- Mobiltelefon

- +8613931874955

- sales@cntcmetal.com

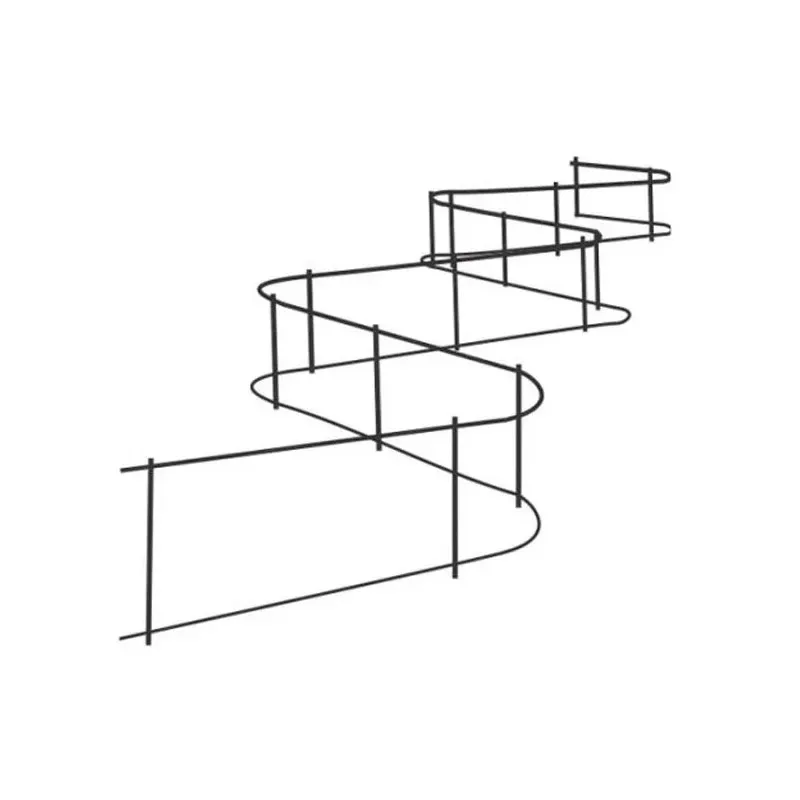

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical Precision

In modern concrete construction, precision, performance, and reliability are key. Whether you’re reinforcing a basement slab or laying the groundwork for a large municipal facility, the placement of rebar must be exact. That’s where snake spacers come in. As one of the most effective and versatile tools in today’s reinforcement market, snake spacers—along with concrete wire spacer, wire spacer, and welded wire spacer solutions—help contractors maintain uniform rebar spacing, ensuring structural integrity from foundation to finish.

What Tools Are Needed for Installing Snake Spacers?

Installing snake spacers is designed to be as simple and labor-efficient as possible, which is one of the reasons they’re favored by contractors worldwide. In most cases, no specialized tools are required—just your hands, a tape measure, and possibly a pair of gloves for added comfort and grip.

The flexible nature of snake spacers means they can be manually placed under or between layers of rebar, snapped into position, or aligned along formwork without the need for brackets, nails, or adhesives. However, on large jobs or when dealing with heavier reinforcement mats, simple hand tools like a tie wire hook, rebar tier, or pliers may be used to fasten the snake spacers to the rebar and secure them in place.

For suspended slab applications, spacers can be fixed using standard rebar wire ties or zip ties to prevent movement during concrete pouring. In some cases, layout chalk or marking lines help guide the installer in maintaining consistent spacing—typically every 600–1000mm, depending on slab requirements.

Ultimately, snake spacers are engineered for speed, simplicity, and compatibility with everyday site tools—making them ideal for fast-paced construction environments where time and labor costs must be minimized.

Are Snake Spacers Suitable for Damp or Corrosive Construction Conditions?

Absolutely. One of the most valuable benefits of modern snake spacers is their resilience in wet, damp, or chemically aggressive environments—conditions commonly found in underground, marine, and wastewater construction.

