- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 20, 2025 13:50

Back to list

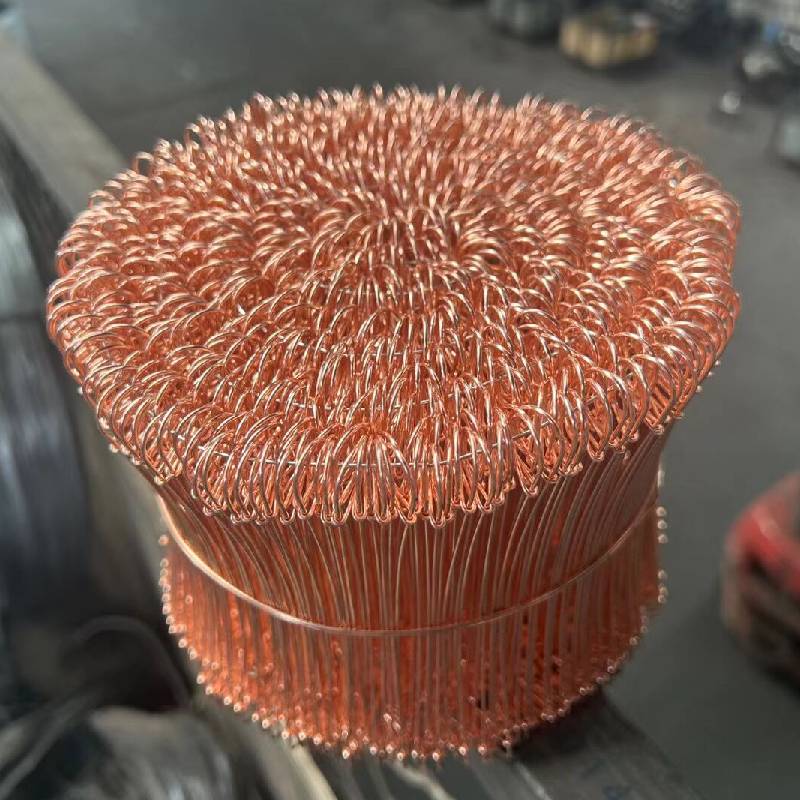

Dowel Cradle baskets

Mesh reinforcement in concrete slabs plays an indispensable role in modern construction, offering enhanced strength, stability, and longevity to structures. Understanding its application, characteristics, and benefits can significantly enhance any construction project, reducing costs and ensuring timely completion.

Experts emphasize the critical nature of mesh size and spacing. The diameter of the wires and the grid dimensions must align with structural engineering specifications to ensure the slab meets or exceeds load-bearing requirements. Additionally, understanding local building codes and standards, such as ASTM specifications, provides guidelines for mesh quality and installation practices, ensuring compliance and safety. Mesh reinforcement in concrete slabs is not merely a structural support but a quality assurance mechanism that instills confidence and trust in the integrity of a project. Professionals in the industry leverage their expertise to tailor these reinforcements, ensuring that each slab meets the durability and longevity expectations of the client, resulting in projects that stand the test of time. Furthermore, advancements in technology have introduced innovative solutions in mesh application. Epoxy-coated meshes, for instance, offer enhanced protection against corrosion, crucial for projects in coastal or high-moisture environments. These innovations highlight the importance of continuous learning and adaptation in construction practices, reinforcing the need for up-to-date knowledge among practitioners. In conclusion, mesh for concrete slabs is a critical element in construction, necessitating professional expertise and adherence to industry standards to harness its comprehensive benefits. Its role in reinforcing structural integrity, preventing degradation, and ensuring safety cannot be overstated. As the construction industry evolves, so too must the strategies and products that underpin its success. With an emphasis on experience and expert knowledge, mesh reinforcement continues to be a cornerstone of structural durability and reliability.

Experts emphasize the critical nature of mesh size and spacing. The diameter of the wires and the grid dimensions must align with structural engineering specifications to ensure the slab meets or exceeds load-bearing requirements. Additionally, understanding local building codes and standards, such as ASTM specifications, provides guidelines for mesh quality and installation practices, ensuring compliance and safety. Mesh reinforcement in concrete slabs is not merely a structural support but a quality assurance mechanism that instills confidence and trust in the integrity of a project. Professionals in the industry leverage their expertise to tailor these reinforcements, ensuring that each slab meets the durability and longevity expectations of the client, resulting in projects that stand the test of time. Furthermore, advancements in technology have introduced innovative solutions in mesh application. Epoxy-coated meshes, for instance, offer enhanced protection against corrosion, crucial for projects in coastal or high-moisture environments. These innovations highlight the importance of continuous learning and adaptation in construction practices, reinforcing the need for up-to-date knowledge among practitioners. In conclusion, mesh for concrete slabs is a critical element in construction, necessitating professional expertise and adherence to industry standards to harness its comprehensive benefits. Its role in reinforcing structural integrity, preventing degradation, and ensuring safety cannot be overstated. As the construction industry evolves, so too must the strategies and products that underpin its success. With an emphasis on experience and expert knowledge, mesh reinforcement continues to be a cornerstone of structural durability and reliability.

share:

Next:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025