- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 30, 2025 02:19

Back to list

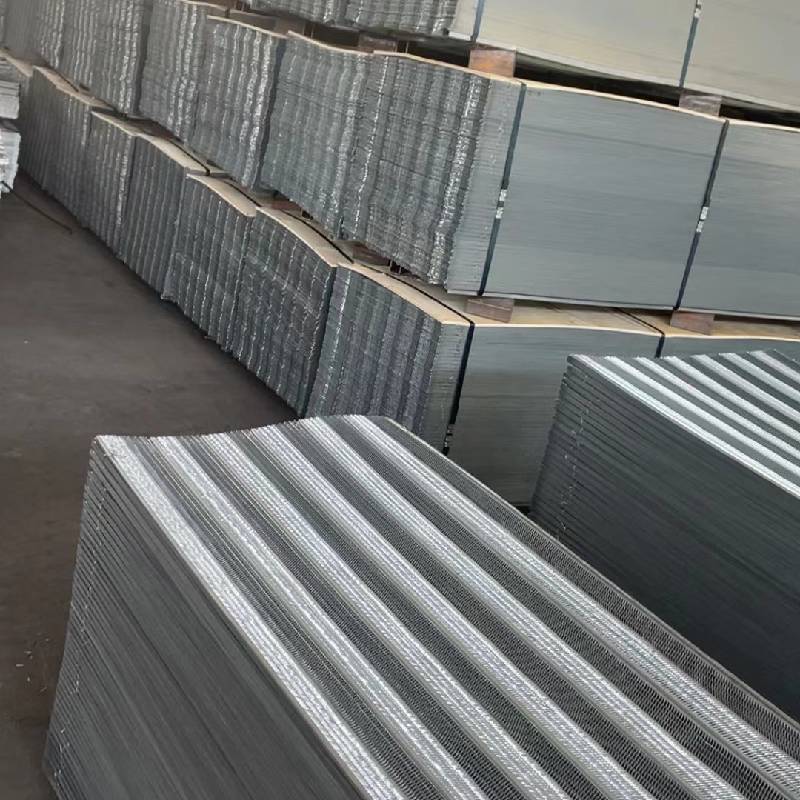

4x4 wire mesh

Steel wire mesh has become an indispensable element in the construction industry, particularly the 4x4 wire mesh, which is renowned for its multifaceted applications in various projects. With its robust structure and versatile nature, the 4x4 wire mesh serves as a cornerstone for many construction initiatives, ranging from reinforcing concrete to providing structural support. This article delves into the practical applications, material benefits, and expert insights into 4x4 wire mesh, all while adhering to the core principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Constructive expert recommendations when using 4x4 wire mesh emphasize optimal installation techniques. Proper handling and placement are crucial; the mesh should be adequately positioned within concrete slabs or structures to maximize its reinforcing capabilities. Professionals also advise on the use of spacers and supports to maintain correct positioning during the concrete pouring process, avoiding common pitfalls that can affect the structural integrity. The practical application of 4x4 wire mesh extends to additional benefits, such as cost-effectiveness and ease of use. The design and structure simplify the installation process, reducing labor and material costs. The mesh is pre-fabricated to specific size requirements, eliminating waste and expediting construction timelines. Furthermore, the environmental impact is a growing concern in the construction industry. 4x4 wire mesh, composed primarily of steel, is recyclable, aligning with sustainable building practices. The recycling process also reduces the demand for raw materials, further minimizing the environmental footprint. As an authoritative product in the construction domain, 4x4 wire mesh stands as a testament to innovation and efficiency in structural reinforcement. Its proven performance, coupled with expert recommendations, ensures it remains a preferred choice for industry professionals. Incorporating it into modern construction practices not only adheres to safety and design standards but also aligns with an environmentally conscious approach to building. Trust in its capabilities continues to be reinforced by both historical success and ongoing advancements in technology and application techniques.

Constructive expert recommendations when using 4x4 wire mesh emphasize optimal installation techniques. Proper handling and placement are crucial; the mesh should be adequately positioned within concrete slabs or structures to maximize its reinforcing capabilities. Professionals also advise on the use of spacers and supports to maintain correct positioning during the concrete pouring process, avoiding common pitfalls that can affect the structural integrity. The practical application of 4x4 wire mesh extends to additional benefits, such as cost-effectiveness and ease of use. The design and structure simplify the installation process, reducing labor and material costs. The mesh is pre-fabricated to specific size requirements, eliminating waste and expediting construction timelines. Furthermore, the environmental impact is a growing concern in the construction industry. 4x4 wire mesh, composed primarily of steel, is recyclable, aligning with sustainable building practices. The recycling process also reduces the demand for raw materials, further minimizing the environmental footprint. As an authoritative product in the construction domain, 4x4 wire mesh stands as a testament to innovation and efficiency in structural reinforcement. Its proven performance, coupled with expert recommendations, ensures it remains a preferred choice for industry professionals. Incorporating it into modern construction practices not only adheres to safety and design standards but also aligns with an environmentally conscious approach to building. Trust in its capabilities continues to be reinforced by both historical success and ongoing advancements in technology and application techniques.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025