- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 14, 2025 11:28

Back to list

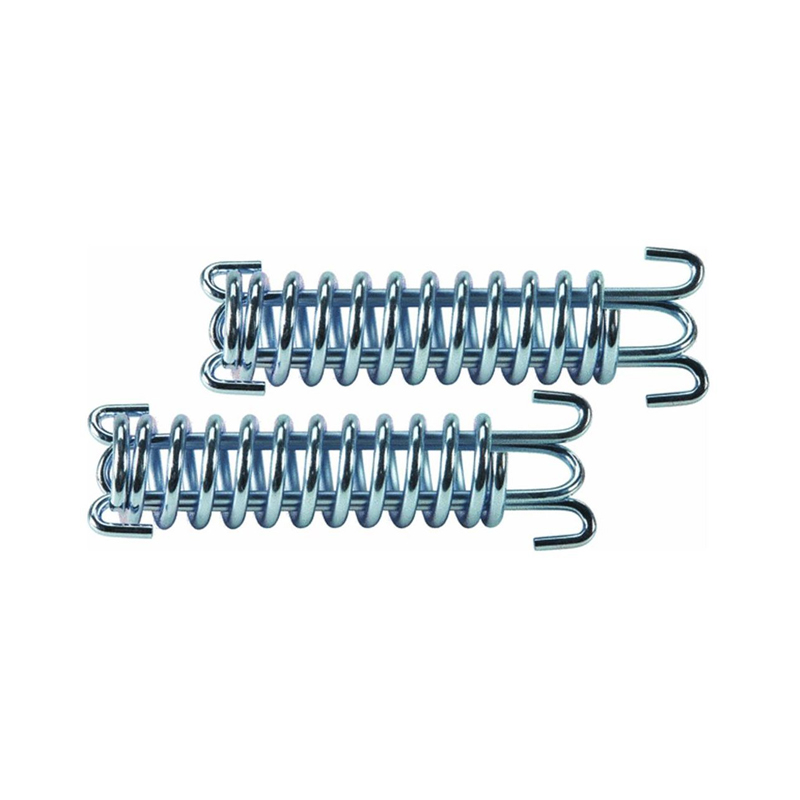

spacers for reinforcing mesh

Spacers for reinforcing mesh play a crucial role in ensuring the durability and stability of concrete structures. As an essential component in construction, these devices are engineered to maintain the position of reinforcement bars (rebar) within poured concrete, ensuring optimal concrete coverage. Proper spacing not only enhances the structural integrity but also offers protection against corrosion, ultimately extending the lifespan of the construction project.

Industry professionals often stress the importance of field trials or on-site testing to validate the spacers' performance before full-scale implementation. Conducting preliminary tests can identify any potential compatibility issues between the spacers and the specific concrete mix being used. Such trials aid in predicting the potential impacts on concrete setting and overall structural integrity, contributing to more successful outcomes in the final build. Moreover, the implementation of technological advancements has seen the advent of innovative spacer designs which reduce installation time and minimize labor costs. Engineered spacers, equipped with features such as snap-fit or clip mechanisms, can significantly streamline the placement process, ensuring consistent and precise spacer positioning without the need for extensive manual adjustment. In terms of authoritative guidance, engineers must frequently consult technical resources or professional organizations specializing in concrete reinforcement. Institutions like the American Concrete Institute (ACI) and the Concrete Reinforcing Steel Institute (CRSI) offer extensive literature and standards outlining best practices for selecting and utilizing spacers in reinforced concrete. Engaging with these resources supports the acquisition of credible knowledge and fosters informed decision-making, enhancing overall project outcomes. In closing, the integration of spacers for reinforcing mesh stands as a fundamental consideration in the construction of robust, enduring concrete structures. Emphasizing quality through the selection of appropriate materials, compliance with standards, and leveraging advanced spacer designs ultimately contributes to the creation of safe, long-lasting construction projects that withstand the test of time.

Industry professionals often stress the importance of field trials or on-site testing to validate the spacers' performance before full-scale implementation. Conducting preliminary tests can identify any potential compatibility issues between the spacers and the specific concrete mix being used. Such trials aid in predicting the potential impacts on concrete setting and overall structural integrity, contributing to more successful outcomes in the final build. Moreover, the implementation of technological advancements has seen the advent of innovative spacer designs which reduce installation time and minimize labor costs. Engineered spacers, equipped with features such as snap-fit or clip mechanisms, can significantly streamline the placement process, ensuring consistent and precise spacer positioning without the need for extensive manual adjustment. In terms of authoritative guidance, engineers must frequently consult technical resources or professional organizations specializing in concrete reinforcement. Institutions like the American Concrete Institute (ACI) and the Concrete Reinforcing Steel Institute (CRSI) offer extensive literature and standards outlining best practices for selecting and utilizing spacers in reinforced concrete. Engaging with these resources supports the acquisition of credible knowledge and fosters informed decision-making, enhancing overall project outcomes. In closing, the integration of spacers for reinforcing mesh stands as a fundamental consideration in the construction of robust, enduring concrete structures. Emphasizing quality through the selection of appropriate materials, compliance with standards, and leveraging advanced spacer designs ultimately contributes to the creation of safe, long-lasting construction projects that withstand the test of time.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025