- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Concrete Wall Ties for Sale | Premium Masonry & Formwork Ties

The Imperative Role of Concrete Wall Ties in Modern Construction: A Comprehensive Insight

In the intricate world of modern construction, the integrity and longevity of structures hinge on a multitude of components, many of which operate discreetly, yet perform critical functions. Among these indispensable elements are concrete wall ties for sale, vital connectors that bridge the gap between structural elements, primarily facilitating the secure attachment of masonry veneers to concrete or steel frames. These engineered components, often classified under the broader category of masonry accessories, are fundamental in preventing bowing, cracking, and eventual collapse of exterior walls, particularly in multi-story buildings subjected to dynamic environmental loads like wind pressure, seismic activity, and thermal expansion and contraction. The selection of appropriate wall ties is not merely a matter of convenience but a critical engineering decision that directly impacts the structural resilience, energy efficiency, and overall safety profile of a building. The global construction industry, constantly evolving with advancements in materials science and structural engineering, places an increasing emphasis on precision-engineered solutions that offer superior performance, ease of installation, and long-term durability. This rigorous demand drives innovation in the design and manufacturing of concrete wall ties, prompting manufacturers to adhere to stringent international standards and leverage advanced metallurgical processes. Beyond their primary structural role, these ties also play a subtle yet significant part in managing moisture ingress and acoustic performance, making their specification a multifaceted consideration for architects, structural engineers, and contractors. Understanding the nuanced interplay of material science, manufacturing precision, and application-specific demands is paramount for any stakeholder seeking optimal structural outcomes. The emphasis on high-performance solutions is further amplified by the pressing need for sustainable construction practices, where the longevity and recyclability of building components contribute directly to reduced environmental footprints. As projects become more ambitious in scale and complexity, the reliance on robust, compliant, and innovative concrete accessories becomes increasingly pronounced, solidifying the position of specialized components like concrete wall ties as cornerstones of resilient and enduring architectural masterpieces. The comprehensive understanding of these ties, from their foundational material properties to their advanced application techniques, is indispensable for delivering projects that not only meet but exceed contemporary building codes and performance expectations. This article delves into the technical intricacies, market dynamics, and operational best practices surrounding these essential construction elements, providing a holistic perspective for B2B professionals.

Industry Trends and Market Dynamics Shaping Concrete Wall Ties Supply

The market for concrete wall ties for sale is dynamic, influenced by several overarching industry trends and regulatory shifts. A significant trend is the escalating demand for high-performance and corrosion-resistant materials, driven by increasing awareness of building longevity and maintenance costs. Galvanized steel, particularly hot-dip galvanized steel, remains a staple due to its cost-effectiveness and proven corrosion resistance, but there's a growing inclination towards stainless steel (e.g., AISI 304, 316) in coastal regions or highly corrosive industrial environments where extended service life and minimal maintenance are paramount. This shift is not merely about material selection but encompasses a broader understanding of total lifecycle costs, where the initial higher investment in stainless steel is offset by decades of trouble-free performance. Another critical trend is the emphasis on thermal efficiency. Modern building codes, such as those governed by ASHRAE and European Union directives, are pushing for stricter thermal performance targets to reduce energy consumption and carbon footprints. This has led to the development of specialized thermal concrete wall ties designed to minimize thermal bridging, where conventional metal ties can act as pathways for heat transfer, compromising the insulation envelope. Innovations in this area include composite ties made from fiberglass or basalt, which offer significantly lower thermal conductivity while maintaining structural integrity. The burgeoning adoption of prefabricated and modular construction techniques also impacts the demand for wall ties. These methods necessitate precision-engineered components that can be rapidly and securely installed on-site, requiring tight tolerances and standardized designs for various concrete formwork accessories. The rise of digitalization in construction, encompassing Building Information Modeling (BIM) and digital fabrication, further streamlines the specification and procurement processes for these components, enabling more accurate quantity take-offs and reduced waste. Furthermore, global supply chain complexities, influenced by geopolitical factors and raw material price fluctuations, are compelling manufacturers and buyers to seek robust, reliable supply partners capable of ensuring consistent quality and timely delivery. The market is also experiencing a surge in demand for customizable solutions, driven by unique architectural designs and varying structural requirements across diverse projects, from high-rise residential buildings to specialized industrial facilities. Manufacturers offering bespoke designs, tailored lengths, gauges, and end-configurations are gaining a competitive edge. The stringent enforcement of international standards such as ASTM, British Standards (BS), and European Norms (EN) is also paramount, ensuring that products meet specified mechanical properties, corrosion resistance, and fire ratings, thereby mitigating risks and ensuring project compliance. This holistic evolution in the construction landscape necessitates that suppliers of concrete block wall ties not only provide high-quality products but also offer comprehensive technical support, material certifications, and a deep understanding of evolving regulatory frameworks to remain competitive and trusted partners in the construction ecosystem. The increasing focus on resilience against natural disasters, particularly seismic events, has also driven innovations in flexible or seismic ties that can accommodate differential movement without compromising structural integrity, reflecting a proactive approach to risk mitigation in building design.

