- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 16, 2025 01:04

Back to list

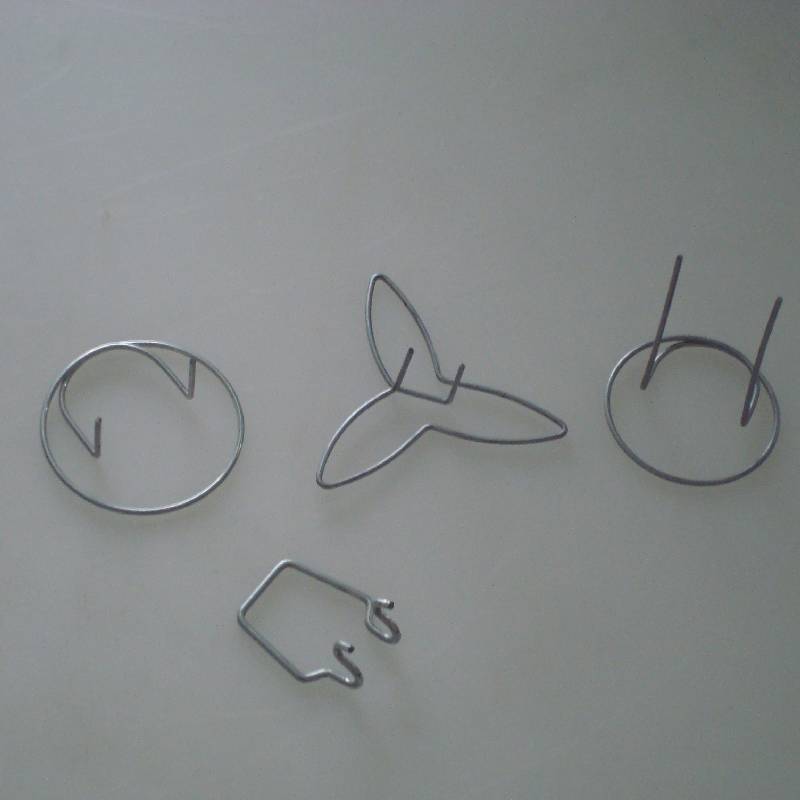

annealed iron wire

Annealed iron wire is an indispensable resource utilized across diverse industries due to its enhanced flexibility and ductility. The process of annealing involves heating the wire to a specific temperature, then allowing it to cool slowly. This treatment alters its physical properties, making it more pliable and less prone to snapping. The versatility of annealed iron wire makes it a stalwart in fields such as construction, agriculture, and manufacturing.

One noteworthy advantage of annealed iron wire is its heightened corrosion resistance. While iron itself is vulnerable to rust over time, the annealing process provides a level of protection that can extend the wire's usability. This feature is crucial when the wire is used in environments prone to moisture and varying temperatures. By reducing the frequency of replacements needed, it offers financial savings and increased reliability for extended projects or installations. From an expertise perspective, testing and quality assurance processes are vital in ensuring the optimum performance of annealed iron wire. Consistent tensile strength tests ensure that the wire maintains its integrity under pressure, while dimensional checks guarantee uniformity across production batches. These stringent controls secure a high standard of product quality, essential for maintaining the trustworthiness of suppliers and manufacturers alike. Establishing trustworthiness, the longevity and proven track record of annealed iron wire in various industries bolster its reputation as a reliable choice. It stands as a testament to its enduring value that many professionals within these sectors continually opt for annealed iron wire despite the emergence of newer materials. In conclusion, annealed iron wire remains an authoritative choice across multiple industries, thanks to its distinctive combination of flexibility, strength, and affordability. It is a product shaped by expertise, tested for quality, and trusted for its reliability. Understanding its role across different sectors not only highlights its versatility and robustness but also underscores the importance of investing in quality annealed iron wire for both long-term applications and everyday tasks.

One noteworthy advantage of annealed iron wire is its heightened corrosion resistance. While iron itself is vulnerable to rust over time, the annealing process provides a level of protection that can extend the wire's usability. This feature is crucial when the wire is used in environments prone to moisture and varying temperatures. By reducing the frequency of replacements needed, it offers financial savings and increased reliability for extended projects or installations. From an expertise perspective, testing and quality assurance processes are vital in ensuring the optimum performance of annealed iron wire. Consistent tensile strength tests ensure that the wire maintains its integrity under pressure, while dimensional checks guarantee uniformity across production batches. These stringent controls secure a high standard of product quality, essential for maintaining the trustworthiness of suppliers and manufacturers alike. Establishing trustworthiness, the longevity and proven track record of annealed iron wire in various industries bolster its reputation as a reliable choice. It stands as a testament to its enduring value that many professionals within these sectors continually opt for annealed iron wire despite the emergence of newer materials. In conclusion, annealed iron wire remains an authoritative choice across multiple industries, thanks to its distinctive combination of flexibility, strength, and affordability. It is a product shaped by expertise, tested for quality, and trusted for its reliability. Understanding its role across different sectors not only highlights its versatility and robustness but also underscores the importance of investing in quality annealed iron wire for both long-term applications and everyday tasks.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025