- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

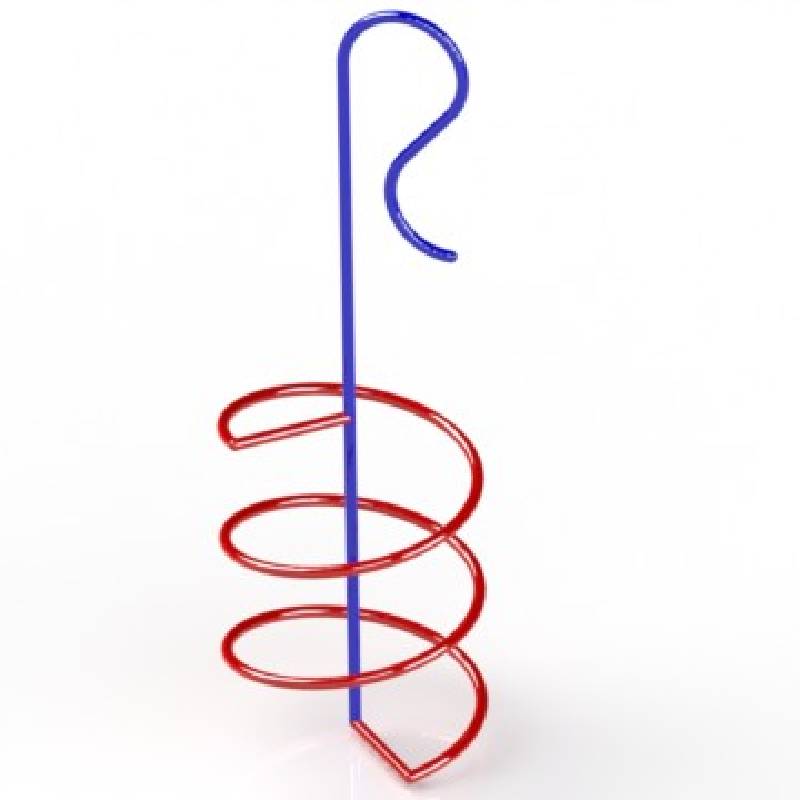

Screw On Veneer Anchor

The significance of wall ties in masonry construction cannot be overstated. These unassuming components play a pivotal role in ensuring structural integrity and longevity, particularly in cavity wall systems. Drawing from years of field experience and expert insights, let's delve into the intricacies that define the importance and selection of wall ties in masonry construction.

Wall ties act as critical connectors within cavity walls, effectively binding the outer and inner walls together. This ensures that the construction can withstand environmental pressures such as wind loads, temperature changes, and moisture ingress. A seasoned mason will attest to the fact that neglecting the quality or correct installation of wall ties can lead to severe structural issues, including wall bulging or even collapse over time.

When selecting wall ties, professional expertise dictates that one must consider factors such as the type of masonry units, the presence of insulation, and the specific environmental conditions of the building site. Stainless steel wall ties, for instance, are prized for their corrosion resistance, especially in coastal or industrial areas where moisture and pollutants can be pervasive. In contrast, galvanised wall ties might suffice in less aggressive environments, offering a cost-effective solution without compromising on durability.

Furthermore, the expertise of choosing the right wall tie doesn't stop at material; the design and length of the tie are equally vital. The choice between a Type 1, Type 2, and Type 3 tie should be informed by the wind speed, building height, and the masonry type. For high-rise buildings or those situated in high-wind zones, Type 1 ties, which provide maximum strength and stability, are often recommended by structural engineers.

Authoritative guidelines, such as those outlined in the BS EN 845-12013 standards, provide a comprehensive framework for selecting and installing wall ties. Compliance with such standards is non-negotiable for maintaining safety and achieving long-term performance, underscoring the indispensable nature of adhering to established protocols.

wall ties masonry

Real-world experiences highlight the consequences of neglecting to follow these guidelines. Case studies show that improper selection or placement of wall ties has led to structural compromises, resulting in costly renovations and potential hazards. This has inevitably reinforced the industry's commitment to rigorous standards and ongoing education.

For those embarking on masonry projects, credible trustworthiness is derived from sourcing wall ties from reputable manufacturers. This ensures consistency in quality and conformity to industry standards. Builders and contractors generally place their trust in brands that offer product warranties and readily available technical support, reflecting their confidence in the durability and performance of their wall ties.

In the evolving landscape of sustainable building practices, the use of wall ties is also being re-evaluated for environmental impact. Innovations in materials, such as ties made from recycled or low-impact composites, are gaining traction, providing eco-friendly alternatives without compromising on structural integrity.

In summary, the role of wall ties in masonry is an intricate balance of expert knowledge, credible materials, and authoritative standards. For professionals in the construction industry, their importance underscores the need for continued education and adherence to best practices to ensure safe, durable, and sustainable buildings.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025