Technical Specifications and Performance Parameters of Concrete Wall Ties

The performance of concrete wall ties for sale is defined by a rigorous set of technical specifications and material parameters, ensuring their suitability for diverse structural demands. Key among these are the material composition, wire gauge (diameter), length, and specific configurations designed to transfer loads efficiently. Common materials include hot-dip galvanized carbon steel, compliant with ASTM A153 or A653 standards for corrosion resistance, offering a zinc coating thickness of typically 1.0 to 1.8 oz/ft² (approximately 305 to 550 g/m²) for long-term protection in moderate environments. For more aggressive conditions, stainless steel grades like AISI 304 or 316 are preferred, known for their superior resistance to rust, pitting, and crevice corrosion, crucial for applications in coastal areas or industrial settings exposed to chemicals. The wire gauge, often expressed in imperial (e.g., 9 gauge, 3/16 inch) or metric (e.g., 4.76mm) units, directly influences the tie's shear and tensile strength. Thicker gauges provide higher load-bearing capacities, essential for supporting heavier masonry veneers or resisting greater lateral forces. The length of the tie is critical for accommodating varying cavity widths between the structural frame and the masonry veneer, typically ranging from 2 inches (50mm) to 12 inches (300mm) or more, ensuring adequate embedment into both the mortar joint and the concrete substrate. Load transfer mechanisms are paramount; ties are designed to resist both inward and outward pressure, as well as vertical shear forces. The American Concrete Institute (ACI) and Masonry Society (TMS) through ACI 530/530.1 (Building Code Requirements for Masonry Structures and Specifications for Masonry Structures) provide comprehensive guidelines for the design and installation of masonry accessories, including specific requirements for wall ties based on building height, wind zones, and seismic considerations. Performance metrics include ultimate tensile strength, which dictates the maximum pull-out force the tie can withstand before failure, and shear strength, representing its resistance to forces acting parallel to the tie's axis. Compliance with ASTM A82 (Standard Specification for Steel Wire, Plain, for Concrete Reinforcement) for cold-drawn wire, and ASTM A951 (Standard Specification for Steel Wire for Masonry Joint Reinforcement) is often a baseline for quality assurance, specifying minimum yield strength and tensile strength requirements. Beyond material and mechanical properties, design features such as drip details, often found on adjustable brick ties, are essential for preventing moisture from bridging the cavity and compromising insulation or leading to structural dampness. Similarly, pintle ties or seismic ties incorporate specific design elements to allow for differential movement between the veneer and the structure, crucial in areas prone to seismic activity or significant thermal expansion/contraction cycles. These specialized designs help to mitigate stress concentrations and prevent cracking of the masonry facade. The intricate balance of material science, mechanical engineering, and adherence to codes ensures that each brick veneer wall ties provides reliable and enduring performance, making them a cornerstone of durable and safe building envelopes. Understanding these parameters is crucial for engineers to specify the correct tie type for the structural loads and environmental conditions of a given project, ensuring optimal performance and compliance.

