- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Premium Brick Tie Backs & Veneer Anchors

Understanding the Critical Role of brick tie backs in Modern Masonry

In contemporary construction, especially in B2B masonry projects, the integrity and longevity of brick veneer walls are paramount. This is where brick tie backs play a non-negotiable role. These essential components, also known as brick wire ties, masonry tie backs, or even frame ties for brickwork, provide crucial structural connection between the outer brick veneer and the inner structural wall. Their primary function is to transfer lateral loads, such as wind pressure and seismic forces, from the veneer to the main structure, preventing bowing, cracking, and potential collapse. The selection of appropriate tie backs directly impacts the long-term performance and safety of buildings, making it a critical consideration for architects, engineers, and contractors alike. Understanding the nuances of these elements is vital for ensuring compliance with building codes and achieving optimal structural stability.

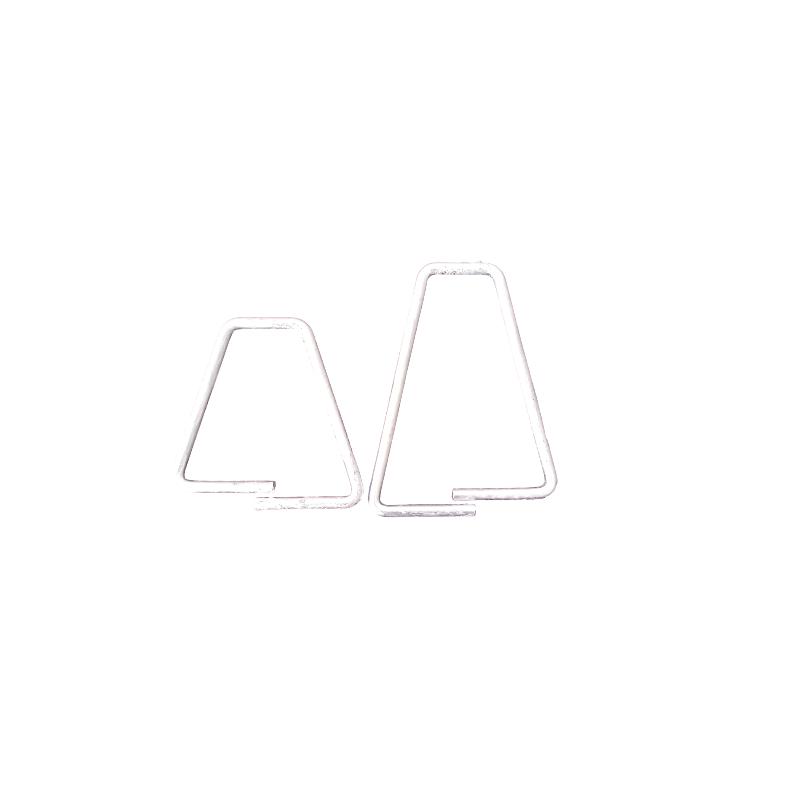

The evolution of building materials and construction techniques has driven significant advancements in tie back design and material science. Modern brick wall straps are engineered for superior corrosion resistance and load-bearing capacity, adapting to diverse environmental conditions and structural demands. Factors such as material composition (e.g., stainless steel, galvanized steel), gauge, and configuration (e.g., triangular, corrugated, adjustable) are meticulously evaluated based on project specifications. Furthermore, the industry is witnessing a trend towards more sustainable and efficient installation methods, with an emphasis on products that offer both high performance and ease of use. As concrete accessories suppliers, our focus is on providing robust solutions like the Triangular Wire Tie, designed to meet the rigorous demands of large-scale construction, ensuring that every brick veneer anchor performs flawlessly under stress.

Manufacturing Excellence: The Process Behind Robust Brick Tie Backs

The production of high-quality brick tie backs, such as the Triangular Wire Tie, involves a sophisticated manufacturing process designed to ensure durability, reliability, and consistent performance. Our process typically begins with the selection of premium raw materials, predominantly high-grade steel wire, including galvanized steel (meeting ASTM A641/A153 standards for corrosion resistance) or stainless steel (SS304 or SS316 for superior environmental resilience). These materials are chosen for their excellent tensile strength and ductility, which are crucial for effective load transfer in masonry applications. The specific type of steel is selected based on the anticipated exposure conditions, ranging from standard atmospheric environments to highly corrosive industrial settings like those found in petrochemical or marine applications.

