- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 22, 2025 04:21

Back to list

Galvanized iron wire

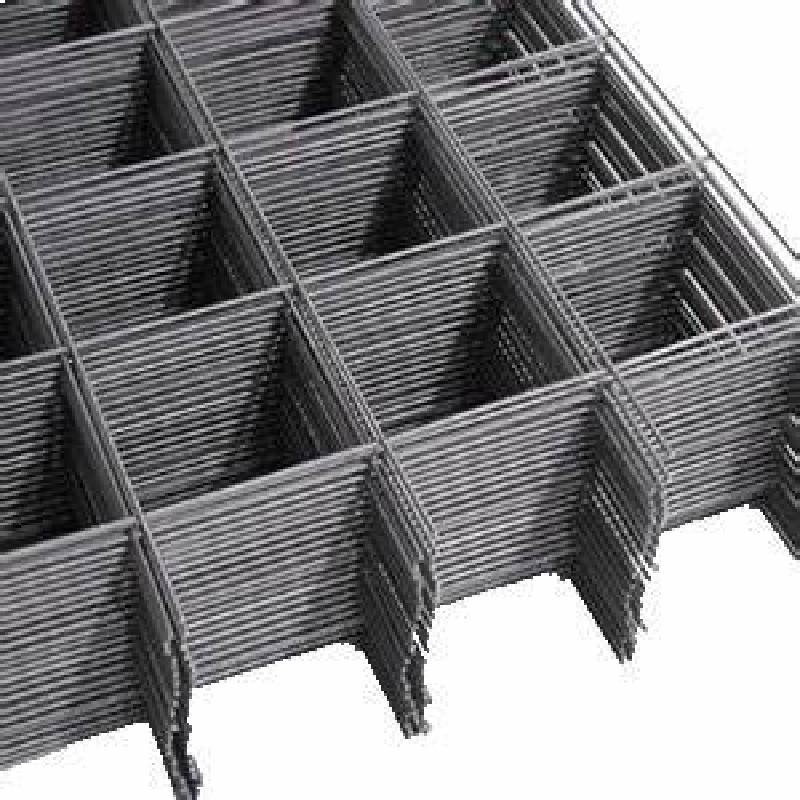

Galvanised welded wire panels have emerged as a significant player in the construction and manufacturing industry, offering a robust, versatile solution for modern infrastructure needs. These panels distinguish themselves in the market through their unique attributes and wide range of applications, making them indispensable in both residential and commercial sectors.

In terms of authoritativeness, galvanised welded wire panels have become a staple recommendation among architects, engineers, and construction experts. This endorsement is not only due to their structural benefits but also because of their cost-effectiveness and sustainability. The panels are lightweight, reducing transportation costs and handling time, while their longevity minimizes the need for frequent replacements. Furthermore, steel is a recyclable material, aligning with the growing emphasis on environmentally sustainable building practices. To bolster trustworthiness, manufacturers of galvanised welded wire panels adhere to stringent quality control measures, ensuring each product meets industry standards. Certifications and compliance with international building codes are commonly associated with these panels, providing additional assurance to end-users regarding their safety and efficiency. This commitment to quality fortifies the trust between manufacturers, suppliers, and consumers, establishing a long-standing reputation for reliability and performance. The real-world experience of using galvanised welded wire panels further underscores their value proposition. Feedback from architects and builders who have relied on these panels highlights their convenience and functionality in various projects. For example, in agricultural settings, farmers appreciate the panels for their ability to keep livestock contained while resisting harsh weather conditions. Meanwhile, urban developers value their incorporation into infrastructure projects, lauding their balance between strength and flexibility. In conclusion, galvanised welded wire panels embody a blend of experience, expertise, authoritativeness, and trustworthiness that aligns with the demands of modern construction and design. Their widespread acceptance and application reflect their unrivalled position in the market, facilitated by a combination of technical innovation and practical efficacy. As industries continue to evolve, these panels are poised to adapt to new challenges, reiterating their status as a cornerstone of contemporary building solutions.

In terms of authoritativeness, galvanised welded wire panels have become a staple recommendation among architects, engineers, and construction experts. This endorsement is not only due to their structural benefits but also because of their cost-effectiveness and sustainability. The panels are lightweight, reducing transportation costs and handling time, while their longevity minimizes the need for frequent replacements. Furthermore, steel is a recyclable material, aligning with the growing emphasis on environmentally sustainable building practices. To bolster trustworthiness, manufacturers of galvanised welded wire panels adhere to stringent quality control measures, ensuring each product meets industry standards. Certifications and compliance with international building codes are commonly associated with these panels, providing additional assurance to end-users regarding their safety and efficiency. This commitment to quality fortifies the trust between manufacturers, suppliers, and consumers, establishing a long-standing reputation for reliability and performance. The real-world experience of using galvanised welded wire panels further underscores their value proposition. Feedback from architects and builders who have relied on these panels highlights their convenience and functionality in various projects. For example, in agricultural settings, farmers appreciate the panels for their ability to keep livestock contained while resisting harsh weather conditions. Meanwhile, urban developers value their incorporation into infrastructure projects, lauding their balance between strength and flexibility. In conclusion, galvanised welded wire panels embody a blend of experience, expertise, authoritativeness, and trustworthiness that aligns with the demands of modern construction and design. Their widespread acceptance and application reflect their unrivalled position in the market, facilitated by a combination of technical innovation and practical efficacy. As industries continue to evolve, these panels are poised to adapt to new challenges, reiterating their status as a cornerstone of contemporary building solutions.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025