| Parameter | Typical Range/Value (Galvanized Steel) | Typical Range/Value (Stainless Steel 304/316) | Relevant Standards |

|---|---|---|---|

| Material Grade | ASTM A653 (G90/G60 Hot-Dip Galvanized) | ASTM A240 / A276 (Type 304, 316) | ASTM, AISI |

| Wire Gauge / Diameter | 9 Gauge (0.148 in / 3.76 mm) to 3/16 in (0.1875 in / 4.76 mm) | 9 Gauge (0.148 in / 3.76 mm) to 3/16 in (0.1875 in / 4.76 mm) | ASTM A82, A951 |

| Yield Strength | Min. 60,000 psi (415 MPa) | Min. 30,000 psi (205 MPa) - 304, 31,000 psi (215 MPa) - 316 | ASTM A82, A951 |

| Tensile Strength | Min. 70,000 psi (485 MPa) | Min. 75,000 psi (515 MPa) - 304, 80,000 psi (550 MPa) - 316 | ASTM A82, A951 |

| Zinc Coating Thickness (Galv. only) | Min. 1.5 oz/ft² (458 g/m²) | N/A | ASTM A153 |

| Tie Length (typical) | 4 in (100mm) to 12 in (300mm), custom lengths available | 4 in (100mm) to 12 in (300mm), custom lengths available | Project Specific |

| Corrosion Resistance | Good (Standard atmospheric) | Excellent (Aggressive atmospheric, coastal, industrial) | ASTM B117 (Salt Spray) |

| Application Temperature Range | -40°C to +200°C | -196°C to +800°C | Material Specific |

Detailed Manufacturing Process for Concrete Wall Ties: Precision and Quality

The production of high-quality concrete wall ties for sale is a multi-stage manufacturing process, emphasizing precision engineering, material integrity, and stringent quality control. It typically begins with the selection of raw materials, primarily high-strength steel wire coils, either plain carbon steel for subsequent galvanization or pre-galvanized, or specific grades of stainless steel. Reputable manufacturers source these materials from certified mills, ensuring compliance with international standards such as ASTM A82 for plain wire or ASTM A240 for stainless steel, guaranteeing consistent mechanical properties like tensile and yield strength. The initial stage involves wire drawing, where hot-rolled wire rod is pulled through a series of dies to reduce its diameter and improve its mechanical properties through cold work hardening. This process enhances the wire's strength, ductility, and surface finish, crucial for the formation of durable wall ties. Following wire drawing, the wires undergo straightening and cutting to precise lengths using automated machinery, minimizing material waste and ensuring dimensional accuracy. For many types of wall ties, particularly those incorporating unique shapes or deformations for better mortar embedment or connection to masonry, a cold forming or stamping process is employed. This could involve bending, crimping, or pressing the wire into specific configurations, such as pintle ends for adjustable ties, or corrugated sections for improved bond. Advanced CNC (Computer Numerical Control) machining might be utilized for complex geometries, ensuring high repeatability and precision. The next critical step for carbon steel ties is surface treatment, most commonly hot-dip galvanization. This involves immersing the fabricated steel ties into a bath of molten zinc at temperatures around 450°C (850°F). The zinc metallurgically bonds with the steel, forming multiple layers of zinc-iron alloy and an outer layer of pure zinc. This coating provides sacrificial protection against corrosion, extending the product's lifespan significantly, especially in outdoor or moderately corrosive environments. The thickness of the zinc coating is meticulously controlled to meet specifications like ASTM A153, which dictates the minimum coating weight for various applications, directly correlating to the anticipated service life. For stainless steel ties, while not requiring galvanization, surface passivation might be performed to enhance their natural corrosion resistance by removing free iron and forming a protective oxide layer.

Throughout the manufacturing cycle, rigorous quality control and inspection standards are applied. This includes visual inspections for defects, dimensional checks using calipers and gauges to ensure compliance with specified lengths, diameters, and bends, and mechanical testing. Mechanical tests typically involve tensile strength tests to verify the wire's breaking point and yield strength, pull-out tests to assess the tie's embedment strength in mortar or concrete, and shear tests to determine its resistance to lateral forces. For galvanized products, coating thickness measurements using magnetic gauges or gravimetric methods (weighing before and after stripping the zinc) are performed to confirm adherence to corrosion protection standards. Furthermore, some manufacturers implement accelerated corrosion testing, such as salt spray tests (ASTM B117), to simulate long-term performance in corrosive environments, providing empirical data on expected service life. The entire process adheres to comprehensive quality management systems like ISO 9001, ensuring traceability of materials, consistent production protocols, and continuous improvement. The typical service life of a hot-dip galvanized concrete wall tie can range from 50 to 100 years or more in typical atmospheric conditions, while stainless steel variants can exceed this, offering performance over the entire design life of a structure, often 100+ years, even in highly aggressive environments. These robust manufacturing processes ensure that brick wire ties and other types of ties meet the critical performance requirements for structural stability, corrosion resistance, and longevity across various building types. Industries applicable include, but are not limited to, commercial and residential construction, industrial facilities (e.g., petrochemical plants, metallurgical sites where corrosive atmospheres are prevalent), infrastructure projects (bridges, tunnels), and wastewater treatment plants, where the need for robust, corrosion-resistant concrete accessories products is paramount. In these demanding environments, the superior anti-corrosion properties of properly manufactured and specified wall ties translate directly into reduced maintenance costs and enhanced structural safety. The energy-saving aspect is often indirectly related but significant, as durable wall ties contribute to the long-term integrity of the building envelope, preserving the effectiveness of insulation and reducing thermal bridging, thereby contributing to lower heating and cooling loads over the building's lifespan. This meticulous approach to manufacturing underscores the commitment of leading suppliers to deliver products that are not only compliant with the most stringent industry standards but also contribute significantly to the long-term durability and efficiency of built environments.

