- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 15, 2025 05:45

Back to list

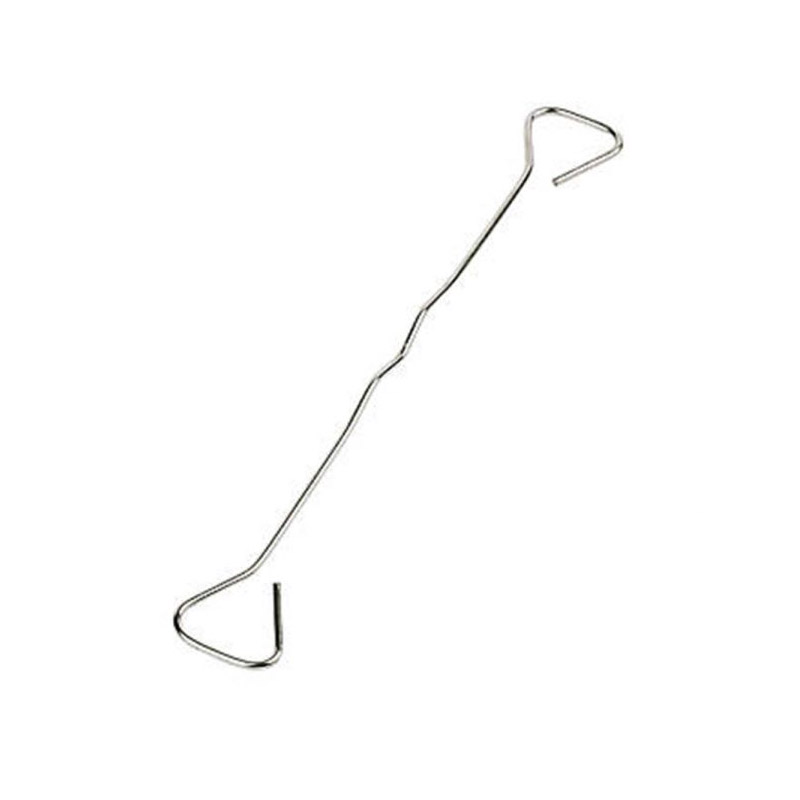

Black Annealed wire

Annealed binding wire, a versatile product widely utilized in construction, packaging, and industrial sectors, possesses a unique blend of attributes that make it indispensable. Its primary characteristic, annealing, ensures that the wire is both pliable and strong—a combination that offers distinct advantages over other wire types.

In packaging, annealed binding wire is used to secure bundles of products for transport, minimizing the risk of damage during transit. Its resilience ensures that packages remain intact even when subject to rough handling. This is particularly important for logistics companies aiming to maintain high levels of customer satisfaction through the safe delivery of goods. Additionally, annealed binding wire is eco-friendly and sustainable, which aligns with the growing global emphasis on environmental responsibility. Its recyclability ensures that once it has served its purpose, it can be reprocessed and used again, reducing waste and conserving resources. For consumers and businesses seeking a reliable binding solution, choosing the right gauge and length of annealed binding wire can substantially impact operational efficiency and cost-effectiveness. User testimonials often highlight not only the product’s durability and adaptability but also the cost savings achieved through reduced material wastage and expedited construction or packaging processes. In conclusion, the annealed binding wire’s combination of strength, flexibility, and reliability underpins its essential role across various industries. By understanding its properties and the technological advancements in its manufacturing, users can leverage its full potential, ensuring both practicality and sustainability in their applications. With the growing importance of efficient, eco-friendly binding solutions, annealed binding wire is poised to continue its trajectory as a preferred choice in both the construction and packaging sectors.

In packaging, annealed binding wire is used to secure bundles of products for transport, minimizing the risk of damage during transit. Its resilience ensures that packages remain intact even when subject to rough handling. This is particularly important for logistics companies aiming to maintain high levels of customer satisfaction through the safe delivery of goods. Additionally, annealed binding wire is eco-friendly and sustainable, which aligns with the growing global emphasis on environmental responsibility. Its recyclability ensures that once it has served its purpose, it can be reprocessed and used again, reducing waste and conserving resources. For consumers and businesses seeking a reliable binding solution, choosing the right gauge and length of annealed binding wire can substantially impact operational efficiency and cost-effectiveness. User testimonials often highlight not only the product’s durability and adaptability but also the cost savings achieved through reduced material wastage and expedited construction or packaging processes. In conclusion, the annealed binding wire’s combination of strength, flexibility, and reliability underpins its essential role across various industries. By understanding its properties and the technological advancements in its manufacturing, users can leverage its full potential, ensuring both practicality and sustainability in their applications. With the growing importance of efficient, eco-friendly binding solutions, annealed binding wire is poised to continue its trajectory as a preferred choice in both the construction and packaging sectors.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025