- Mobiltelefon

- +8613931874955

- sales@cntcmetal.com

Environmental Impact of Using Snake Spacers in Plumbing

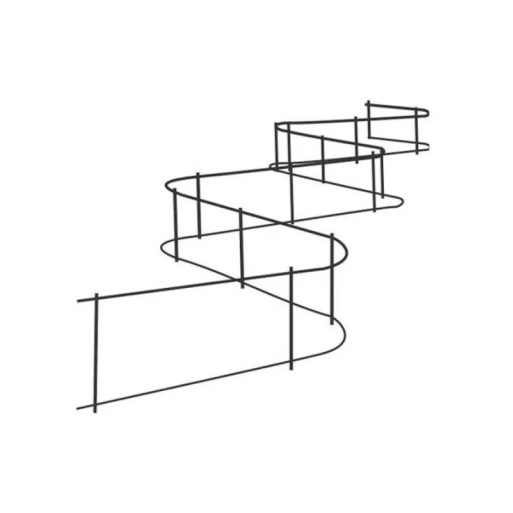

In plumbing systems, snake spacers, wire spacer, és concrete wire spacer play crucial roles in maintaining structure and functionality, but their environmental footprint is often overlooked. These components, designed to support pipes, reinforce concrete, or create gaps for water flow, can impact ecosystems through their materials, manufacturing, and disposal. Shijiazhuang TangChao Metal Products Co., Ltd., a professional manufacturer of construction accessories—including galvanized wire, wire mesh, and various wire products—understands the balance between functionality and sustainability. Their expertise in wire forming and metal products extends to creating efficient spacers, such as snake spacers, which are supplied in 2.0 - metre lengths with sizes ranging from 20mm to 400mm, offering a quick and economical solution for reinforcing concrete slabs and panels.

Material Composition and Environmental Footprint of Snake Spacers

- Metal-Based Spacers: Most snake spacers and wire spacer products are made from steel or galvanized wire. The production of these metals involves mining raw materials, which disrupts ecosystems and consumes large amounts of energy. Galvanization, a process to prevent corrosion, uses zinc, and its extraction can lead to soil and water pollution if not managed properly.

- Plastic Alternatives: Some snake spacersare made from plastics, which reduce corrosion risks but introduce other environmental concerns. Plastic production relies on fossil fuels, contributing to greenhouse gas emissions. Additionally, plastic spacers can leach microplastics into soil and water over time, especially in plumbing systems where they come into contact with water.

- Concrete Wire Spacer Materials: Concrete wire spacercombines wire with concrete, leveraging the durability of both materials. However, concrete production is energy - intensive, releasing carbon dioxide during cement manufacturing. The wire component, often steel, adds to the overall carbon footprint due to its production process.

Environmental Impact During Use of Wire Spacer in Plumbing

- Corrosion and Leaching: Metal wire spacerand snake spacers can corrode over time, especially in plumbing systems with acidic or mineral - rich water. Corrosion leads to the release of metal particles into water, which may contaminate water sources. While galvanized spacers resist corrosion longer, the zinc coating can eventually wear away, leading to similar issues.

- Energy Efficiency: Properly installed snake spacersensure pipes are aligned correctly, reducing friction and improving water flow. This can enhance the energy efficiency of plumbing systems, as pumps and water heaters don’t have to work as hard to maintain pressure. Conversely, poorly designed spacers that cause blockages or leaks can increase energy consumption and water waste.

- Wildlife Interaction: In outdoor plumbing systems, exposed concrete wire spaceror broken wire spacer can pose risks to wildlife. Small animals may get entangled in wire components, and sharp edges can cause injuries. Additionally, if spacers end up in waterways, they can disrupt aquatic habitats.

Disposal and End - of - Life Impact of Snake Spacers

- Landfill Contributions: Most snake spacers and concrete wire spacerend up in landfills when plumbing systems are replaced. Metal spacers are slow to degrade, and plastic ones can persist for centuries, taking up valuable landfill space. Concrete spacers, while biodegradable over time, break down into debris that may contain heavy metals from the wire component.

- Recycling Potential: Metal wire spacerand snake spacers are recyclable, which can reduce their environmental impact. Recycling steel and zinc reduces the need for mining and lowers energy consumption compared to producing new materials. However, recycling rates for these small components are often low due to collection challenges.

- Incineration Risks: Plastic snake spacersthat are incinerated release toxic fumes, contributing to air pollution. This process also wastes the material’s potential for recycling and adds to greenhouse gas emissions, making it a less sustainable disposal option.

Comparing Environmental Impact of Different Spacer Types

|

Spacer Type |

Production Emissions |

Degradation Time |

Recyclability |

Primary Environmental Concern |

|

Snake Spacers (Metal) |

High (mining, galvanizing) |

Slow (decades) |

High |

Corrosion - related water contamination |

|

Wire Spacer (Plastic) |

Medium (fossil fuel use) |

Very Slow (centuries) |

Low |

Microplastic leaching, landfill accumulation |

|

Concrete Wire Spacer |

High (concrete + metal) |

Medium (years) |

Low |

Carbon footprint from concrete production |

Snake Spacers FAQS

Do Snake Spacers Contribute to Water Pollution?

Yes, over time, metal snake spacers can corrode and release metal particles into water, potentially contaminating it. Plastic spacers may leach microplastics, especially in prolonged contact with water. Proper maintenance and material selection can minimize these risks.

Are Wire Spacer More Environmentally Friendly Than Concrete Wire Spacer?

It depends on the material. Metal wire spacer has a higher recycling potential than concrete wire spacer, but concrete spacers don’t leach microplastics. Wire spacer made from recycled metal is often a more sustainable choice than concrete ones due to lower long - term environmental impact.

How Long Do Snake Spacers Last in Plumbing Systems?

Snake spacers typically last many years, depending on the material and environmental conditions. Galvanized metal spacers resist corrosion longer than non - galvanized ones, while plastic spacers may degrade faster in high - temperature or chemical - rich environments.

Can Snake Spacers Be Recycled After Use?

Fém snake spacers are recyclable, as steel and zinc can be melted down and reused. Plastic spacers are harder to recycle, especially if they’re contaminated with water or chemicals. Proper cleaning and separation improve recycling chances.

How Does Shijiazhuang TangChao Metal Products Co., Ltd. Address Environmental Concerns in Spacer Production?

Shijiazhuang TangChao Metal Products Co., Ltd. focuses on sustainable materials and efficient production processes for their wire products, including wire spacer. Their use of galvanized wire, which resists corrosion and extends product life, and commitment to quality reduce the need for frequent replacements, lowering environmental impact.

Ossza meg:

-

Creative Ways to Decorate Your Tomato CagehírekAug.22,2025

-

Common Mistakes When Installing Brick Wall TieshírekAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationshírekAug.22,2025

-

Galvanized Tie Wire for Binding PipeshírekAug.22,2025

-

Sacrificial Formwork Systems for Complex StructureshírekAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityhírekAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionhírekAug.08,2025