Application Scenarios and Technical Advantages of Robust Wall Ties

The versatility of concrete wall ties for sale extends across a myriad of construction applications, each benefiting from their distinct technical advantages. In multi-story commercial and residential buildings, these ties are indispensable for securely anchoring non-load-bearing masonry veneer walls to structural concrete frames or shear walls. This application is critical for providing lateral stability to the veneer against wind suction and positive pressure, as well as seismic forces. For instance, in high-rise constructions where wind loads can exert immense pressure, properly spaced and sized ties ensure the masonry facade remains integral, preventing bowing or delamination. Their primary advantage here lies in their ability to allow differential movement between the frame and the veneer due to thermal expansion/contraction or minor structural deflections, without compromising the structural connection, especially when using adjustable brick tie designs. In industrial facilities, such as petrochemical plants or metallurgical processing sites, where robust and corrosion-resistant construction is paramount, stainless steel wall ties offer superior performance. The corrosive atmosphere in these environments, often laden with chemical vapors or high humidity, would rapidly degrade standard galvanized ties. Stainless steel’s inherent resistance to chemical attack ensures the long-term integrity of the masonry envelope, minimizing maintenance downtime and enhancing safety. Moreover, in specialized applications like water treatment facilities or certain segments of the food processing industry, hygienic standards and resistance to specific chemicals necessitate the use of premium stainless steel ties, contributing to a clean and durable operational environment.

Beyond structural stability, modern wall ties contribute significantly to thermal and acoustic performance. Innovations such as thermal ties, incorporating non-metallic components like basalt or fiberglass, drastically reduce thermal bridging through the wall cavity. This translates directly into enhanced energy efficiency for the building, reducing heating and cooling loads and supporting green building certifications such like LEED. For instance, a typical steel tie can transfer a significant amount of heat, creating "cold spots" on interior walls and increasing energy consumption. Thermal break ties minimize this heat transfer, preserving the R-value of the insulation and contributing to a more comfortable interior climate. Acoustically, a well-isolated masonry veneer can help in dampening external noise. While wall ties themselves are not primary acoustic barriers, their proper installation and design can prevent sound flanking paths and ensure the integrity of the overall sound insulation system of the wall assembly. In seismic zones, specialized seismic concrete wall ties are engineered to accommodate larger differential movements between the building frame and the veneer. These ties are designed with specific flexibility to absorb energy during an earthquake, preventing brittle failure of the masonry and enhancing the overall resilience of the structure. This is a critical advantage in regions prone to seismic activity, where traditional rigid ties could lead to extensive damage. The ease of installation, particularly for self-tapping or adjustable designs, offers significant labor cost savings and faster construction schedules, another compelling technical advantage for contractors. Suppliers providing comprehensive installation guides and technical support further enhance this benefit. Ultimately, the careful selection and precise installation of high-quality brickwork accessories like concrete wall ties directly translate into long-term savings from reduced maintenance, improved energy performance, enhanced safety, and greater structural integrity, making them an invaluable investment in any substantial construction project. The ongoing research and development in composite materials and advanced manufacturing techniques continue to push the boundaries of performance for these essential components, offering solutions that are increasingly tailored to the evolving demands of the global construction market, particularly in sectors requiring high-performance envelopes.