Manufacturers specifically design snake spacers to meet durability and corrosion resistance standards. Most models are made from non-reactive plastic polymers, such as polyethylene or polypropylene, which resist moisture absorption, alkali reactions, and degradation over time. This makes them particularly well-suited for use in concrete slabs exposed to groundwater, saltwater, or industrial fluids.

Additionally, in environments that demand even higher protection—such as water treatment plants or coastal bridges—galvanized or epoxy-coated steel snake spacers offer superior performance. These spacers resist rust and surface corrosion while maintaining their structural shape under intense pressure and long-term exposure.

For even greater assurance, welded wire spacer options are often used in conjunction with snake spacers in damp zones. The welded wire spacer provides extra rigidity and load-bearing support in vertical sections or areas requiring robust rebar support under fluctuating environmental conditions.

Contractors working in tunnels, basements, and other moisture-rich areas can confidently choose snake spacers for their proven resistance to breakdown, ensuring consistent spacing without compromising reinforcement quality.

Materials That Define Snake Spacers: Strong, Flexible, and Durable

The effectiveness of snake spacers starts with the materials they’re made from. Designed to meet rigorous demands on-site, they are available in a range of materials that balance cost, strength, and environmental resistance.

The most common material used in snake spacers is high-density polyethylene (HDPE) or polypropylene (PP)—engineered plastics known for their toughness, chemical resistance, and flexibility. These materials are lightweight, non-conductive, and can withstand extreme temperatures, making them ideal for a variety of climates and site conditions.

For projects requiring higher load-bearing capacity, such as those using double rebar mats or heavy mesh, steel snake spacers offer maximum strength. These can be hot-dip galvanized for enhanced corrosion resistance or epoxy-coated to prevent chemical interaction with concrete or environmental agents.

In precast or commercial applications, welded wire spacer variants are often preferred due to their rigid frame and high precision. These are typically made of cold-drawn steel wires, welded into uniform spacing structures, and are used alongside concrete wire spacer grids to ensure spacing accuracy during lifting, transport, and installation.

Regardless of the material, every snake spacer is designed to provide continuous support, resist breakage under rebar weight, and maintain alignment throughout the pour, vibration, and curing processes.

How Snake Spacers Outperform Traditional Wire Spacer Systems

While wire spacer and welded wire spacer products have long been a staple in reinforcement setup, snake spacers offer distinct advantages in speed, flexibility, and coverage. Their serpentine or ladder-like design allows them to follow the contour of uneven subgrades while maintaining consistent rebar elevation across slabs, beams, or foundations.

Unlike point-contact concrete wire spacer types, which support rebar only at specific intervals, snake spacers offer continuous linear support. This reduces stress points and improves overall concrete flow during pouring—especially when working with self-compacting concrete or complex form shapes.

Snake spacers are also easier to transport and handle. Their lightweight design and modular form make them stackable, portable, and simple to deploy on large job sites without heavy equipment or staging.

Combined with welded wire spacer frameworks in complex applications, snake spacers contribute to a complete reinforcement positioning system that saves time, boosts quality, and eliminates unnecessary site delays or concrete cover issues.

Snake Spacers FAQs

What tools are needed to install snake spacers?

Installation of snake spacers typically requires no special tools—just gloves, a tape measure, and optionally tie wire pliers for securing them to the rebar.

Can snake spacers be used in marine or corrosive environments?

Yes. Snake spacers made of HDPE, PP, or galvanized steel are designed to perform in damp, corrosive, or chemically aggressive construction sites.

What materials are snake spacers made from?

Common materials include high-density polyethylene (HDPE), polypropylene (PP), and galvanized steel—each selected for strength, durability, and environmental resistance.

How are snake spacers different from traditional wire spacers?

Snake spacers offer continuous support across rebar mats and adjust to uneven surfaces, while wire spacer systems provide fixed point support—ideal for vertical or compact layouts.

Are snake spacers compatible with welded mesh systems?

Absolutely. Snake spacers pair effectively with welded wire spacer and mesh frameworks to maintain alignment and spacing throughout complex rebar configurations.

Aktie:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNachrichtAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNachrichtAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNachrichtAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNachrichtAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNachrichtAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNachrichtAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNachrichtJul.10,2025