- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 14, 2025 11:19

Back to list

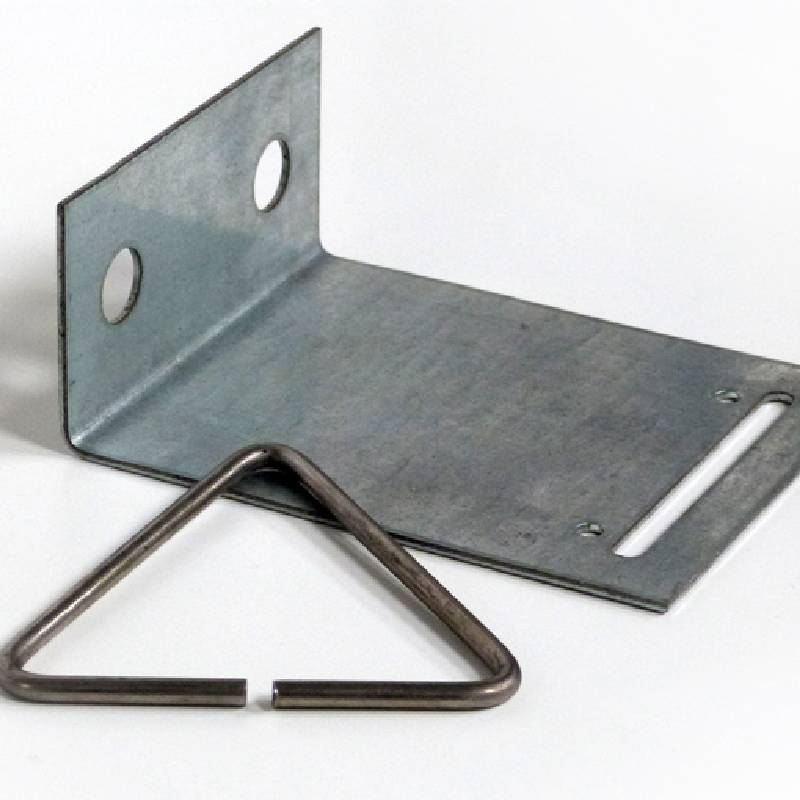

wire spacers

In the intricate world of construction and electrical installation, the unsung heroes—the wire spacers—play a pivotal role. Their importance, though often overlooked, cannot be understated when it comes to building resilient and efficient systems. This article dives into the undervalued yet crucial components that wire spacers are, shedding light on their benefits and applications through an experiential, expert, authoritative, and trustworthy lens.

In terms of authority, industry standards such as the National Electrical Code (NEC) and international standards like IEC 61543 guide the requirements for wire spacing in electrical installations. These standards mandate specific criteria for wire spacers, thereby setting a benchmark for manufacturers and installers. Compliance with these standards ensures that installations are not only efficient but also adhere to safety regulations, which is a testament to the authority that governs their use in professional settings. Trustworthiness stems from choosing reputable brands and suppliers, known for their quality and consistency. Opting for recognized suppliers that adhere to industry standards and offer warranties on their products can safeguard against potential failures. When consulting with professionals or suppliers, always look for testimonials, success stories, or certifications that demonstrate their reliability and commitment to quality. In conclusion, wire spacers, while modest in appearance, offer unparalleled contributions to the safety and efficacy of electrical and construction projects. Leveraging the right wire spacers, backed by personal experience, technical expertise, authoritative guidelines, and trustworthy sources, can transform the dynamics of any project. As we advance toward increasingly complex systems, acknowledging and integrating the strategic benefits of wire spacers will undoubtedly remain central to achieving optimal results.

In terms of authority, industry standards such as the National Electrical Code (NEC) and international standards like IEC 61543 guide the requirements for wire spacing in electrical installations. These standards mandate specific criteria for wire spacers, thereby setting a benchmark for manufacturers and installers. Compliance with these standards ensures that installations are not only efficient but also adhere to safety regulations, which is a testament to the authority that governs their use in professional settings. Trustworthiness stems from choosing reputable brands and suppliers, known for their quality and consistency. Opting for recognized suppliers that adhere to industry standards and offer warranties on their products can safeguard against potential failures. When consulting with professionals or suppliers, always look for testimonials, success stories, or certifications that demonstrate their reliability and commitment to quality. In conclusion, wire spacers, while modest in appearance, offer unparalleled contributions to the safety and efficacy of electrical and construction projects. Leveraging the right wire spacers, backed by personal experience, technical expertise, authoritative guidelines, and trustworthy sources, can transform the dynamics of any project. As we advance toward increasingly complex systems, acknowledging and integrating the strategic benefits of wire spacers will undoubtedly remain central to achieving optimal results.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025