Manufacturer Comparison and Tailored Solutions for Concrete Wall Ties

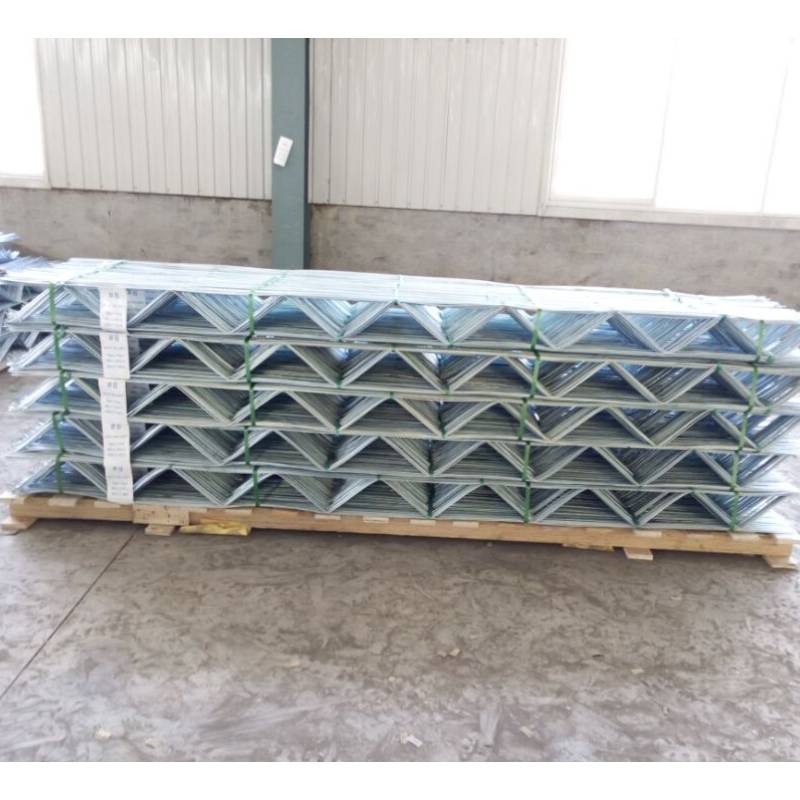

Selecting the right manufacturer for concrete wall ties for sale is a critical decision that impacts project timelines, budget, and long-term structural integrity. While numerous suppliers exist, a discerning approach involves evaluating a manufacturer's adherence to international standards, their material sourcing policies, their manufacturing capabilities, and their commitment to customer support and customized solutions. Leading manufacturers distinguish themselves by consistently producing ties that meet or exceed rigorous standards like ASTM, British Standards (BS), and Eurocodes, backed by comprehensive test reports and certifications, such as ISO 9001 for quality management systems. Companies like CNTC Metal, for example, leverage extensive experience in metal fabrication to produce a range of Truss Mesh Masonry Joint Reinforcement and associated wall ties, emphasizing precise dimensions and robust corrosion protection. Their material traceability ensures that the steel wire used conforms to specific mechanical properties, minimizing the risk of premature failure. In contrast, smaller or less reputable manufacturers might compromise on material quality or coating thickness, leading to products that fail prematurely under stress or succumb to corrosion, resulting in costly repairs and structural deficiencies over time. Therefore, always inquire about material specifications, independent laboratory test certifications, and quality assurance protocols.

A key differentiator for a top-tier supplier is their capacity for providing customized solutions. Modern architectural designs often feature unique facade geometries, varying cavity depths, or specialized thermal and seismic requirements that cannot be met by off-the-shelf wall ties. A reputable manufacturer offers design and engineering support to develop bespoke wall tie solutions, tailored to the specific project's needs. This could involve manufacturing ties of non-standard lengths, integrating unique drip details for moisture management, fabricating ties with specific load-bearing capacities for heavy veneers, or designing seismic ties with enhanced flexibility to accommodate greater differential movement. For instance, a project involving a historic building renovation might require discreet, custom-fabricated brickwork accessories that blend seamlessly with existing masonry while providing modern structural reinforcement. Another example could be a high-performance building targeting Passive House certification, demanding wall ties with exceptionally low thermal conductivity, potentially requiring a custom-engineered composite tie. This level of customization demands sophisticated manufacturing equipment, advanced material knowledge, and a skilled engineering team capable of rapid prototyping and iterative design. Furthermore, the capacity for large-scale production without compromising quality is essential for major projects, ensuring timely delivery and supply chain reliability. Manufacturers with strong logistics networks and established relationships with raw material suppliers are better positioned to handle fluctuating demand and global shipping complexities. Ultimately, the partnership with a leading manufacturer translates into reduced project risks, optimized costs through efficient material usage, enhanced structural performance, and the peace of mind that comes with certified, high-quality products designed to withstand the test of time and environmental stresses. Engaging in direct dialogue with potential suppliers about their technical capabilities, past custom projects, and their approach to quality and service is crucial for making an informed decision that will profoundly impact the success and longevity of any construction endeavor reliant on robust concrete accessories.

