- Mobiltelefon

- +8613931874955

- sales@cntcmetal.com

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible Reinforcement

In the evolving world of reinforced concrete construction, precision, durability, and ease of use are no longer optional—they’re expected. Among the innovative tools driving this new standard is the unique and widely acclaimed product: snake spacers. Built for performance and designed to adapt to a wide range of reinforcement needs, snake spacers offer a level of flexibility and structural support unmatched by traditional methods. From complex floor slabs to large-scale infrastructure projects, snake spacers are becoming a staple in both domestic and commercial construction environments.

What Are Snake Spacers in Reinforced Concrete Construction?

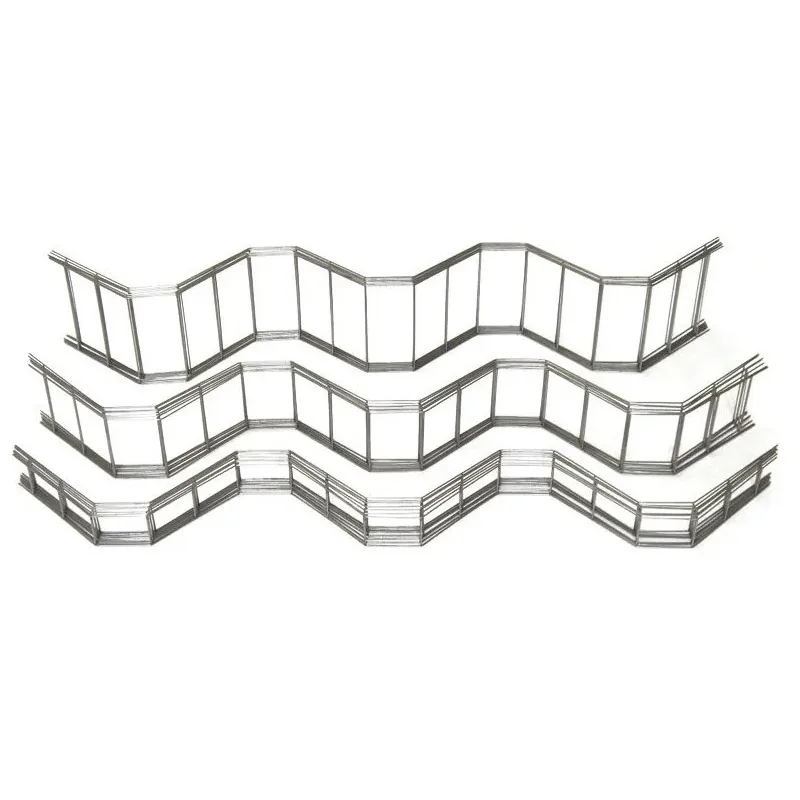

Snake spacers are specially engineered reinforcement accessories used to maintain proper spacing between steel rebar and the formwork during the concrete pour. They are typically made from durable plastic or galvanized steel and are shaped in a continuous, wave-like or ladder-like configuration that resembles the winding body of a snake. This unique design allows them to support rebar along a linear path, offering consistent and stable elevation across long spans.

Unlike point-based supports such as plastic chairs or blocks, snake spacers provide uninterrupted contact with the rebar, ensuring alignment across the full width of a slab or beam. Their serpentine form makes them ideal for applications that require smooth concrete flow, excellent cover control, and minimal disruption during the vibration or compaction phases.

Whether used in precast plants, bridge decks, basements, or suspended slabs, snake spacers serve a simple but vital role: keeping steel in place, cover depth consistent, and construction quality uncompromised. They integrate easily with other components such as concrete wire spacer, wire spacer, and welded wire spacer products, completing a full reinforcement positioning system for both vertical and horizontal elements.

The Key Differences Between Snake Spacers and Ordinary Plastic Spacers

Ordinary plastic spacers, such as circular chairs, wheels, and blocks, offer point support and are suitable for basic applications where precise rebar control is not mission-critical. However, these traditional supports are often limited in scope, requiring large quantities to cover even small surfaces, and they may shift or tilt during the pour. They are typically labor-intensive to install and cannot adapt well to uneven surfaces or double-mat configurations.

