- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

1月 . 14, 2025 10:39

Back to list

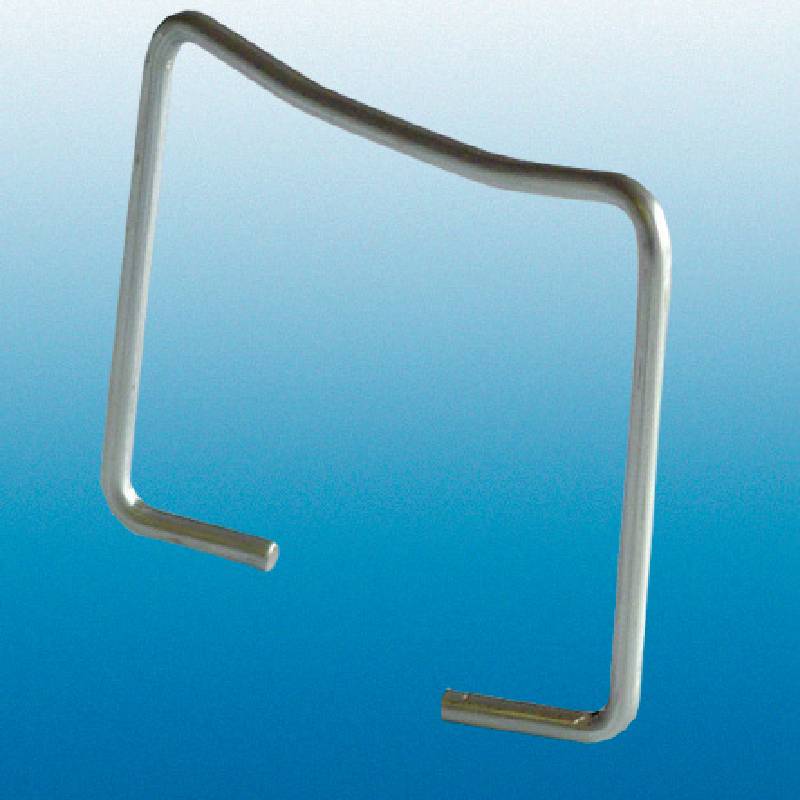

masonry veneer anchor

Masonry veneer anchors, an essential component in modern construction, ensure lasting durability and structural integrity for masonry veneer systems. These sophisticated fittings connect the masonry veneer to the building's structural framework, making them indispensable for both aesthetics and safety in architectural projects.

On-site experience provides valuable insights into common installation challenges and their solutions. Proper spacing of anchors, typically one anchor for every 2.67 square feet, is a critical consideration. Incorrect spacing can lead to structural weaknesses and eventual system failure. Additionally, checking the compatibility of anchors with different insulation materials is vital since improper combinations can lead to thermal bridges, affecting the energy efficiency of a building. The trustworthiness of masonry veneer anchors greatly depends on the quality and reliability of the product manufacturers. It's crucial to source these materials from reputable companies known for rigorous product testing and quality assurance processes. Contractors often establish partnerships with suppliers who provide detailed technical support and installation training, ensuring every anchor meets the project's specific demands. Masonry veneer anchors significantly contribute to the energy efficiency and sustainability of buildings. By facilitating the use of continuous insulation and air barriers, they support a reduction in energy costs and environmental footprint. This aligns with the growing trend of green building practices, making them an increasingly popular choice for LEED-certified projects. In conclusion, masonry veneer anchors are more than just functional components; they are vital to the holistic performance of masonry veneer structures. Their proper selection, installation, and maintenance ensure not only the structural integrity and aesthetic appeal of a building but also enhance its energy efficiency and sustainability. Professionals in construction, architecture, and engineering must prioritize these factors to deliver successful masonry projects that stand the test of time, ensuring safety, beauty, and environmental responsibility.

On-site experience provides valuable insights into common installation challenges and their solutions. Proper spacing of anchors, typically one anchor for every 2.67 square feet, is a critical consideration. Incorrect spacing can lead to structural weaknesses and eventual system failure. Additionally, checking the compatibility of anchors with different insulation materials is vital since improper combinations can lead to thermal bridges, affecting the energy efficiency of a building. The trustworthiness of masonry veneer anchors greatly depends on the quality and reliability of the product manufacturers. It's crucial to source these materials from reputable companies known for rigorous product testing and quality assurance processes. Contractors often establish partnerships with suppliers who provide detailed technical support and installation training, ensuring every anchor meets the project's specific demands. Masonry veneer anchors significantly contribute to the energy efficiency and sustainability of buildings. By facilitating the use of continuous insulation and air barriers, they support a reduction in energy costs and environmental footprint. This aligns with the growing trend of green building practices, making them an increasingly popular choice for LEED-certified projects. In conclusion, masonry veneer anchors are more than just functional components; they are vital to the holistic performance of masonry veneer structures. Their proper selection, installation, and maintenance ensure not only the structural integrity and aesthetic appeal of a building but also enhance its energy efficiency and sustainability. Professionals in construction, architecture, and engineering must prioritize these factors to deliver successful masonry projects that stand the test of time, ensuring safety, beauty, and environmental responsibility.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025