introduzione al prodotto

La molla di torsione è una molla che esercita una coppia quando ruotata. Di solito è realizzato in filo di acciaio per molle e può essere trovato in varie forme e dimensioni, come dritto, a spirale o a spirale. Le caratteristiche delle molle di torsione includono la costante elastica (coefficiente elastico), la coppia massima, l'angolo libero, ecc.

Scenari di applicazione del prodotto

Le molle di torsione sono ampiamente utilizzate in molti settori, come quello automobilistico, dei macchinari, dell'elettronica e dei mobili. Nelle automobili, le molle di torsione si trovano nei sistemi di frizione, freno e cintura di sicurezza. Nei macchinari vengono utilizzati in interruttori, valvole e attuatori. In elettronica vengono utilizzati in connettori, interruttori e sensori. Nei mobili vengono utilizzati nei cassetti, nelle ante e nelle cerniere.

Processo di produzione del prodotto

Il processo di produzione delle molle a torsione prevede la formatura del filo, il trattamento termico, il trattamento superficiale e l'assemblaggio. Innanzitutto, il filo di acciaio per molle viene modellato nella forma desiderata utilizzando macchine per la formatura del filo. Quindi, il filo formato viene trattato termicamente per migliorarne l'elasticità e la durata. Dopo il trattamento termico, il filo può essere trattato in superficie per prevenire la corrosione. Infine, la molla viene assemblata e testata per garantirne la qualità e le prestazioni.

