerous industrial applications, offering robust performance and reliability. Their importance in industries such as automotive, aerospace, and manufacturing cannot be overstated. To fully appreciate their impact, it's vital to delve into their specifications, benefits, and uses, ensuring you can leverage their strengths in your operations.

Moreover, trustworthiness in the use of hefty die springs is enhanced by adhering to industry standards and certifications. Certifications from organizations like ISO and ASTM provide a benchmark of quality and performance, ensuring that the springs you use are manufactured to the highest standards. By choosing springs that meet these rigorous standards, companies can mitigate the risk of equipment failure and reduce maintenance costs over time. Additionally, engaging with suppliers who have a reputation for quality and service can further reinforce this trust. In competitive industrial landscapes, hefty die springs provide an edge not only through their mechanical properties but also via improvements in operational efficiency. Their robustness reduces downtime associated with spring failures, thereby increasing productivity. In cases where machinery is critical to production lines, such reliability can translate into significant cost savings and enhanced throughput, giving companies an advantage in terms of both financial performance and market competitiveness. Furthermore, hefty die springs are continually evolving with advancements in materials science and engineering. Innovations in alloy compositions and manufacturing processes are pushing the boundaries of what these components can achieve—extending their lifespan, improving load capacities, and reducing their footprint. Staying informed about these advancements is crucial for engineers and industry professionals intent on leveraging the latest in spring technology for optimal performance. Ultimately, hefty die springs represent a vital element for industries that demand unwavering reliability under challenging conditions. Their use not only fulfills specific mechanical needs but also contributes to broader operational goals, such as reducing costs and improving efficiency. By ensuring that these springs are selected, implemented, and maintained correctly, companies can confidently rely on them as a cornerstone in their production and operational strategies. In summary, hefty die springs are invaluable to industrial applications needing durable, high-performance solutions. Their expertise-backed selection, adherence to authoritative standards, and trustworthy performance underscore their prominence in modern engineering realms. Companies capitalizing on these springs will find themselves better equipped to navigate the challenges of today's industrial demands, ultimately driving success and innovation across their fields of endeavor.

Moreover, trustworthiness in the use of hefty die springs is enhanced by adhering to industry standards and certifications. Certifications from organizations like ISO and ASTM provide a benchmark of quality and performance, ensuring that the springs you use are manufactured to the highest standards. By choosing springs that meet these rigorous standards, companies can mitigate the risk of equipment failure and reduce maintenance costs over time. Additionally, engaging with suppliers who have a reputation for quality and service can further reinforce this trust. In competitive industrial landscapes, hefty die springs provide an edge not only through their mechanical properties but also via improvements in operational efficiency. Their robustness reduces downtime associated with spring failures, thereby increasing productivity. In cases where machinery is critical to production lines, such reliability can translate into significant cost savings and enhanced throughput, giving companies an advantage in terms of both financial performance and market competitiveness. Furthermore, hefty die springs are continually evolving with advancements in materials science and engineering. Innovations in alloy compositions and manufacturing processes are pushing the boundaries of what these components can achieve—extending their lifespan, improving load capacities, and reducing their footprint. Staying informed about these advancements is crucial for engineers and industry professionals intent on leveraging the latest in spring technology for optimal performance. Ultimately, hefty die springs represent a vital element for industries that demand unwavering reliability under challenging conditions. Their use not only fulfills specific mechanical needs but also contributes to broader operational goals, such as reducing costs and improving efficiency. By ensuring that these springs are selected, implemented, and maintained correctly, companies can confidently rely on them as a cornerstone in their production and operational strategies. In summary, hefty die springs are invaluable to industrial applications needing durable, high-performance solutions. Their expertise-backed selection, adherence to authoritative standards, and trustworthy performance underscore their prominence in modern engineering realms. Companies capitalizing on these springs will find themselves better equipped to navigate the challenges of today's industrial demands, ultimately driving success and innovation across their fields of endeavor.

share:

Next:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025