The manufacturing journey for our wire clips for brick wall involves several precision stages. Initially, large coils of wire undergo a cold-drawing process to achieve the precise diameter and required mechanical properties. Following this, advanced CNC machining or automated wire forming equipment shapes the wire into the specified configurations, such as the triangular design of our product. This automated process ensures dimensional accuracy and consistency, minimizing material waste and maximizing production efficiency. For enhanced corrosion resistance, especially with carbon steel variants, a hot-dip galvanization process is applied, coating the wire with a protective zinc layer. This layer acts as a sacrificial anode, significantly extending the service life of the tie backs, particularly in challenging environments. Each batch undergoes rigorous quality control, including tensile strength tests, bend tests, and coating thickness measurements, adhering to international standards like ISO 9001 and relevant ASTM specifications, ensuring a lifespan often exceeding 50 years under normal conditions.

Technical Specifications of Triangular Wire Ties

The effectiveness of a brick veneer anchor hinges on its precise technical specifications. Our Triangular Wire Tie, designed as a robust solution for diverse masonry applications, boasts characteristics that ensure superior performance and compliance with industry standards. Key parameters include wire gauge, material composition, length, and specific load capacities. These specifications are critical for engineers and contractors to select the appropriate tie for their project’s structural demands, considering factors such as cavity width, seismic zone requirements, and wind load classifications. Our products are engineered to provide maximum lateral support while accommodating differential movement between the veneer and the structural backup.

| Parameter | Description | Typical Value/Standard |

|---|---|---|

| Material | Hot-dip Galvanized Steel (HDG) or Stainless Steel (SS304/SS316) | ASTM A153 (HDG), ASTM A276 (SS) |

| Wire Gauge (Diameter) | Standard wire thickness for structural integrity | Typically 9 gauge (3.76mm) or 3/16" (4.76mm) |

| Overall Length | Length customized to cavity width and embedment | 4", 6", 8", 10", 12" (100mm to 300mm) |

| Tensile Strength | Maximum stress material can withstand before breaking | Varies by gauge/material, e.g., >500 MPa for SS |

| Yield Strength | Stress at which permanent deformation occurs | Varies by gauge/material, e.g., >200 MPa for SS |

| Corrosion Resistance | Ability to resist degradation from environment | Excellent (HDG) to Superior (SS304/316) |

| Applicable Codes | Relevant building and material codes | ASTM A82, ASTM E2921, ASCE/SEI 7, IBC, IRC |

These specifications ensure that our products, including components like the rebar positioner or dw 10hs veneer anchors, integrate seamlessly into various structural designs. The emphasis on high tensile and yield strength guarantees the structural integrity required to withstand significant loads, while superior corrosion resistance ensures longevity, even in harsh industrial or coastal environments. Our commitment to adhering to rigorous ASTM and ISO standards provides assurance that our brick tie backs meet or exceed the performance expectations for critical B2B construction projects.

Diverse Applications and Key Industry Insights

The versatility of brick tie backs extends across a broad spectrum of industries and construction types, reinforcing their status as indispensable components for structural stability. From towering commercial high-rises to sprawling industrial complexes and critical infrastructure, these elements are fundamental in securing masonry veneers. In the petrochemical industry, where structures are exposed to aggressive chemicals and extreme temperatures, the corrosion-resistant properties of stainless steel tie backs are paramount. Similarly, in the metallurgy sector, the ability to withstand high thermal loads and corrosive atmospheres makes robust masonry tie backs a necessity. Public and private infrastructure projects, including bridges, tunnels, and water treatment plants (given their exposure to water supply and drainage systems), also heavily rely on these durable connectors to maintain the long-term integrity of their facades.

Beyond these specific industries, brick tie backs are crucial in general commercial and residential construction, providing enhanced safety and longevity for building envelopes. For instance, in seismic-prone regions, specifically engineered brick wall straps are critical for ensuring the ductility and energy dissipation necessary to prevent catastrophic structural failure during an earthquake. Our Triangular Wire Tie offers a design that not only facilitates secure embedment but also allows for minimal yet critical movement, accommodating thermal expansion and contraction without compromising the connection. This adaptability translates into significant advantages, including improved energy efficiency by maintaining the integrity of the insulation layer within the cavity, and substantial anti-corrosion benefits due to advanced material treatments. A case study from a recent commercial office tower project in a coastal region demonstrated that our SS316 tie backs reduced maintenance costs by 30% over five years compared to standard galvanized alternatives, primarily due to their superior resistance to salt-laden air.

Custom Solutions and Client-Centric Approaches

Recognizing that every B2B project presents unique challenges, we specialize in providing tailored solutions for brick tie backs. Our expertise extends beyond standard product offerings to include custom fabrication and consultation, ensuring that even the most complex architectural or structural demands are met with precision. Whether it's a unique cavity width, specific load-bearing requirements, or an unusually aggressive environmental condition, our engineering team collaborates closely with clients to design and deliver bespoke wire clips for brick wall that integrate seamlessly with their project specifications. This consultative approach not only guarantees optimal performance but also often results in cost efficiencies by preventing over-engineering or material waste. We leverage our extensive experience as concrete accessories suppliers to anticipate project needs and provide proactive support, making us a trusted partner in large-scale construction.