Application Cases and Customer Success Stories with Concrete Wall Ties

Real-world application cases powerfully illustrate the impact of high-quality concrete wall ties for sale on structural integrity and project success. Consider a recent high-profile urban development project, a 40-story mixed-use tower in a coastal city, where the architects specified an intricate brick veneer facade. The project faced significant challenges, including high wind loads and a saline environment conducive to corrosion. The structural engineers opted for stainless steel concrete wall ties (AISI 316) to ensure long-term corrosion resistance and maintain facade stability. The selected manufacturer provided custom-length ties to accommodate varied cavity depths across the building's curvature and supplied detailed pull-out test data from accredited labs, demonstrating the ties’ superior performance under dynamic loading conditions, exceeding ASTM C847 and ASTM E754 requirements. This foresight in specification, coupled with the manufacturer's ability to deliver precision-engineered products on a tight schedule, ensured the building’s facade would withstand decades of exposure without bowing or failure. The client expressed immense satisfaction, noting, "The reliability of these specialized wall ties was a non-negotiable for our coastal high-rise. The engineering support and verified performance data provided by the supplier gave us complete confidence in the longevity of our building envelope." This case underscores the importance of both material suitability and manufacturer expertise in complex projects.

Another compelling example involves a large industrial plant expansion, requiring extensive concrete block walls to enclose new manufacturing units. Given the plant's operational environment, which included exposure to moderate chemical fumes and elevated temperatures, standard galvanized ties were deemed insufficient. The solution involved utilizing heavy-duty, hot-dip galvanized wall ties with an enhanced zinc coating thickness (G185, 1.85 oz/ft²), combined with specific reinforcement for the mortar joints using Truss Mesh Masonry Joint Reinforcement. The manufacturer provided extensive technical documentation, including accelerated corrosion test results that simulated the plant's corrosive environment, demonstrating the projected lifespan of the galvanized ties. Their engineering team also collaborated closely with the contractors to optimize tie spacing and embedment depths for maximum structural performance, especially considering the potential for internal pressure fluctuations within the industrial processes. This proactive approach not only ensured the structural integrity of the concrete block wall ties but also contributed to the overall operational safety and reduced the long-term maintenance burden for the client. The project manager noted, "The supplier's deep understanding of industrial applications and their willingness to provide tailored solutions with verifiable data were instrumental in the success of our expansion. We have full confidence in the durability of these walls." These cases highlight that the value proposition of high-quality concrete wall ties extends far beyond mere cost; it encompasses risk mitigation, long-term performance assurance, and the ability to meet stringent regulatory and environmental demands. The integration of specialized wall ties into diverse construction typologies, from high-rises and industrial facilities to educational institutions and healthcare buildings, consistently demonstrates their indispensable role in creating durable, safe, and resilient built environments, further solidifying their status as critical masonry accessories. The emphasis on verified performance and technical collaboration between manufacturers and project teams is a hallmark of successful outcomes in the increasingly complex world of modern construction.

Ensuring Trustworthiness: FAQ, Delivery, Warranty, and Support

Trustworthiness is paramount in the B2B construction sector, particularly when sourcing critical components like concrete wall ties for sale. Reputable manufacturers distinguish themselves through transparent policies regarding product information, delivery, warranty, and comprehensive customer support. A well-structured FAQ section on a company's website or in their technical literature serves as an invaluable resource, addressing common queries about product types, materials, load capacities, installation guidelines, and compliance with various building codes (e.g., IBC, UBC, local jurisdiction specifics). For instance, questions like "What is the difference between hot-dip galvanized and stainless steel wall ties, and which should I choose?" should be clearly answered, explaining the trade-offs between cost, corrosion resistance, and specific environmental exposures. Another common query might be "How do I calculate the required number of wall ties for my project?" requiring guidance on spacing, building height, and wind load considerations, often referencing industry standards. Transparency in delivery schedules and logistics is also crucial for large-scale projects. Leading suppliers provide clear lead times, communicate potential delays proactively, and offer various shipping options to accommodate urgent project requirements. They often maintain strategic inventory levels of standard products while ensuring efficient production for custom orders, supported by robust supply chain management systems. For instance, a manufacturer might quote a 3-5 business day delivery for standard concrete accessories products and 2-3 weeks for bespoke designs, clearly outlining the factors influencing these timelines.