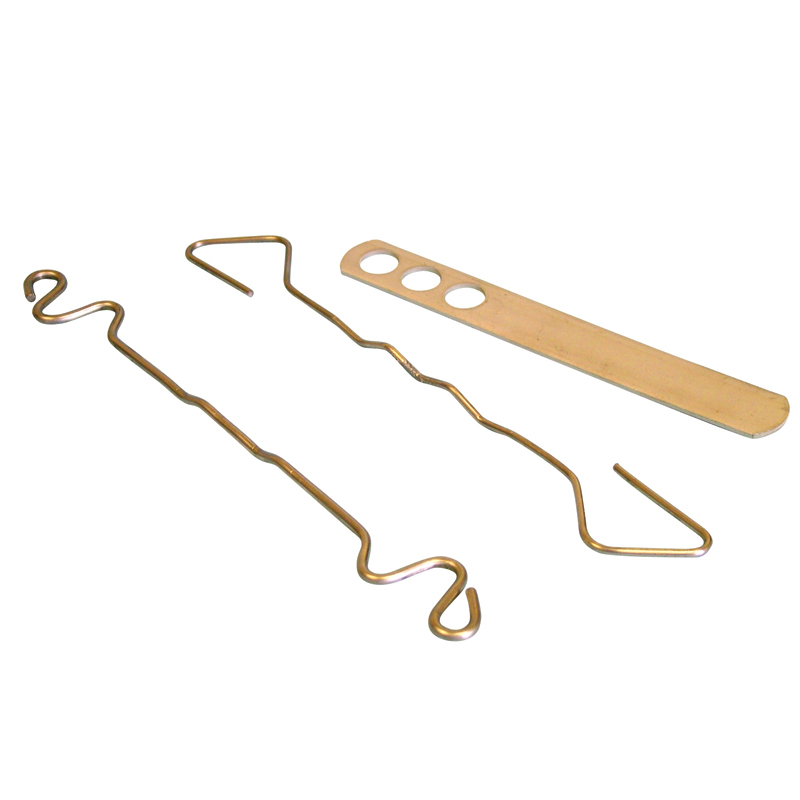

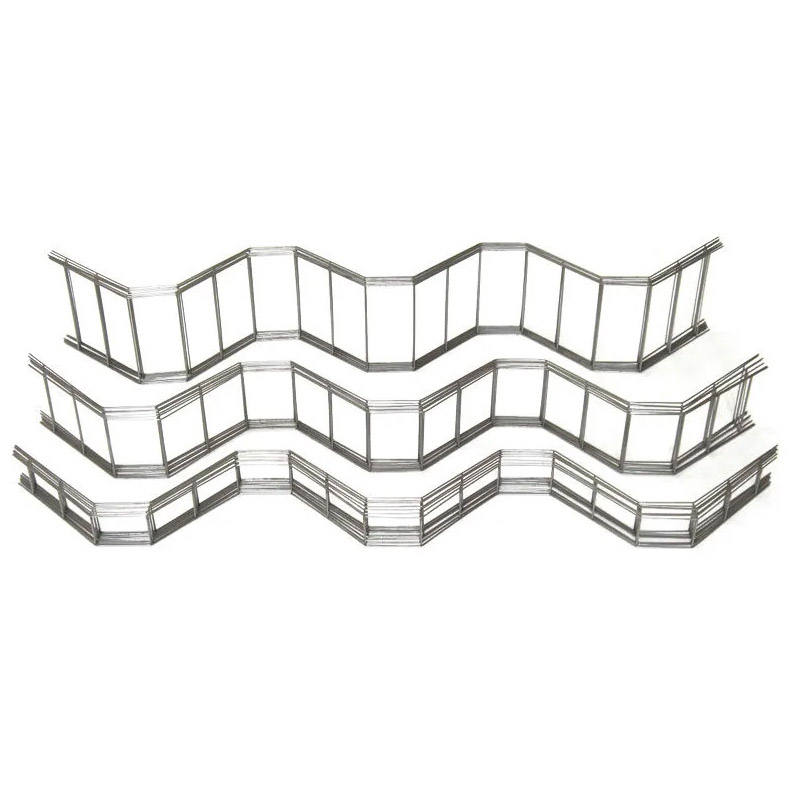

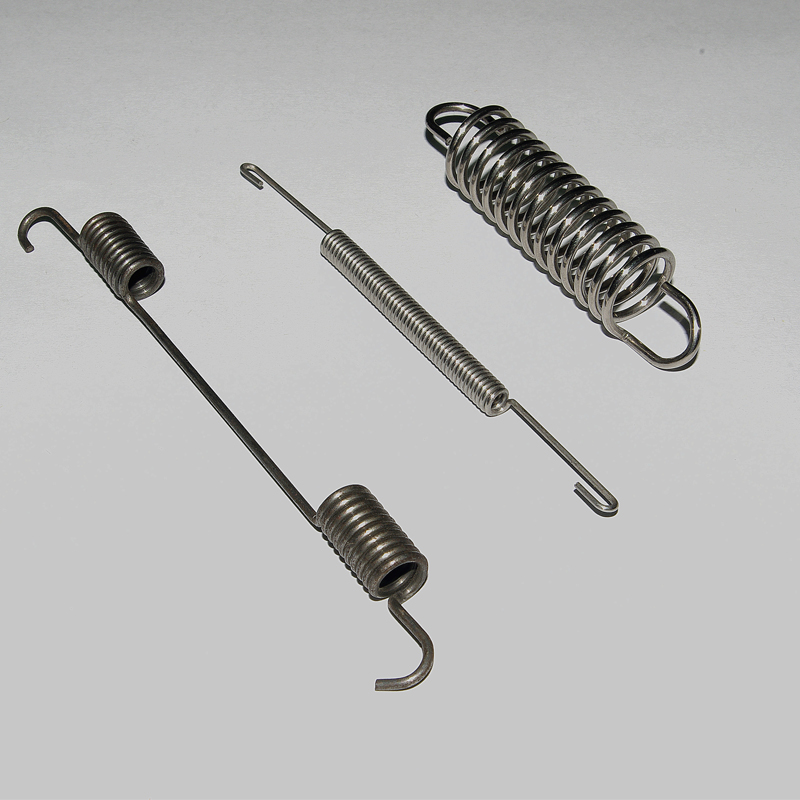

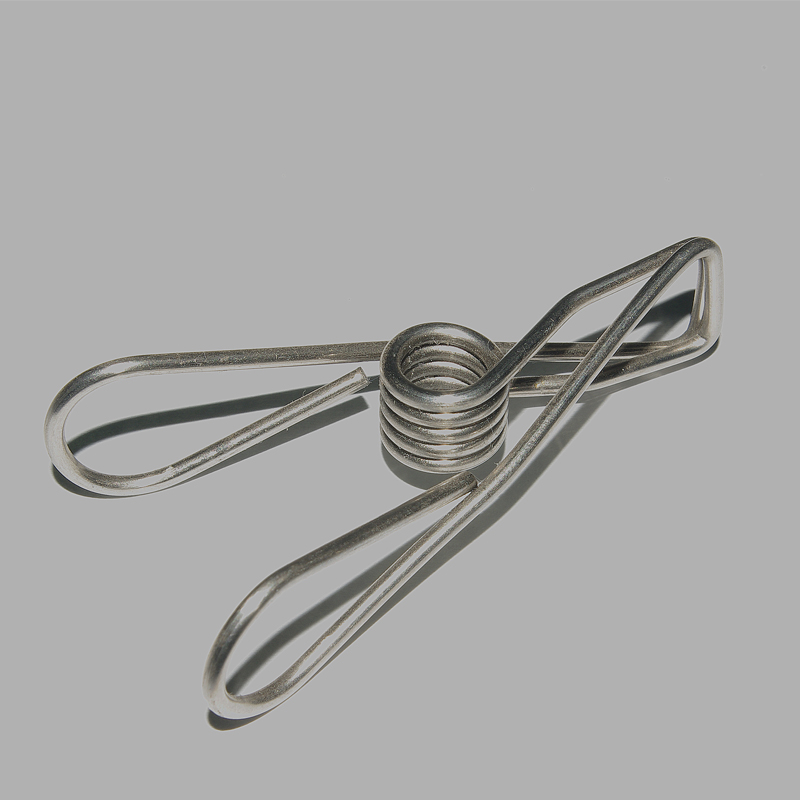

Esposizione del prodotto

|

|

|

|

Nella nostra azienda, possiamo produrre qualsiasi forma e qualsiasi molla industriale in base alle esigenze del cliente e possiamo personalizzarla in base ai disegni del cliente, ecc. I nostri ingegneri e tecnici esperti lavoreranno a stretto contatto con i clienti per garantire che le molle di torsione personalizzate soddisfino le loro esatte specifiche e requisiti di prestazione.

How to Measure a Torsion Spring

Accurate measuring torsion spring dimensions is a crucial step for proper replacement or custom manufacturing. An incorrect measurement may lead to performance failure or mechanical wear. At Shijiazhuang TangChao Metal Products Co., Ltd., we specialize in producing custom torsion springs with precise specifications that match your design and application needs.

There are five essential dimensions to capture when measuring a torsion spring:

1.Wire Diameter – Use a caliper to measure the wire thickness. This affects the spring’s torque capacity and overall strength.

2.Outer Diameter (OD) – This is the full diameter of the coil, including the wire. It’s especially important in tight assemblies.

3.Inner Diameter (ID) – Sometimes required instead of OD. It can be calculated as OD minus twice the wire diameter.

4.Body Length – Measure the length of the coil body without including the legs.

5.Leg Length and Orientation – Note the length of each leg and their position, angle, and direction (clockwise or counterclockwise).

In addition to dimensions, material type also plays a vital role. We manufacture springs using various metals, including steel torsion spring and galvanized finishes for corrosion resistance. Whether you require stock torsion springs or unique geometries like V-shaped or bidirectional torsion spring types, our facility, equipped with advanced machinery from Germany, Korea, and Taiwan, ensures exceptional precision and repeatability.

Shijiazhuang TangChao Metal Products Co., Ltd., founded in 1998, has over two decades of experience delivering high-performance springs to clients in the USA, Europe, Japan, and beyond. Our technical staff can assist you in both measuring and designing the right torsion spring for your application.

