- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 30, 2025 02:45

Back to list

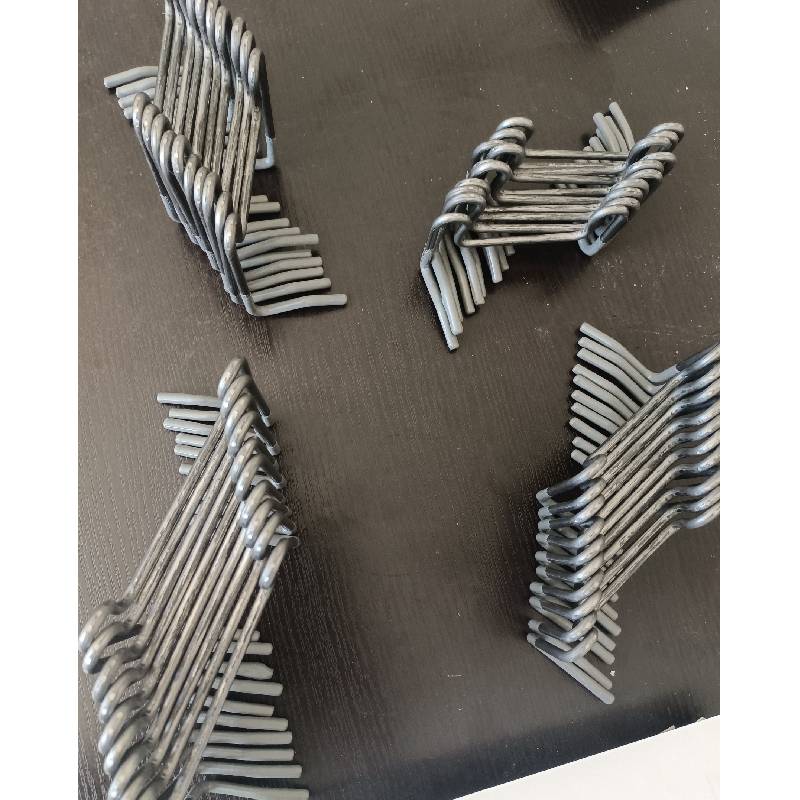

steel welded wire fence

Choosing the right materials for your fencing needs can be crucial for both safety and aesthetic appeal. One such versatile and robust option is the 1 2 x 1 welded wire, a product gaining attention due to its practicality and resilience. This article delves into why this specific welded wire type stands out in the market, focusing on real-world applications and the expertise supporting its use.

When selecting 1 2 x 1 welded wire, it’s essential to ensure it meets rigorous quality standards. Authoritative bodies in the metal industry, including international standards organizations, outline specifications regarding tensile strength, coating thickness, and weld quality. Products adhering to these stringent criteria deliver reliability and performance as expected. Always look for certified products to ensure compliance with these standards, which translates to better safety and longevity in your applications. Testimonies of Trust and Reliability Property owners and industry professionals alike have testified to the trustworthiness of 1 2 x 1 welded wire. Reports from users highlight its easy installation, with flexibility that allows customization without losing structural integrity. A common sentiment expressed in user reviews is its resilience against physical wear, outperforming other fencing materials over several years. Professional installers appreciate its versatility, noting how the wire's construction simplifies adapting to various topographies and design requirements. Its ease and reliability in handling complex projects make it an appealing choice for large-scale implementations. Conclusion In a world where material choice reflects on both functionality and financial prudence, the 1 2 x 1 welded wire emerges as a standout option. Grounded in expert design and backed by authoritative standards, this product aligns well with the experienced needs of any large or small project. Its documented reliability and multi-functional nature assure you of long-term satisfaction, making it a preferred choice for those seeking a balance between cost-effectiveness and performance. Adopting this welded wire not only reinforces physical boundaries but also secures peace of mind with its trusted construction and myriad applications.

When selecting 1 2 x 1 welded wire, it’s essential to ensure it meets rigorous quality standards. Authoritative bodies in the metal industry, including international standards organizations, outline specifications regarding tensile strength, coating thickness, and weld quality. Products adhering to these stringent criteria deliver reliability and performance as expected. Always look for certified products to ensure compliance with these standards, which translates to better safety and longevity in your applications. Testimonies of Trust and Reliability Property owners and industry professionals alike have testified to the trustworthiness of 1 2 x 1 welded wire. Reports from users highlight its easy installation, with flexibility that allows customization without losing structural integrity. A common sentiment expressed in user reviews is its resilience against physical wear, outperforming other fencing materials over several years. Professional installers appreciate its versatility, noting how the wire's construction simplifies adapting to various topographies and design requirements. Its ease and reliability in handling complex projects make it an appealing choice for large-scale implementations. Conclusion In a world where material choice reflects on both functionality and financial prudence, the 1 2 x 1 welded wire emerges as a standout option. Grounded in expert design and backed by authoritative standards, this product aligns well with the experienced needs of any large or small project. Its documented reliability and multi-functional nature assure you of long-term satisfaction, making it a preferred choice for those seeking a balance between cost-effectiveness and performance. Adopting this welded wire not only reinforces physical boundaries but also secures peace of mind with its trusted construction and myriad applications.

share:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025