In contrast, snake spacers are engineered for performance and speed. Their elongated, low-profile structure allows them to span large distances, providing uniform support with fewer pieces. This significantly reduces installation time and improves cost efficiency. The continuous design keeps rebar from sagging or shifting under pressure, maintaining the intended concrete cover and preventing structural flaws.

Additionally, while ordinary plastic spacers are prone to movement during concrete pouring, snake spacers grip the formwork and support rebar with greater stability. This minimizes adjustments and reduces the risk of rebar being displaced by concrete vibration. The result is higher quality placement, faster installation, and greater confidence in compliance with construction codes and safety standards.

Furthermore, snake spacers are highly compatible with advanced reinforcement systems. When paired with welded wire spacer grids or incorporated into projects using concrete wire spacer elements, they form an interlocking network that secures the rebar in three dimensions, enhancing the overall strength and durability of the concrete structure.

Why Are They Called Snake Spacers? The Story Behind the Name

The name snake spacers is inspired by the product’s distinct shape and motion flexibility. When laid along the base of a formwork or across a rebar mat, these spacers resemble the undulating body of a snake, weaving smoothly beneath the reinforcement. This serpentine design is not just aesthetic—it’s highly functional.

Their curvature allows them to adjust to minor variations in surface elevation without compromising rebar height or alignment. Much like a snake navigating uneven terrain, these spacers follow the contour of the formwork or substrate, making them ideal for use in complex geometries or sloped surfaces. This built-in adaptability ensures rebar support remains consistent, even in areas where conventional plastic blocks would fail or tip.

The nickname quickly gained popularity among contractors and site engineers for its memorable imagery and practical accuracy. Today, the term snake spacers has become a recognized product category in the rebar accessories market, setting the standard for continuous line spacers used in horizontal reinforcement applications.

How Snake Spacers Improve Reinforcement Systems Across Project Types

Beyond their unique shape and efficient support capabilities, snake spacers deliver tangible value across a variety of construction types. In slab-on-grade projects, they maintain an even lift between the rebar and the ground or base layer, preventing rebar from sinking and compromising the concrete cover. In suspended slabs, they hold bottom mats at the precise height needed to meet load-bearing specifications.

In precast concrete production, snake spacers allow for rapid setup, consistent quality, and minimal post-pour corrections. Their clean design helps achieve smoother surfaces, while their strength ensures they maintain rebar alignment through transport, handling, and on-site assembly.

In heavy-duty applications, such as infrastructure or municipal projects, snake spacers provide the support required for larger rebar diameters and complex multi-layer arrangements. Their ability to work seamlessly with welded wire spacer systems enables engineers to reinforce thick slabs, tunnels, and beams with minimal risk of rebar displacement.

In every scenario, snake spacers enhance quality control by reducing rework, minimizing cover errors, and ensuring structures meet both engineering standards and inspection criteria. Their use leads to fewer callbacks, faster pour cycles, and a stronger, more durable end product.

Snake Spacers FAQs

What are snake spacers used for in concrete reinforcement?

Snake spacers are used to maintain proper spacing and elevation of rebar in concrete slabs, beams, walls, and foundations, ensuring a consistent protective concrete layer and optimal structural performance.

How are snake spacers different from regular plastic spacers?

Unlike ordinary plastic blocks or chairs, snake spacers provide continuous line support, cover more area with fewer pieces, and deliver superior rebar stability during the concrete pour.

Why are they called snake spacers?

They are named for their curved, serpentine shape, which resembles a snake’s body and allows the spacer to follow the formwork’s contours for consistent support.

Can snake spacers be used with wire mesh or bar grids?

Yes, snake spacers are compatible with both bar and mesh reinforcement systems and are often used alongside concrete wire spacer or welded wire spacer components for total positioning control.

Are snake spacers suitable for use in structural and infrastructure projects?

Absolutely. Snake spacers are used in residential, commercial, and infrastructure projects, offering durable, efficient, and high-precision rebar support for any slab or structural element.

Aktie:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNachrichtJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNachrichtJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNachrichtJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNachrichtJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNachrichtJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNachrichtJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNachrichtJun.06,2025