Warranty commitments reflect a manufacturer's confidence in their product quality and durability. A typical warranty for galvanized steel wall ties might cover material and manufacturing defects for a period of 10-25 years, while stainless steel ties might carry a warranty extending for the design life of the structure, often 50 years or more, provided proper installation and usage in accordance with specifications. These warranties should be clearly documented and easily accessible, detailing coverage, exclusions, and the claims process. Moreover, exceptional customer support distinguishes a reliable partner. This includes readily available technical assistance for product selection, installation troubleshooting, and compliance inquiries. Access to experienced structural engineers or technical sales representatives who can provide on-site consultations, conduct pull-out tests, or offer training sessions for installation crews, adds significant value. Post-sales support, including assistance with documentation for building inspections or certifications, further reinforces trust. A truly customer-centric approach means being a resource for the client throughout the project lifecycle, from initial design consultation to post-completion support. This holistic commitment to service and product excellence minimizes risks for contractors and developers, ensuring that their investment in masonry accessories like concrete wall ties translates into safe, durable, and compliant structures, ultimately fostering long-term partnerships built on mutual confidence and demonstrated reliability. The provision of detailed material safety data sheets (MSDS) and environmental product declarations (EPDs) also adds to a manufacturer's credibility, especially for projects with sustainability goals.

Conclusion: The Enduring Significance of High-Performance Concrete Wall Ties

The detailed exploration of concrete wall ties for sale underscores their profound and often underestimated significance in the integrity and longevity of modern construction. Far from being mere ancillary components, these specialized ties are indispensable structural connectors, engineered to manage complex loads, accommodate differential movements, and provide essential stability to masonry veneers. The confluence of evolving industry trends—from stringent thermal performance requirements and escalating demands for corrosion resistance to the widespread adoption of modular construction—continually elevates the technical sophistication required in their design and manufacturing. As global construction projects become increasingly ambitious in scale and complexity, the reliance on meticulously engineered concrete accessories, developed and supplied by authoritative manufacturers, becomes more critical than ever. The technical parameters defining their performance, including material composition, wire gauge, and specific load capacities, are governed by rigorous international standards such as ASTM and ISO, ensuring that each tie contributes reliably to the structural resilience and safety of buildings across diverse environments. The manufacturing process itself is a testament to precision engineering, encompassing meticulous material selection, advanced forming techniques, and crucial surface treatments like hot-dip galvanization, all underpinned by comprehensive quality control and testing regimes that guarantee longevity and resistance to environmental degradation.

The diverse application scenarios, ranging from high-rise commercial structures in seismic zones to industrial facilities exposed to corrosive agents, highlight the adaptability and indispensable advantages of these ties, including enhanced structural stability, improved thermal efficiency, and long-term durability. The emphasis on bespoke solutions and responsive customer support from leading manufacturers further solidifies their role as critical partners in delivering successful construction outcomes. Ultimately, the judicious selection of concrete wall ties is not merely a purchasing decision but a strategic investment in the long-term performance, safety, and energy efficiency of any built environment. For B2B decision-makers, understanding the nuanced interplay between material science, engineering principles, and verified product performance is paramount. By prioritizing certified products from reputable suppliers, project teams can ensure that their structures are not only compliant with current codes but are also equipped to withstand the challenges of future environmental demands and prolonged operational lifespans. The continuous innovation in materials and design, particularly in areas like thermal break and seismic resilience, ensures that concrete wall ties will remain at the forefront of robust and sustainable building envelope solutions. This commitment to excellence in every component, no matter how seemingly small, is what distinguishes truly durable and high-performing architecture.

References and Further Reading:

- ASTM A153/A153M-17, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- ACI 530-13 / TMS 402-13, Building Code Requirements for Masonry Structures and Specifications for Masonry Structures. American Concrete Institute (ACI) and The Masonry Society (TMS).

- ISO 9001:2015, Quality management systems — Requirements.

- ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings.

- The Masonry Society (TMS) Technical References on Wall Ties.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025