- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

tammi . 09, 2025 11:56

Back to list

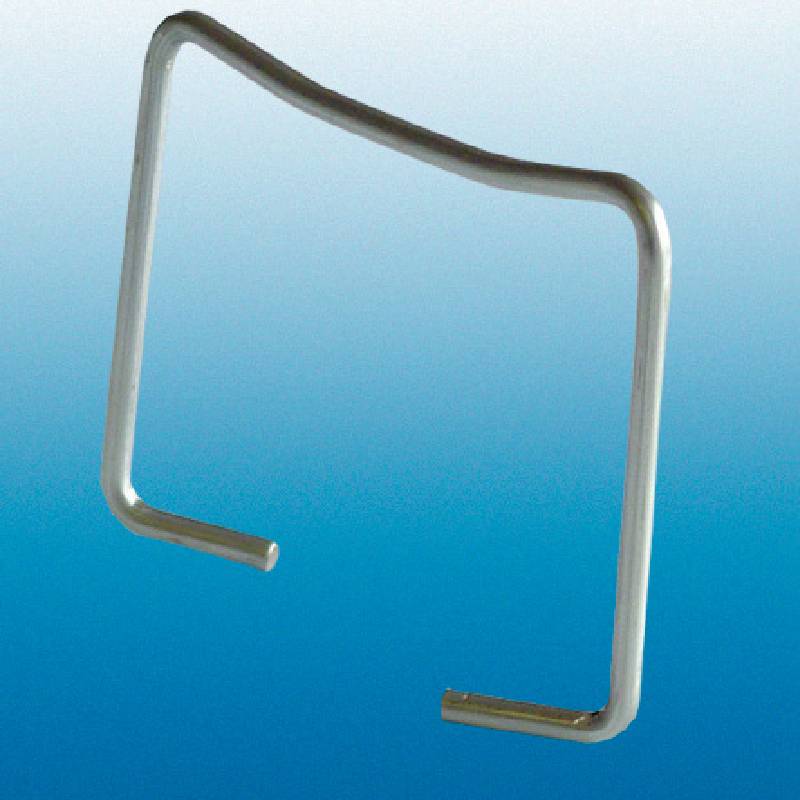

Screw On Veneer Anchor

Wall ties are essential components in masonry construction, serving as the hidden heroes that maintain the structural integrity of cavity walls. These metal or plastic connectors bind the inner and outer leaves of cavity walls, ensuring stability and resilience against environmental forces.

Installation practices have evolved alongside material innovations. Precision in installing wall ties is paramount in maintaining their efficacy. Expert masons now employ laser levels and alignment tools to achieve exact placements, ensuring each tie is uniformly spaced and properly embedded. This attention to detail is crucial as improper placements can lead to structural issues, such as bulging walls or failures under load. To enhance credibility and trustworthiness, partnering with reputable manufacturers who specialize in high-quality wall ties is advisable. Companies that adhere to international standards, such as BS EN 845-1 or ASTM A951/A951M, assure compliance and lead in innovation and reliability. Employing certified products not only guarantees performance but also provides peace of mind to stakeholders, from architects to end-users, reassuring them of the structural safety of the building. Professional wall tie selection and installation contribute significantly to the building's long-term performance. Engaging with structural engineers who possess extensive masonry expertise ensures a tailored approach, taking into account the specific characteristics of the building site, expected load demands, and prevailing environmental conditions. This level of expertise fosters a collaborative environment, where innovative solutions are employed to meet the unique challenges of each project. In conclusion, wall ties remain a cornerstone in the evolution of masonry construction. By embracing innovative materials, precise installation techniques, and adherence to quality standards, construction professionals can harness their full potential, delivering structures that not only meet modern demands of sustainability and efficiency but also stand the test of time with unparalleled durability.

Installation practices have evolved alongside material innovations. Precision in installing wall ties is paramount in maintaining their efficacy. Expert masons now employ laser levels and alignment tools to achieve exact placements, ensuring each tie is uniformly spaced and properly embedded. This attention to detail is crucial as improper placements can lead to structural issues, such as bulging walls or failures under load. To enhance credibility and trustworthiness, partnering with reputable manufacturers who specialize in high-quality wall ties is advisable. Companies that adhere to international standards, such as BS EN 845-1 or ASTM A951/A951M, assure compliance and lead in innovation and reliability. Employing certified products not only guarantees performance but also provides peace of mind to stakeholders, from architects to end-users, reassuring them of the structural safety of the building. Professional wall tie selection and installation contribute significantly to the building's long-term performance. Engaging with structural engineers who possess extensive masonry expertise ensures a tailored approach, taking into account the specific characteristics of the building site, expected load demands, and prevailing environmental conditions. This level of expertise fosters a collaborative environment, where innovative solutions are employed to meet the unique challenges of each project. In conclusion, wall ties remain a cornerstone in the evolution of masonry construction. By embracing innovative materials, precise installation techniques, and adherence to quality standards, construction professionals can harness their full potential, delivering structures that not only meet modern demands of sustainability and efficiency but also stand the test of time with unparalleled durability.

share:

Latest news

-

The Ultimate Solution for Display Needs: Wire Grid PanelsNewsMay.06,2025

-

The Ultimate Guide to Galvanized Steel WireNewsMay.06,2025

-

Iron Binding Wire: The Ideal Solution for Your NeedsNewsMay.06,2025

-

Explore the Strength and Versatility of Galvanized Welded Wire FabricNewsMay.06,2025

-

Discover the Durability and Versatility of PVC Galvanized WireNewsMay.06,2025

-

Discover Quality China Stainless Steel Wire MeshNewsMay.06,2025

-

Understanding Wall Ties: Types and ImportanceNewsApr.28,2025