Our commitment to customer satisfaction is exemplified by our rapid prototyping capabilities for customized masonry tie backs and our responsive technical support. For a recent heritage building restoration project, the client required bespoke frame ties for brickwork that could accommodate an irregular wall thickness while maintaining historical aesthetic integrity. Our team rapidly designed and manufactured a custom offset tie, which not only met the structural requirements but also facilitated a faster, less disruptive installation process, saving the client approximately 15% on labor costs. This level of dedication to specialized solutions, coupled with our consistent product quality, has fostered long-term partnerships with leading contractors and developers. We pride ourselves on delivering not just products, but comprehensive solutions that contribute to the success and structural integrity of our clients' most ambitious projects, including specialized items like rebar positioners when concrete elements are involved.

Why Choose Our Brick Tie Backs: Trust and Assurance

Choosing the right supplier for brick tie backs is as critical as selecting the product itself. With over two decades of experience in the metal fabrication industry, our company has established itself as a beacon of reliability and expertise. We are ISO 9001 certified, a testament to our unwavering commitment to quality management systems and continuous improvement. Our products, including our Triangular Wire Tie and dw 10hs veneer anchors, consistently meet or exceed ASTM and ANSI standards, validated through stringent in-house and third-party testing. We've partnered with numerous industry leaders on landmark projects, delivering millions of units with zero reported field failures related to product quality. Our authoritative standing is further reinforced by our long-standing relationships with top-tier general contractors and structural engineering firms who regularly specify our products due to their proven performance.

Our dedication to client success extends beyond product quality. We offer transparent delivery cycles, typically ranging from 2-4 weeks for standard orders, with expedited options available for urgent projects, communicated clearly at the quotation stage. Every product is backed by a comprehensive 10-year structural warranty, underscoring our confidence in its durability and performance. Furthermore, our dedicated customer support team provides unparalleled service, from initial technical consultation and material selection guidance to post-delivery assistance. Clients benefit from direct access to our engineering experts, ensuring that any queries or challenges are addressed swiftly and effectively. This holistic approach to service, combined with our robust product line, solidifies our position as a trustworthy and authoritative partner for all your masonry tie back needs.

Frequently Asked Questions (FAQs) About Brick Tie Backs

Q: What is the primary purpose of a brick tie back?

A: The primary purpose of a brick tie back is to connect the exterior brick veneer to the interior structural wall. This connection transfers lateral loads (like wind pressure or seismic forces) from the veneer to the main structure, preventing bowing, cracking, and ensuring the stability and safety of the facade. They are crucial for maintaining the integrity of brick wall straps systems.

Q: What materials are commonly used for brick wire ties?

A: Brick wire ties are typically manufactured from hot-dip galvanized steel (HDG) or various grades of stainless steel (SS304 or SS316). The choice of material depends on the desired corrosion resistance, structural strength requirements, and environmental conditions of the project. Stainless steel offers superior resistance to corrosive environments, making it ideal for coastal or industrial applications.

Q: How do brick veneer anchors accommodate building movement?

A: Many brick veneer anchors, including our Triangular Wire Tie, are designed to allow for slight differential movement between the brick veneer and the structural backup. This is crucial for accommodating thermal expansion and contraction, as well as minor structural deflections, without placing undue stress on the masonry. While they restrain lateral movement, they typically permit vertical or in-plane sliding, preventing stress concentrations that could lead to cracking.

Q: What industry standards should I look for when specifying masonry tie backs?

A: When specifying masonry tie backs, it is essential to ensure they comply with relevant industry standards such as ASTM International standards (e.g., ASTM A82 for steel wire, ASTM A153 for hot-dip galvanization, ASTM E2921 for testing methods), and applicable building codes like the International Building Code (IBC) or local municipal codes. Compliance with ISO 9001 for the manufacturer's quality management system also provides an assurance of consistent product quality.

Q: Can brick tie backs be customized for specific project needs?

A: Yes, absolutely. Professional concrete accessories suppliers often offer custom fabrication services for brick tie backs. This includes varying lengths, wire gauges, specialized configurations (like those for irregular cavity widths or unique structural attachments, such as integration with a rebar positioner), and specific material finishes to meet the precise demands of unique architectural designs or challenging environmental conditions. Custom solutions ensure optimal structural performance and installation efficiency.

References

- American Society for Testing and Materials (ASTM) Standards for Masonry.

- International Building Code (IBC) and International Residential Code (IRC) for Masonry Design.

- Masonry Standards Joint Committee (MSJC) Building Code Requirements for Masonry Structures (ACI 530/ASCE 5/TMS 402).

- National Institute of Standards and Technology (NIST) Publications on Structural Engineering.

- Journals of the American Concrete Institute (ACI) and American Society of Civil Engineers (ASCE).

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025