Whether you're in automotive, industrial machinery, or consumer electronics, accurate spring measurement is the first step to seamless function. If you're unsure how to proceed, contact our engineers and ask about our torsion springs for sale — we’ll help you get the fit and performance just right.

Extension vs. Torsion Springs: What’s the Difference?

Understanding the difference between extension and torsion springs is essential for selecting the right spring type for your mechanical needs. Though both are used to store and release energy, they operate in entirely different ways.

Function and Motion Direction

Extension springs stretch to provide resistance when pulled apart, storing energy in tension. In contrast, torsion springs operate by twisting; they store energy in a rotational or angular direction. You’ll often find torsion types in clothespins, garage doors, or industrial latches.

Shape and Hook Configuration

Extension springs typically feature looped ends or hooks, while torsion coil spring types have straight or angular legs that rotate around the center axis. Our factory supplies everything from straight torsion spring to more complex rotary springs that suit specific design requirements.

Installation Method

Torsion springs are mounted around a shaft and are twisted to create torque. Extension springs, on the other hand, are attached at two ends and extended when force is applied. This makes torsion ideal for compact spaces where rotation, not linear motion, is required.

Material and Application Differences

At Shijiazhuang TangChao Metal Products Co., Ltd., we manufacture both spring types using premium-grade steel and galvanized finishes. Whether it's a metal torsion spring for a rotary lock or an extension spring for a farm gate, we offer tailored solutions and ready inventory. Our custom torsion springs are widely used in global markets thanks to our advanced production line and experienced team.

While both types have critical uses, the key difference lies in the direction of applied force and energy storage. Torsion models handle angular force; extension models deal with straight-line tension. If you're deciding between the two, consider your application’s movement pattern, available space, and required load response.

If you're in search of durable and precisely engineered components, browse our selection of torsion springs for sale or consult with our engineers to develop a spring system that fits perfectly.