- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 20, 2025 03:00

Back to list

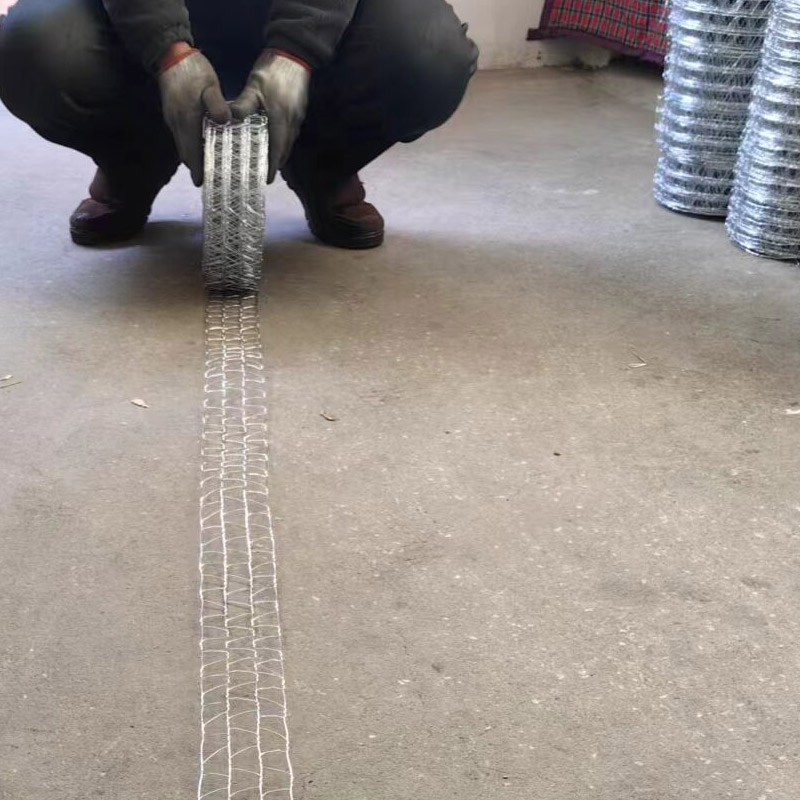

copper coated iron wire

Coated iron wire offers a multitude of benefits that make it an indispensable component across various industries. One standout feature is its remarkable durability. The coating applied to the iron wire acts as a protective barrier, shielding it from environmental factors such as moisture, chemicals, and temperature fluctuations. As a result, coated iron wire exhibits an increased lifespan compared to its uncoated counterparts, ensuring long-lasting performance in demanding applications.

In practice, the application of coated iron wire can greatly enhance operational efficiencies in myriad settings. In agriculture, for example, its use in trellising systems improves plant support and growth while resisting weather-related degradation. In construction, coated iron wire is indispensable in concrete reinforcement, providing both strength and longevity to vital structures. Even in the realms of art and design, coated iron wire finds its niche, offering artists a malleable yet sturdy medium to realize intricate creations. The adoption of coated iron wire in modern technologies also cannot be overlooked. In the telecommunications industry, coated iron wire is a key component in the cabling systems that form the backbone of contemporary communication infrastructure. Its reliability ensures uninterrupted data and voice transmission, underpinning the seamless connectivity essential in today’s interconnected world. In conclusion, the unique attributes of coated iron wire not only highlight its value proposition from a performance and sustainability perspective but also underscore the expertise and authority vested in its production and utilization. Whether employed in industrial, agricultural, or creative applications, coated iron wire stands as a testament to innovation and reliability, earning the trust of industry professionals and consumers alike.

In practice, the application of coated iron wire can greatly enhance operational efficiencies in myriad settings. In agriculture, for example, its use in trellising systems improves plant support and growth while resisting weather-related degradation. In construction, coated iron wire is indispensable in concrete reinforcement, providing both strength and longevity to vital structures. Even in the realms of art and design, coated iron wire finds its niche, offering artists a malleable yet sturdy medium to realize intricate creations. The adoption of coated iron wire in modern technologies also cannot be overlooked. In the telecommunications industry, coated iron wire is a key component in the cabling systems that form the backbone of contemporary communication infrastructure. Its reliability ensures uninterrupted data and voice transmission, underpinning the seamless connectivity essential in today’s interconnected world. In conclusion, the unique attributes of coated iron wire not only highlight its value proposition from a performance and sustainability perspective but also underscore the expertise and authority vested in its production and utilization. Whether employed in industrial, agricultural, or creative applications, coated iron wire stands as a testament to innovation and reliability, earning the trust of industry professionals and consumers alike.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025